The direct expenses of food recalls, including product retrieval, lost sales, root cause investigations, and legal costs, amount to approximately $10 million per incident, some exceeding far more. With the rising food recalls in 2025, are your development pipelines resilient to this financial threat? This article discusses emerging innovations that can help you minimize these recalls, even prevent them, for your product lines.

Food Recall Trends 2025

In Q1 alone, dairy led the surge with nearly 400 recalls out of 1,363, closely followed by fresh produce with 264 recalls. Market predictions show dairy will remain under intense pressure in Q2 as well. Meanwhile, recalls in food categories like nuts and seeds, cocoa, and poultry are expected to increase by 47%, 162%, and 80% in Q2 2025.

The table below provides a detailed monthly analysis of food categories from January to March 2025, including product recalls and forecasted trends, with comparisons to the same period in the previous year.

Undeclared allergens were the leading cause of food recalls in 2024, accounting for 34.1% of the total. Common allergens include nuts, milk, eggs, soy, and wheat. The Centers for Disease Control and Prevention (CDC) estimates that about 32 million Americans have food allergies, including 5.6 million children under age 18.

Meanwhile, microbiological contamination, like Listeria and Salmonella, was the primary reason for dairy product recalls. Below is a detailed breakdown of the root causes behind recalls in 2024.

Financial threats aren’t the only challenges a company faces due to food recalls. This can result in lost consumer loyalty, a damaged brand reputation, and a decline in market share.

In some cases, neglecting food safety protocols has resulted in businesses shutting down for good and company executives facing life sentences.

Emerging Solutions Companies Should Adopt to Prevent Food Recalls

In 2008, a quiet storm was brewing inside the Peanut Corporation of America. Despite internal tests repeatedly flagging salmonella contamination, its president, Stewart Parnell, made a chilling decision. He instructed his team to ship the products anyway. “I go thru this about once a week…I will hold my breath…again,” he wrote in an email.

What followed was one of the deadliest foodborne illness outbreaks in U.S. history, sickening nearly 20,000 people and causing at least nine deaths. The fallout was devastating: a billion-dollar market loss, thousands of product recalls, and finally, a life sentence for Parnell in 2015. The case underscores the fine line between negligence and fraud.

Fast-forward to today, the stakes remain just as high. However, emerging technologies are helping brands prevent microbial growth in food, rapidly detect contamination, and conduct root cause analysis across complex supply chains—ultimately reducing the risk of costly food recalls. This article examines five technologies that companies can implement across their production processes to protect their products from this threat.

Implementing Advanced Traceability and Food Safety Systems

Brands Can Use Ecotrace To Pinpoint Shipments Responsible For Contamination

Ecotrace leverages blockchain, machine learning, IoT, big data, and data science technologies to track products from origin to end consumer

Ecotrace’s traceability solution enables stakeholders to conduct root cause analysis across the supply chain in the agrifood sector, including cattle and poultry.

For example, suppose a batch of contaminated lettuce is discovered at a retail store. In that case, Ecotrace can quickly trace it back to its origin, such as a farm, and pinpoint the shipment responsible for the contamination. This minimizes the size and scope of the recall, reducing food wastage.

| Founding Year | 2018 |

| Headquarters | Sao Paulo, Brazil |

| Total Funding Amount | $1.1M |

| Last Funding Round/Amount | Seed/$600K |

| Website | ecotrace.info |

Collaboration with this innovative startup will also help brands prepare for the new FDA Digital Food Traceability Rule, which takes effect as of January 2026.

Bio2coat’s 100% Natural Coatings Prevent Contamination While Boosting Sustainability

Although synthetic materials are more effective for food preservation and packaging, they disrupt the sustainability goals of brands and leach harmful substances into food.

An emerging food safety startup, Bio2coat, has developed a series of 100% natural, edible coatings for food products to address this industry challenge.

| Founding Year | 2020 |

| Headquarters | Catalonia, Spain |

| Total Funding Amount | Publicly Not Known |

| Last Funding Round/Amount | Non-Equity Assistance/Publicly Not Known |

| Website | http://bio2coat.com/en/ |

These coatings are applied to the surface of fresh fruits and vegetables, helping to extend their shelf life by safeguarding against contamination, moisture loss, and oxidative damage.

