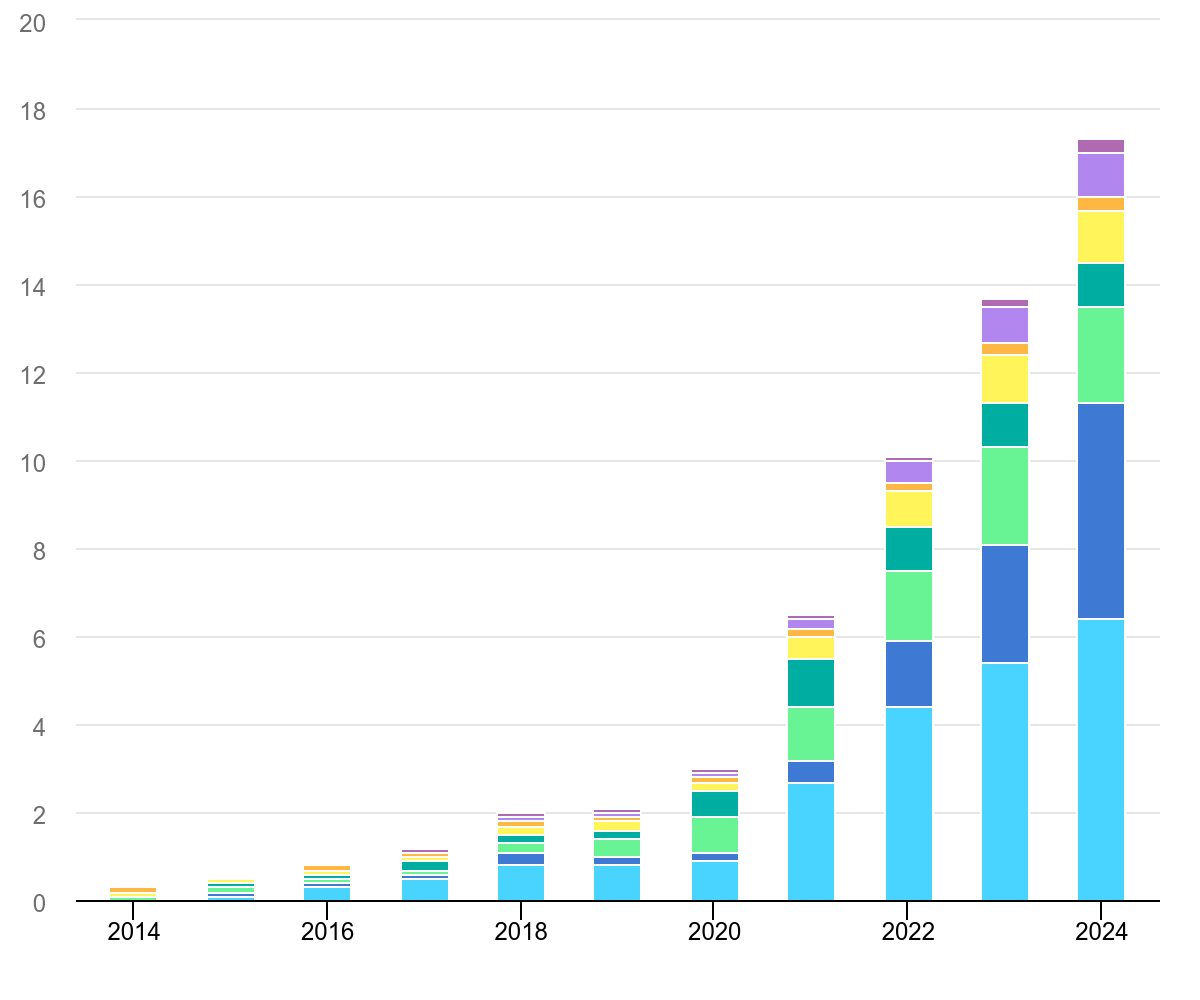

Global sales of electric vehicles reached a record 17 million units in 2024, up approximately 25% year-over-year, and have continued to grow strongly into 2025, with a 29% increase in Q1 alone.

Despite this momentum, challenges like range limits, charging safety, infrastructure complexity, and thermal risks remain hurdles to broader adoption.

To solve this, leading automakers are driving breakthroughs in battery technology, charging systems, and safety materials. This article examines five key trends by these companies reshaping EV innovation:

- Solid-State Batteries – enabling greater energy density and faster charging for extended range.

