Around 75% of consumers seek snacks for their functional benefits, such as boosting energy, improving mood, and supporting fitness or diet goals. Yet, healthier cereal-based snack innovations often create new problems.

For instance, reducing sugar, adding fiber, or removing gluten makes snacks dry, brittle, or less flavorful. This turns away 74% of consumers who snack for taste and enjoyment.

Similarly, making cereal snacks sweeter, softer, and more indulgent creates a challenge in catering to allergy-conscious consumers who require clean labels, gluten-free options, and minimal additives. Balancing taste, nutrition, and safety simultaneously is a technically challenging task.

Present cereal-based snack innovations, such as the addition of hydrocolloids, modified starches, or commercial probiotic strains, do not resolve the industry’s complex balancing act. This growing tension is precisely where a new wave of startups is stepping in to reengineer cereal-based snacks.

This article mentions five such startups that are using technologies like precision milling and encapsulation to change the snack industry. It highlights how these startups are solving industry problems in innovative and effective ways with their patented technologies and formulations.

Industry leaders, including Cargill, Mars Snacking, and The Hershey Company, have also invested in these startups. Some of these are in the early stages of developing their cereal-based snack innovations. Partnering with, acquiring, or investing in these startups can give food giants a competitive edge in the industry.

Want to know which new startups are changing the food industry with innovations and how? Fill out the form and get your copy of GreyB’s exclusive report on food tech startups before your competitor knows about them.

1. A peanut-free PB&J that mimics the taste and texture of the traditional one

Rising risk of peanut allergies and food safety challenges

Peanut allergy is the second most common food allergy, affecting about 2% of the population, especially children, in Western countries. Studies show that 7% to 14% of people with peanut allergies experience accidental exposure each year, with one-third to half facing severe reactions like anaphylaxis.

Among the reasons for these unintentional exposures, processed food, peanut butter, and chocolates are the top three. Moreover, inconsistent food labeling and weak safety measures in restaurants and schools also contribute to increasing PA incidents. A FARE (Food Allergy Research & Education) study shows that over 25% of children with food allergies experience allergic reactions at school. As a result, parents are increasingly looking for snack options that are safe, easy to pack, and allergen-free.

Peanuts are also at risk because of climate change. Extreme heat is expected to reduce peanut harvests by 16–20% by 2050, threatening food supplies.

These factors create an opportunity for food companies to introduce peanut-free, clean-label snacks that are safe, delicious, and easy to carry.

Rudi’s and Voyage Foods’s peanut-free snack solution

Recognizing this opportunity, Rudi’s Rocky Mountain Bakery launched Sandos — a portable PB&J-style sandwich made with gluten-free, organic bread and clean-label ingredients.

Source: Rudi’s Bakery

The company collaborated with Voyage Foods, a food technology startup redefining allergen-free alternatives, to make their sandos peanut-free. Voyage Foods developed a roasted seed blend spread, made from sunflower kernels, grape seeds, chickpea flour, and rice protein.

Since its founding in 2021, Voyage Foods has rapidly gained industry recognition. Its innovations, such as peanut-free spread and cocoa-free chocolates, earned it a Fast Company 2024 World Changing Ideas Award in the food category.