In 2023, it was recognized as the best emerging company at the Foodtech Startup Forum, receiving a €3,000 prize to support its business development.

These startups are well-positioned for rapid growth and have the potential to introduce disruptive technology in the next 2-3 years. They can help brands clearly communicate their commitment to safety, gaining a competitive edge.

Explore the full list of emerging food traceability and safety startups by clicking on the links below. We have compared these startups based on their novel technologies and funding stages to assess their potential for co-creation and Mergers and Acquisitions (M&A).

Browse Full List of Food Traceability and Safety Startups

Author’s Note: Avoiding recalls and litigation are not the only reasons brands should prioritize food safety and traceability. They can also use it as a powerful marketing tool, positioning themselves as consumer-centric brands and trusted partners.

Utilizing Rapid Contamination Detection Technologies In the Production Processes

Current pathogen testing methods can take up to 7 days to yield results. Additionally, they can only be performed in a lab, and not in the production area. This is primarily due to the complexity of sample preparation and the inability to detect contaminants in real-time. Companies adhering to strict food safety standards often face costly production halts due to these delays.

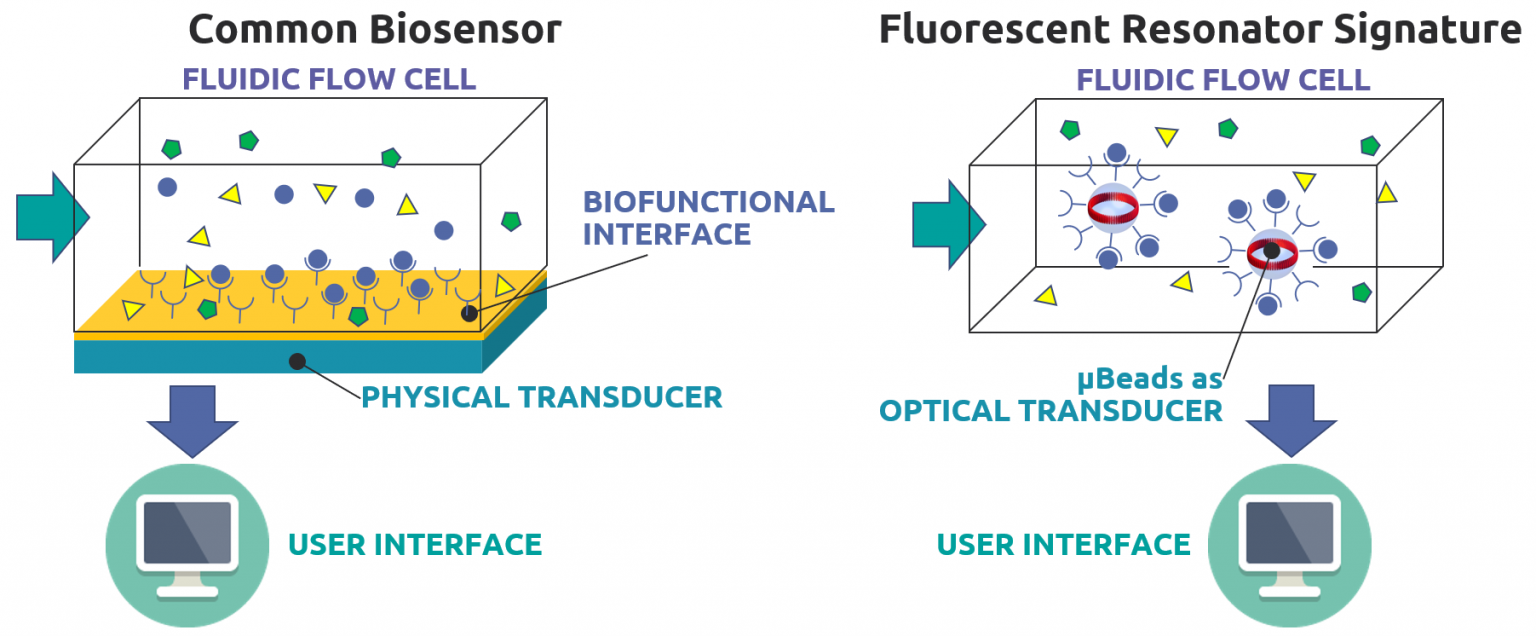

A startup named FluiDect is overcoming this industrial limitation with a new biosensor that detects pathogens in complex liquids without sample preparation. The Fluorescent Resonator Signature (FRS) technology provides real-time data, allowing operators to respond immediately to contamination and optimize their processes.