- Dynamic (On‑the‑Move) Charging – reducing stops and boosting convenience.

- Smart Charging Station Recommendations – optimizing user experience and environmental impact.

- Advanced Battery Management Solutions (BMS) – for real-time health monitoring and safety.

- Fire‑Resistant Composites for Battery Housings – mitigating overheating and thermal runaway risks.

For each trend, its current state, technical challenges, and emerging solutions are provided.

We’re compiling a comprehensive report on these EV innovations and related trends. Fill out the form below, and you’ll be among the first to get a PDF of those insights directly in your inbox.

1. Dynamic Wireless Charging

Slow charging EV stations and range anxiety led companies to explore electrified roads that charge vehicles while in motion. This concept, called in-motion or dynamic wireless charging, aims to reduce downtime and increase convenience.

Companies like Electreon Wireless are testing this technology across Europe, Asia, and the United States, with pilot projects underway in cities such as Detroit, Tel Aviv, and Trondheim. These trials focus on passenger and commercial vehicles, exploring real-world applications of dynamic wireless charging.

However, challenges like uneven roads and power loss during charging make adapting this technology difficult. Additionally, road integration for wireless charging presents challenges, including vehicle misalignment and electromagnetic interference.

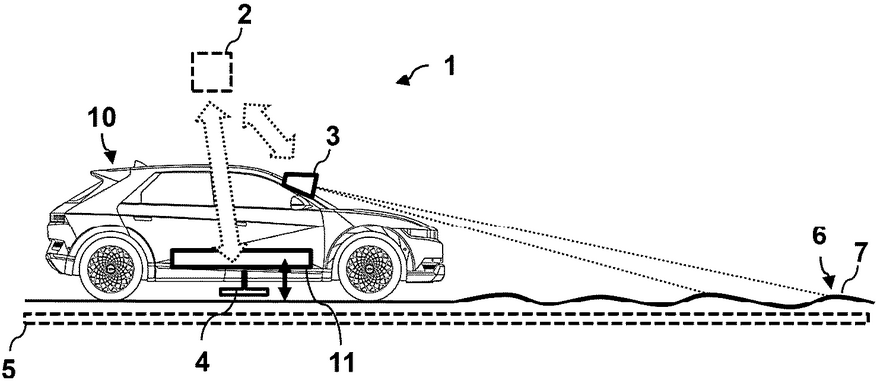

Potholes are no longer a problem in wireless charging

To address this, Hyundai developed a system (controller) that monitors road conditions in real-time using sensors such as cameras and LiDARs, as well as data shared by other vehicles and navigation systems. Using this data, the system dynamically adjusts the vehicle’s driving route, lane position, and the height of the inductive charging coil to maintain optimal alignment with the road-embedded charging infrastructure.

This approach maximizes charging efficiency by selecting the flattest possible route segments and minimizing the need for frequent adjustments. At the same time, it protects the vehicle from damage caused by rough or uneven road surfaces by maintaining a safe but close distance between the charging coil and the road.

Source: Patent

Hitachi also filed a patent for something similar to Hyundai’s alignment system.

Hitachi’s unique innovation and its improvement of wireless charging are further discussed in our upcoming comprehensive report on emerging innovations and trends in EVs. The report also discusses exclusive insights into emerging innovations, trends, and patent intelligence of the EV industry. Moreover, it will include expert analysis on the scalability, impact, feasibility, and growth of the electric vehicle (EV) technologies included.