Strategic collaboration and scaling efforts

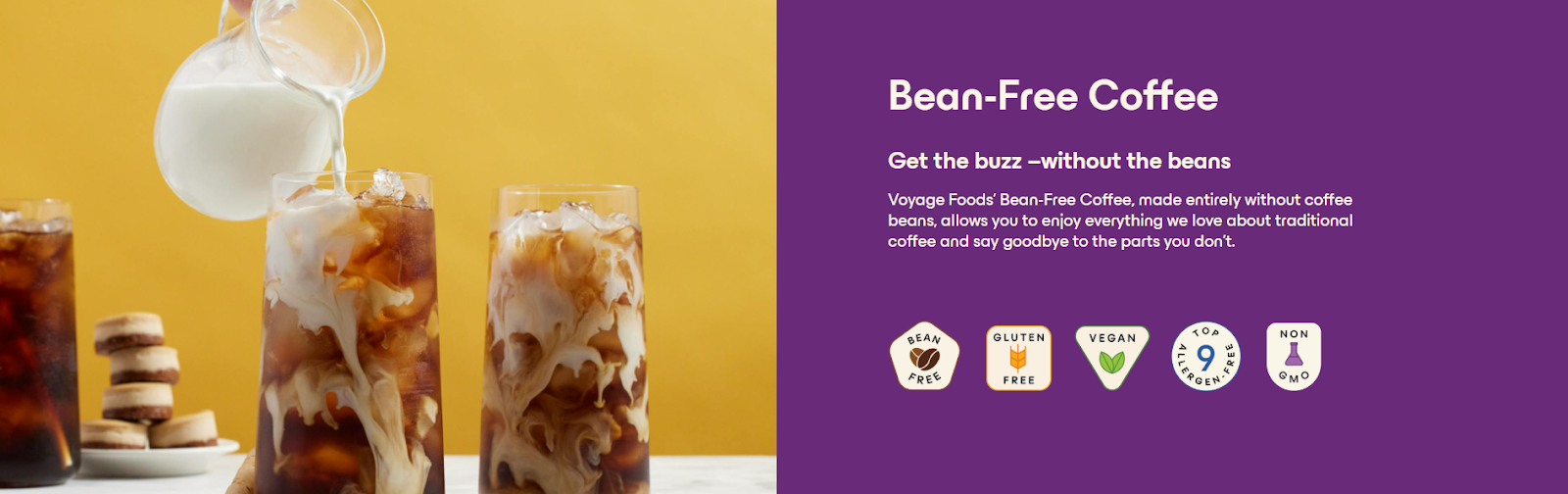

The startup’s products are already available at 1,400 retail locations nationwide, including Walmart stores, and monthly sales are steadily increasing. In April 2024, Voyage Foods announced an exclusive B2B partnership with Cargill to scale and distribute its cocoa-free and nut-free alternatives globally.

Source: Voyage Foods

After this partnership, it also secured $52 million in funding from investors. Voyage Foods is using this funding to transition from a startup to a scale-up. Next month, it will open a nearly 300,000 square-foot manufacturing facility in Ohio to increase its production capacity from metric tons per day to metric tons per hour. This will help the startup meet growing customer demand and enable national and global expansion of its cocoa-free chocolates, nut-free spreads, fillings, and bean-free coffee products. This increased demand shows that Voyage Foods’ products are meeting consumer expectations.

Source: Voyage Foods

The startup is able to meet consumer expectations due to its rigorous product testing approach. It conducts formal, large-scale sensory testing panels alongside a more agile, frequent testing program called “Project Compass. ” This program gathers fast, directional consumer feedback through smaller-scale sessions at local college campuses. This approach allows Voyage Foods to refine products rapidly based on live consumer data.

Voyage Foods was also selected by Mars Snacking and Unreasonable Group for its Unreasonable Food™ Year 1 Venture Cohort. The fifteen food space startups chosen in this Cohort have rapid growth potential and are rigorously tested. They are evaluated on factors such as problem statement and solution mindset, technology readiness and differentiation, funding, traction, potential impact, scalability, and timeline to partner. Being selected for this cohort demonstrates the industry impact, scalability potential, and production efficiency of Voyage Foods.

Read more about Voyage Foods and Similar Startups here

2. Frictionless milling that does not alter the nutrition and flavour of cereals

Challenges with traditional cereal milling methods

Traditional cereal milling methods, such as stone grinding, create excessive heat and shearing that damage the grain’s natural structure. This process destroys many surface cells and reduces the flour’s flavor and nutritional value. Conventional milling also separates starch from the germ and bran, losing important bioactive compounds like polyphenols.

As more people want healthier, less processed cereal snacks, there is a clear need for improved grain processing methods.