The technology works with various complex substances, including raw milk, wastewater, and cream juice, making it adaptable across multiple food categories.

We spoke with Dr. Tobias Schröter, CEO of FluiDect, to gain a deeper understanding of their technology and its commercial feasibility. Here’s the full interview:

Adopt Antimicrobial Packaging Innovations For Extended Shelf Life Throughout The Supply Chain

In the summer of 2022, Lyons Magnus, a well-known name behind many ready-to-drink (RTD) plant-based beverages, found itself in the middle of a massive product recall.

What triggered it? Not allergens. Not formulation. But something deceptively simple: packaging.

Consumers were buying oat milks and protein shakes, trusting that they’ll stay fresh until the printed expiry date on the bottle. But behind the scenes, the packaging failed to meet commercially sterile standards, creating conditions that allowed harmful pathogens to grow.

This was a wake-up call for the F&B industry. It isn’t just about what goes into the bottle — it is also about how that bottle holds up under pressure, on shelves, and in supply chains. The incident prompted the industry to reassess the integrity of packaging, particularly for shelf-stable products.

Companies like Purac and DMK Deutsches Milchkontor have developed smart solutions that help prevent packaging-related microbial contamination in fresh dairy products and plant-based alternatives like vegan cheese.

Purac Biochem’s Antimicrobial Polymer Sheet Contains No Chemical Preservatives

Purac Biochem’s antimicrobial polymer sheet replaces traditional chemical preservatives in dairy packaging. This vinyl polymer surface layer contains C8-C16 acyl lactylates that prevent bacterial growth. The antimicrobial effect remains stable throughout the supply chain, enhancing food safety and extending shelf life. This innovation ensures freshness in dairy products while meeting consumer demand for fewer additives.