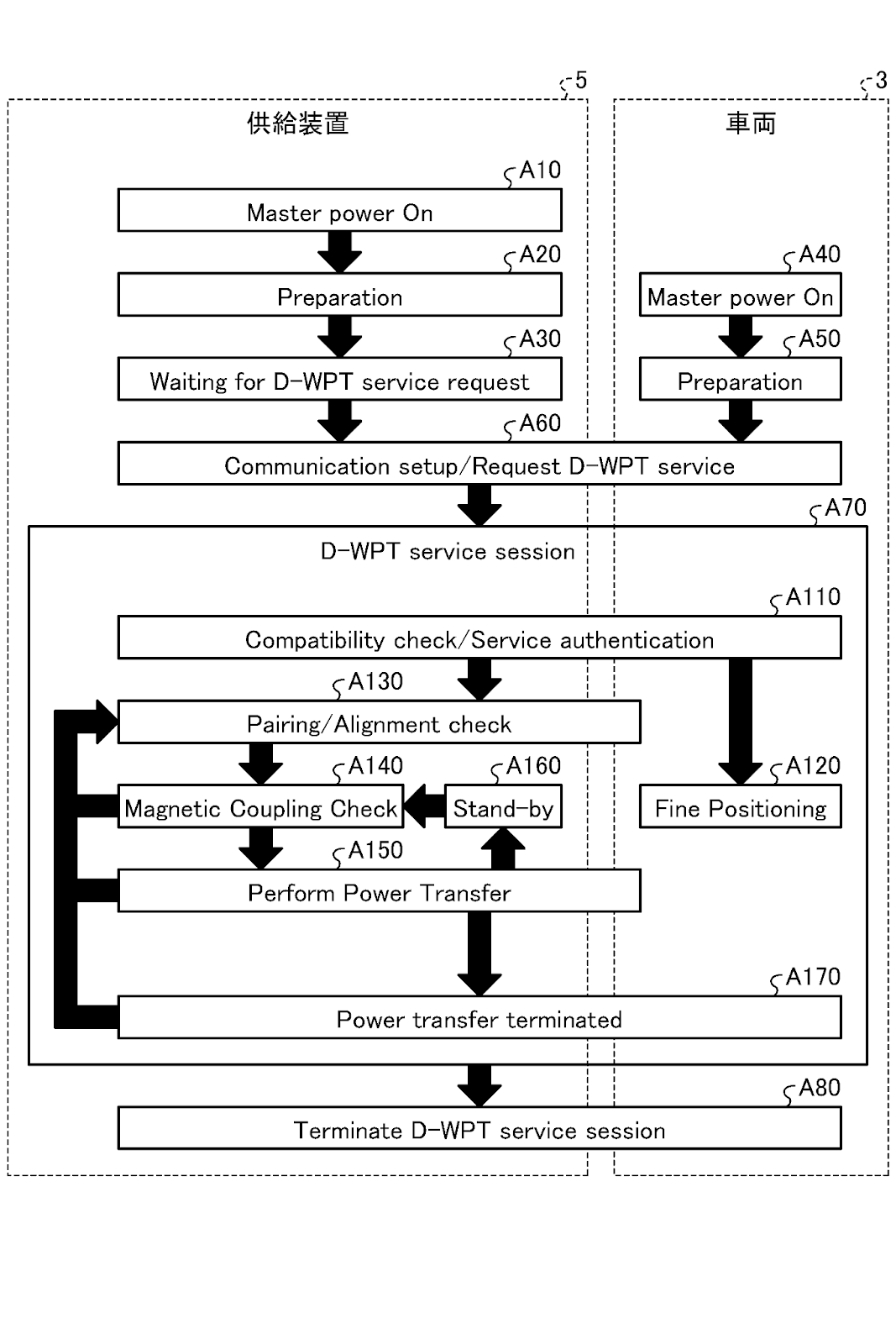

Reliable charging in-motion even after a power outage

When electric vehicles charge wirelessly while in motion, power outages or shutdowns on the roadside charger can suddenly interrupt the charging process. Until recently, there was no clear way to restart the charger safely after these outages. This caused safety risks and delays because the vehicle and charger might not sync up properly.

Toyota and Denso developed a contactless power supply system that solves the issue by adding two wireless communication devices into the roadside charger. One device is for long-range communication and one for short-range communication with the vehicles that are charging.

It also includes a system that detects faults, such as if the power cuts out or something goes wrong. When this happens, the charger stops sending power and then follows a set process to restart safely once power is stable again. This keeps the vehicle and charger connected, ensuring a smooth charging process.

By clarifying and automating the restart process after outages, the system enhances both operational safety and efficiency. It prevents unsafe power delivery scenarios, reduces the need for manual intervention, and ensures seamless resumption of wireless charging during vehicle motion.

2. Smart Charging Recommendation Systems

Smart charging solutions still face challenges, particularly during peak times when the increased demand for electricity strains the local grid. This can lead to grid instability, power outages, equipment malfunctions, and higher electricity costs. To address these issues, smart charging stations can slow or delay charging, often frustrating users due to longer wait times or incomplete charges.

To tackle this more effectively, personalized recommendations can be introduced, enabling the system to adjust charging schedules according to individual needs, like suggesting a delayed start for users with more flexible schedules. The system can ensure efficient charging without overloading the grid by understanding each user’s habits and preferences.