Innovative milling technology by Pain Cadet

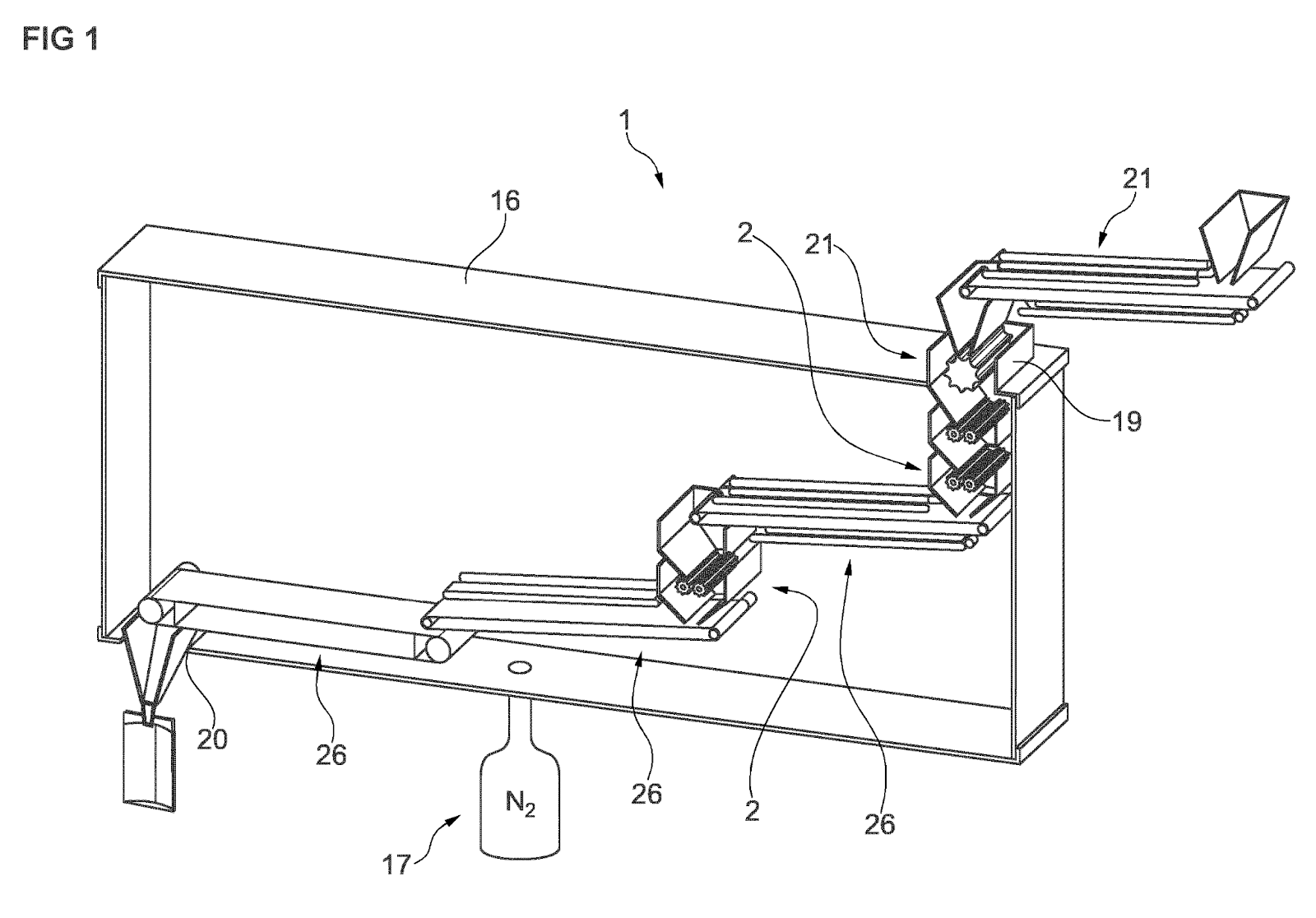

To address these challenges, Eric Favre, the former CEO of Nespresso and inventor of the coffee capsule, created a new patented innovation. This new machine uses comb rollers with adjustable gaps and interlocking teeth to gently break grains apart with minimal friction and heat. The rollers operate at different speeds and feature tapered, rounded teeth that further reduce mechanical stress.

To enhance nutrient preservation, milling can be conducted in an inert gas environment, such as nitrogen, which prevents oxidation and helps retain the grain’s complete cellular integrity.

Source: Patent

This approach directly tackles traditional milling’s core weaknesses by:

- preserving flavor

- extending shelf life naturally

- maintaining a more complete nutritional profile.

Eric launched Pain Cadet in November 2022, a startup specializing in processing equipment and products like bread. Under this venture, he created a crumbling mill, “Moulin-Émietteur,” focusing on scalability. Its current model can process 100 kilograms per hour, or approximately 16 tonnes per month across 20 production days.