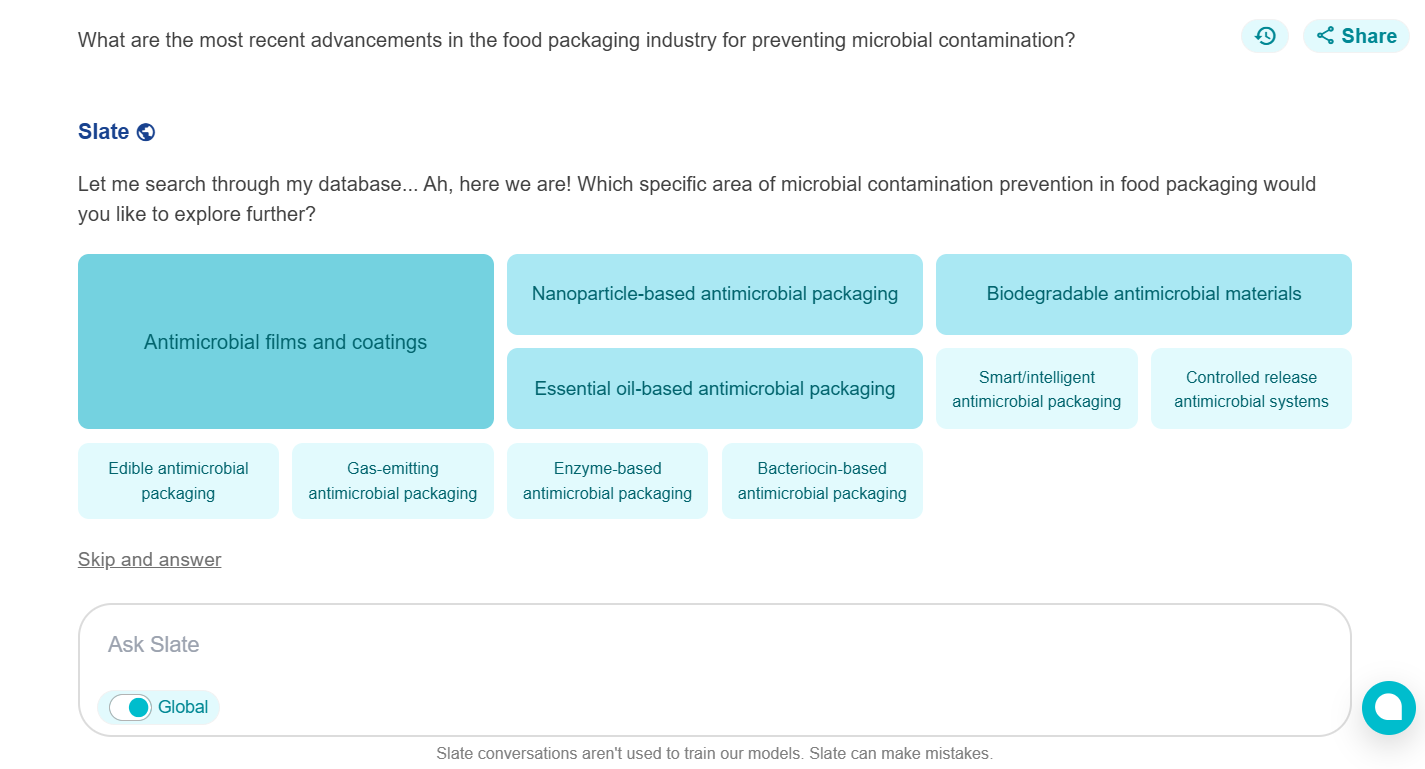

To maintain a competitive edge, it is essential to stay up-to-date with emerging technologies before they enter the market and become mainstream. However, with numerous ongoing research projects, it is nearly impossible for R&D heads to keep track. This is where Slate comes in. Just ask the AI assistant, “What are the most recent advancements in the food packaging industry for preventing microbial contamination?”; it’ll give you the latest innovations to track, compare, and adopt.

hbspt.forms.create({

portalId: “1791848”,

formId: “52650ba3-fcc1-4476-b4f7-6954e460ae4a”

});

DMK’s Low-Germ Packaging For Extended Shelf Life of Vegan Cheese

Unlike regular cheese, vegan cheese doesn’t have natural bacteria to protect it. That makes it more likely to be spoiled by germs during packaging.

DMK Deutsches Milchkontor has solved this industry challenge with its aseptic hot packaging method for vegan cheese. First, vegan cheese is prepared in a heated buffer container, maintaining a temperature that keeps the cheese in a liquid state. Keeping the cheese hot during filling and sealing it immediately helps prevent bacterial growth. Then, the sterilized liquid cheese is sealed in a multi-layer laminate bag made of linear low-density Polyethylene (LLDPE). Finally, the filled bag is cooled down, allowing the cheese to harden into a rectangular block—perfect for stacking or cutting. This results in minimal bacterial presence, improved shelf stability, and a longer freshness period for vegan cheese.

Recommended Read: Your Milk Carton Isn’t as Green as It Seems—But These Emerging Innovations Are Fixing That!

Conclusion

Beef and cocoa are expected to lead food recalls in Q2 2025, with projected increases of 163% and 162%, respectively. To effectively prevent food recalls, R&D and innovation teams in these segments must adopt a proactive approach to quality control, traceability, and risk management. This means rigorously assessing production processes, supplier reliability, and packaging materials before issues arise.

GreyB can help you build a recall-resilient innovation pipeline by:

- Identifying the latest trends and detailed data on food recalls

- Discovering practical technological solutions or startups to mitigate food recall risks

- Vetting these solutions to ensure their innovations are technically viable, scalable, and market-ready

- Assessing intellectual property landscapes to navigate licensing risks and secure strong partnerships

Fill out the form below to connect with our experts and start building a safer, more resilient food innovation pipeline today.

Talk To Our Experts Today

We support industry-leading R&D and Innovation professionals through complex problems. Describe your challenge, and let us bring clarity and expertise.