To overcome this dilemma, automotive giants such as Honda and Mercedes are developing solutions, including cloud-based systems. These innovations provide real-time, route-based, and grid-aware charging suggestions to enhance the efficiency, sustainability, and usability of electric vehicle charging.

EVs are planning their routes to increase efficiency with a smart charger search

Sumitomo and Honda have developed a charger search device to help electric vehicles find the most suitable charging stations along a planned route.

First, it identifies the EV’s route from point A to point B and breaks it into sections based on expected changes in driving speed, such as areas where the vehicle is likely to slow down or speed up.

For each section, the system estimates the vehicle’s speed and the amount of battery power it will consume during that section. It also checks the current battery level at the starting point and calculates the total power that will likely be consumed along the way.

If the vehicle doesn’t have enough battery to complete the journey, the system determines how much additional charge is needed. It also estimates the amount of energy that can be added to the battery at various locations along the route, taking into account available time and charging conditions.

Based on all this data, the system searches for charging stations that can deliver the necessary charge efficiently and within the expected time frame.

EV Charging Startups Report

Download The ReportPersonalized charging station recommendations for better charging efficiency

Electric vehicles are often charged at home, but long trips require stops at charging stations along highways. These stations differ in charging speed, quality, and amenities. Sometimes, the stations do not deliver the charging experience they advertise, or they may not be fully compatible with specific electric vehicle models.