By preserving the natural properties of grains, Pain Cadet’s milling innovation enables cereal-based snack producers to achieve cleaner labels, better-tasting products, and sustainable processing.

Food Tech Trends Report

Download The Report3. Gluten-free cereal that doesn’t taste like cardboard

Gluten risks and compromised flour quality

Gluten proteins are a persistent risk for people with celiac disease. During digestion, gluten breaks down into Gluten Immunogenic Peptides (GIPs), which can trigger immune responses and cause intestinal damage.

Alarmingly, trace amounts of GIPs can even be found in some gluten-free diets, leading to unintended exposure. Meanwhile, most gluten-free flours do not match the texture, elasticity, and flavor that consumers expect, making them less desirable for broader snacking applications. This is because conventional methods that effectively reduce gluten often compromise flour quality. For example, enzymatic hydrolysis using proteases like papain or trypsin can partially break gluten proteins. However, it often leaves behind immunogenic peptides, such as the 33-mer from gliadin, which still trigger immune responses. Similarly, heat treatments can denature proteins but do not break peptide bonds and cause protein aggregation.

Chemical methods using reducing agents such as dithiothreitol (DTT) disrupt disulfide bonds and weaken gluten’s structure. However, they introduce off-flavors or raise safety concerns, limiting their use in food products.

Most conventional methods fail to fully degrade gluten while preserving the familiar sensory profile of wheat-based flours.

Bread Free’s ultrasonic and enzyme technology

Bread Free, a Spanish biotech startup, is changing that. The company has developed a proprietary gluten-free cereal flour by combining ultrasonic treatment and enzyme incubation. Ultrasonic treatment gently disrupts gluten structures without damaging the flour’s natural texture. On the other hand, the targeted enzymes break down gluten proteins into smaller fragments and amino acids, thereby reducing the presence of GIPs.

The startup process consistently achieves gluten levels below 20 parts per million (ppm). It often reaches ≤10 ppm, only seen in specialized gluten-free flours, while retaining the texture, flavour, and nutritional quality of traditional flours. Recognized for its innovation, Bread Free has won the Foodtech Innovations and Ingenia Startup Awards. It has patented the flour development process that can be used to produce gluten-free wheat, barley, and rye flours.

Source: Bread Free

Bread Free opened its production facility at the Agro-Food City of Tudela and began commercial-scale manufacturing in September 2024. Its gluten-free flour brand, PURA, is currently produced at a capacity of 3 tons per month, with plans underway to expand to 30 tons per month.

Recommended Read

Collaboration and scaling

Bread Free recently signed a distribution agreement with Foody, a Madrid-based brand specializing in allergy-friendly foods, to bring its flours to bakeries, pastry shops, and food companies across Spain. Artisan bakeries like Con un poco de azúcar in Zaragoza have already incorporated Bread Free’s flour into their offerings. The startup recently collaborated with Exento Sin Gluten, a bakery in Madrid, to expand its PURA products range.

The startup is supported by innovation and investment players, including the European Business and Innovation Centre of Navarre (CEIN), FOOD+i Food Cluster, CDTI, CaixaBank DayOne, and the Government of Navarre.

Beyond improving health outcomes, its process is environmentally friendly. The startup claims it sources ingredients from agri-food by-products and does not require added sugars and fats to mimic texture and taste. This promotes the circular economy and reduces manufacturing costs.

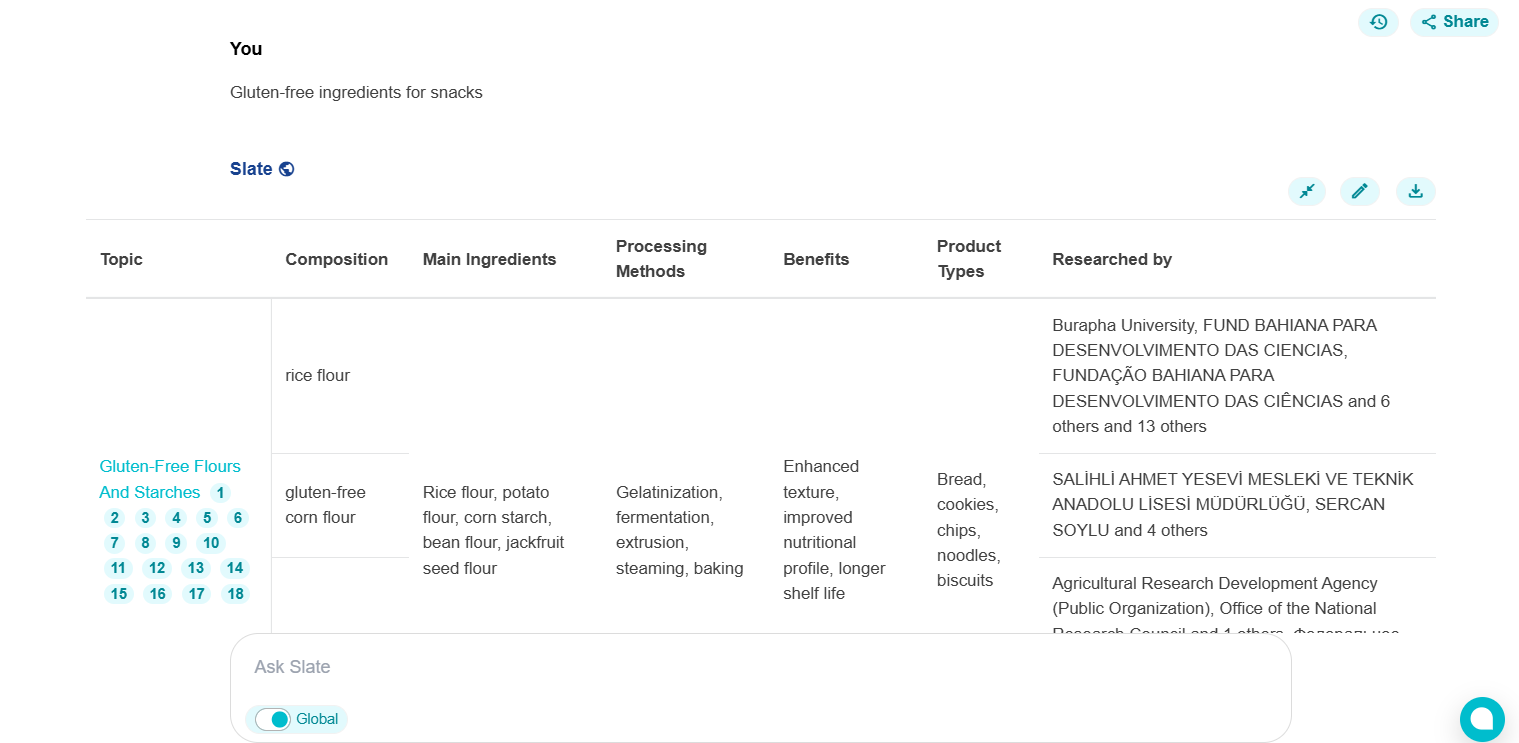

Finding these emerging innovations using standard tools like Google search is time-consuming. You’ll have to sift through hundreds of search results, many irrelevant to your search intent. This is where a technology scouting tool like Slate helps out.

All it needs is a simple query, like “Gluten-free ingredients for the food industry.”

Within minutes, Slate scours through hundreds of patents and research papers, finds highly relevant inventions, and presents them in a neat dashboard. Here’s a screenshot as an example:

4. An imitation flour that cuts carbs by 80% while preserving the texture and stretch of traditional flour

Need for low-carb flours that don’t compromise taste or texture

Many people, especially those managing diabetes, obesity, or other metabolic disorders, are unable to consume traditional cereals or potatoes due to their high carbohydrate content. While low-carbohydrate flour substitutes like coconut or almond flour exist, they often fail to replicate the familiar taste, texture, and cooking performance of conventional flours. These qualities are essential for products such as pasta, bread, and baked snacks, where starch gelatinization determines the desired texture.

Locawo’s resistant starch flour

Recognizing this gap, German startup Locawo—short for “Low Carb Wonder”—has developed an innovative line of imitation cereal, potato, and rice flour. These flours contain up to 80% lower digestible carbohydrates and 60% more dietary fiber than traditional flours while closely matching the taste, texture, and functional properties consumers expect.

Locawo’s approach relies on RS4 resistant wheat starch, a specialized form of starch engineered to remain undigested in the small intestine and function as dietary fiber. This effectively reduces the flour’s glycemic impact without compromising its baking performance. Locawo’s formulation also retains comparable protein and fiber levels to traditional wheat flour, ensuring strong structural performance in finished products.