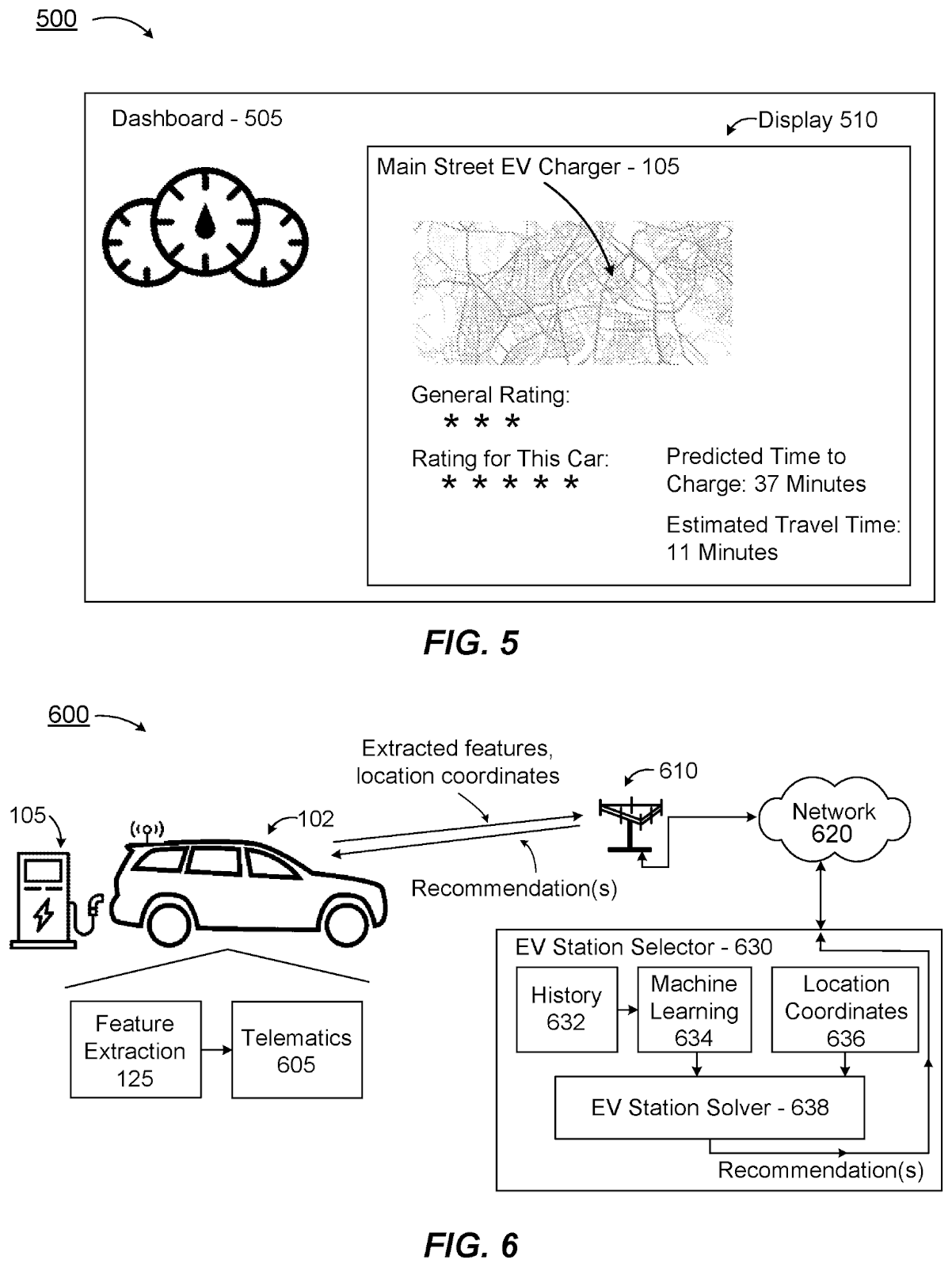

Mercedes-Benz is addressing this issue with a system for recommending the best charging station for an electric vehicle (EV) based on real-time data during the charging process.

When the EV begins charging at a station, the system monitors the electric current and voltage to detect any abnormalities or inefficiencies in the charging process. Using this data, the system evaluates the vehicle’s performance and creates a “charge performance model.” This model enables the system to recommend a more suitable charging station if the current one is not optimal, taking into account factors such as charging speed, battery stress, and vehicle compatibility. Additionally, the recommendation can include the estimated time to charge and the travel distance to the next station, ensuring the EV operator can make an informed decision while on the go.

What’s more interesting is that it collects and analyzes data from past charging sessions and provides feedback to future users.

For example, if certain vehicles experience thermal or electrical stress during charging at a particular station, this data can be used to inform subsequent users coming to that station. The system can recommend whether the charging station is suitable for the next vehicle based on its specific needs and charging history. This ensures that EV operators receive tailored recommendations for the best charging stations, potentially preventing issues like overcharging or excessive stress on the battery.

Source: Patent

Ford’s cloud-based system recommends charging stations based on Sustainability and Cost