Founder’s vision and product availability

The startup’s product range includes all-purpose flour, cake flour, and specialized blends for bread, pizza, and pasta. These flours can be used as a 1:1 replacement for conventional wheat flour, making adoption easy for both home bakers and commercial producers.

Additionally, Locawo offers ready-to-eat baked goods, including breads, rolls, and pastries, catering to the growing demand for convenient, health-conscious options. The startup’s products are produced in Artlenburg, Germany, and are currently available for delivery across Germany and Austria.

Founded by master baker Thomas Wiechel, who personally experienced the challenges of adhering to a low-carb diet, Locawo combines culinary expertise with nutritional science. Reflecting this personal innovation journey, the patent for Locawo’s technology was filed under Wiechel’s name.

5. Probiotics that survive the shelf, oven, and stomach- from cereal bars to baked goods

Problems in delivering probiotics in food

Delivering probiotics through food products remains a major challenge for manufacturers. During processing, storage, cooking, and even digestion, probiotics are highly susceptible to environmental factors such as heat, moisture, oxygen, and light, and can become lost. These factors impact the viability of probiotics in foods.

To compensate for these losses, food companies add excess probiotics to products to meet dietary standards — an inefficient and costly approach.

Vitakey’s advanced encapsulation technology for probiotic protection

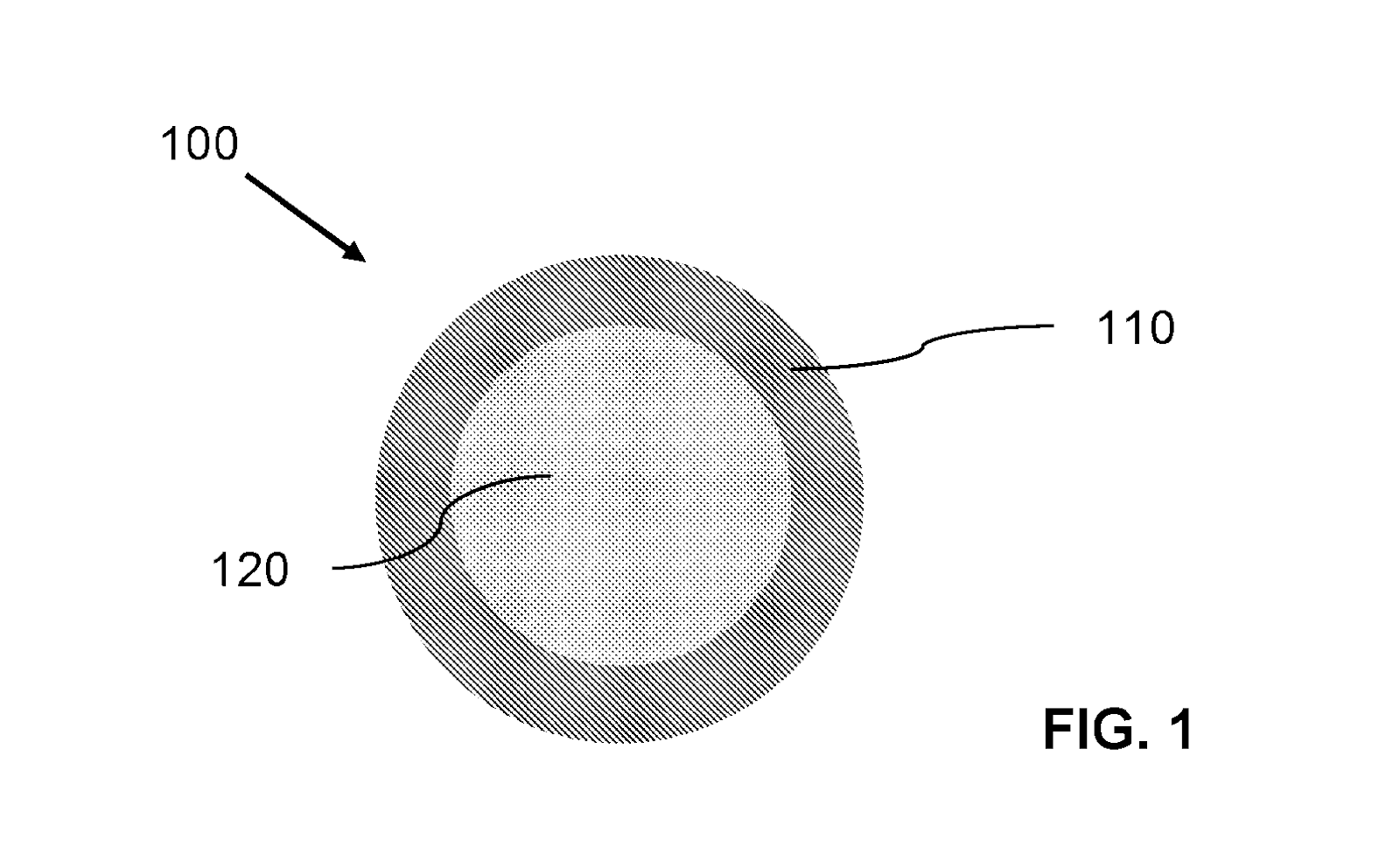

VitaKey Inc., a U.S.-based startup founded in 2020, has developed a patented probiotic encapsulation technology to address this issue. Leveraging research from the renowned Langer Lab at MIT, led by Dr. Robert Langer — a pioneer in drug delivery and controlled-release systems — VitaKey’s solution brings pharmaceutical-grade precision to functional food development.

VitaKey’s technology encapsulates probiotics within hydrophobic or lipid-based coatings, enhancing their stability, shelf life, and compatibility with a wide range of food matrices.

To further protect the probiotics during digestion, paired layers of biodegradable polysaccharides such as chitosan and alginate shield the bacteria from stomach acids and bile salts. This advanced coating system also enables the probiotics to adhere to the intestinal mucosa, promoting prolonged colonization and maximizing health benefits.

Source: Patent

This breakthrough allows probiotics to remain largely viable even in challenging applications such as bread, rice, and cereal-based snacks — categories where maintaining live cultures has traditionally been difficult.

Beyond probiotics, VitaKey’s technology enables targeted and time-controlled release of a wide range of sensitive nutrients — including micronutrients, vitamins, nutraceuticals, antioxidants, proteins, amino acids, and flavors — with excellent bioavailability. Their encapsulation systems can be triggered by specific pH levels or environmental stimuli, ensuring nutrients are delivered exactly when and where they are most effective.

Additionally, VitaKey’s method can enhance desired flavors and aromas while masking unpleasant tastes and odors, expanding its potential across customized diets, infant and elderly nutrition, pet food, seeds and agriculture, and broader food and beverage innovation.

Strategic collaboration with Hershey

Signaling the growing industry relevance of precision nutrient delivery, Hershey Co. announced a strategic partnership with VitaKey in February 2025 to develop a new suite of health and wellness food products. While specific product details and launch timelines have not yet been disclosed, Hershey’s CEO Michele Buck highlighted the move as part of Hershey’s broader strategy to address distinct health and wellness needs across protein snacking, sugar-free products, and enhanced macros.

Probiotic Research Trends Report

Download The ReportConclusion

Startups and innovations, such as those listed above, in the cereal-based snack industry are closing the gap between taste, health, and safety. Food companies must stay informed about such innovative startups to drive breakthrough solutions that address evolving consumer demands for healthier, sustainable, and functional snacks.

Moreover, keeping track of these innovations will help companies identify new ingredients, production methods, and technologies to differentiate their products, meet dietary trends, and maintain competitiveness.

However, obtaining this information is challenging due to the sheer volume of startups, the rapid pace of technological advancements, and the difficulty in scaling innovative solutions.

Additionally, navigating the complex regulatory landscape and identifying scalable, cost-effective technologies can make it hard for R&D teams to filter the most relevant and viable innovations for their needs.

This is where GreyB steps in, helping you navigate these complexities with ease.

Whether you’re looking to explore new ingredients, refine your production processes, or stay compliant with evolving regulations, our experts can help you find:

- The current trends in the snack/food industry

- Which of your competitors is investing in which innovation and startup

- How scalable and easy is it to implement the innovation?

Ask your query using the form below, and our research experts will get in touch with you.

Get In touch with our experts

Fill out the form to know more about food industry innovations and trends