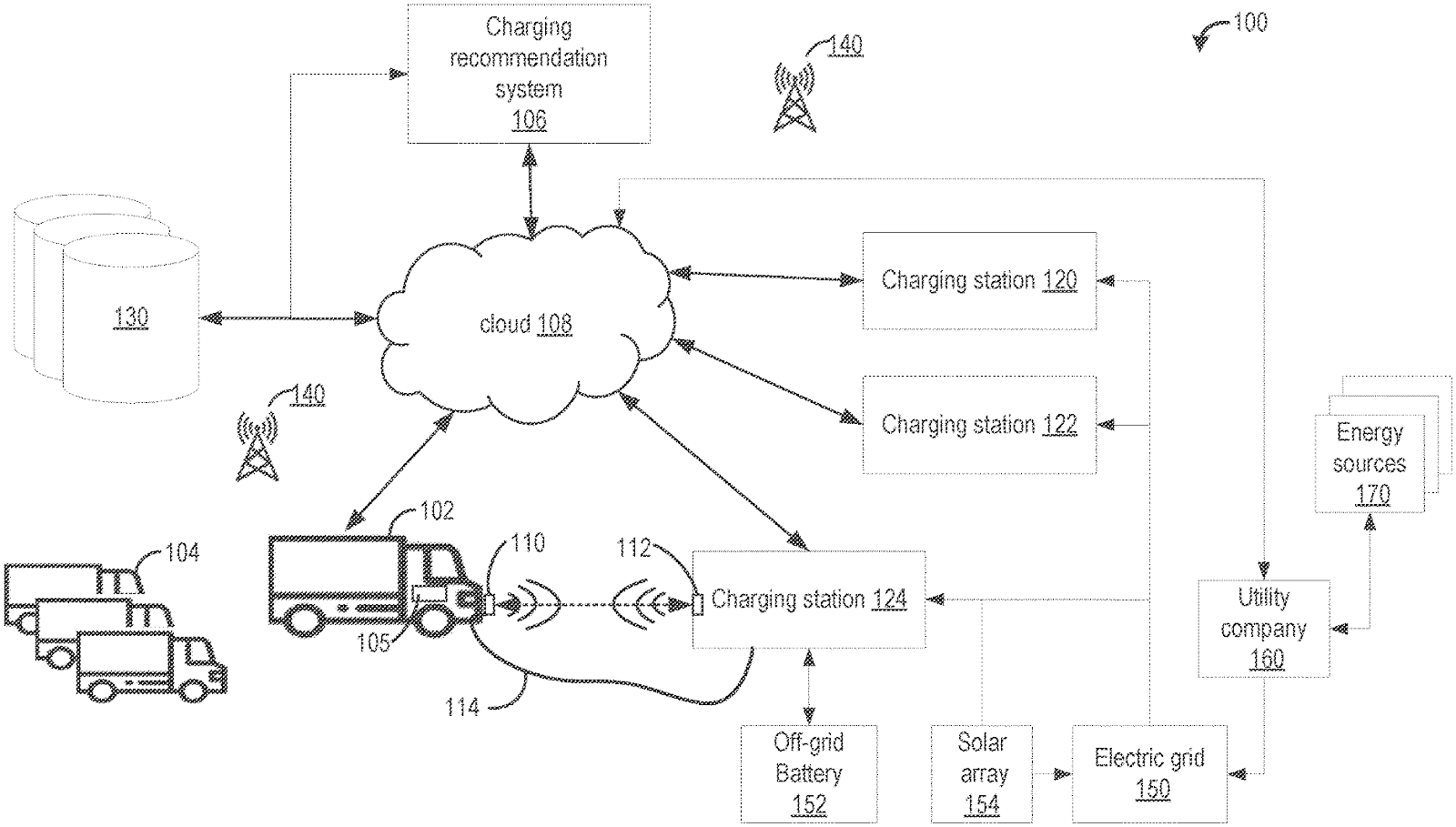

Electric vehicle charging stations draw electricity from the power grid or use off-grid sources like solar panels and batteries. The electricity itself can come from both renewable (e.g., wind, solar, hydro) and non-renewable sources (e.g., coal, gas), each with different environmental impacts such as carbon emissions, water use, and land footprint.

These environmental impacts vary by location, time of day, and season, depending on energy source mix and regional conditions. For example, sunny regions may rely more heavily on solar energy during the day, while fossil fuels may dominate at night or during periods of high demand. Regulatory agencies and users may prioritize different environmental factors—some focus on carbon emissions, while others may care more about water usage or local pollution.

Even if charging stations claim to provide 100% renewable energy via Renewable Energy Credits (RECs), this doesn’t always equate to zero emissions. The actual impact depends on timing, infrastructure, and energy sourcing. Charging options also differ by technology, including Level 2 chargers, fast chargers, battery swapping, and wireless systems, all of which have different impacts on infrastructure, energy efficiency, and vehicle travel. Hence, EV users lack tools to easily assess the most sustainable charging option.

To solve these issues, Ford created a cloud-based charging recommendation system. It sends personalized charging recommendations to electric vehicles (EVs), helping drivers choose stations and times that reduce environmental impact.

These suggestions are based on battery data and driver or owner preferences, sent securely from the EV. The system calculates environmental costs per kWh using data on charging infrastructure and energy sources. It ranks options that align with user priorities, such as minimizing the carbon footprint.

Unlike generic systems, this approach tailors recommendations using detailed vehicle and user input, guiding drivers toward more sustainable charging choices and increasing reliance on renewable energy during charge events.

Source: Patent

Hyundai and Myongji University created a similar end-to-end encrypted charging system. Read more about this in the complete version of this report. Secure your early access to this upcoming report by filling out this form.

Get the Report in your Inbox

Fill the form to get access to the report

3. Solid-State Batteries

Solid-state batteries are a popular choice among several major automakers for their EVs. For instance, Stellantis plans to launch a demonstration fleet of electric vehicles equipped with solid-state batteries from U.S. startup Factorial by 2026. Similarly, Toyota has announced intentions to commercialize solid-state batteries by 2027, aiming to enhance vehicle range and reduce charging times.

They offer higher energy storage, faster charging, improved safety, and longer lifespans compared to traditional lithium-ion batteries. Additionally, solid electrolytes are safer for the use of energy-dense materials.

However, managing the mechanical stress caused by the expansion and contraction of the battery electrodes during charging and discharging is a major challenge in these batteries.

This is especially true for materials like silicon and lithium metal, which expand and shrink significantly, leading to structural damage and shorter battery life.

Companies like Honda & Maxell, Hyundai, and Toyota have developed solutions to better control this expansion in their solid-state batteries.

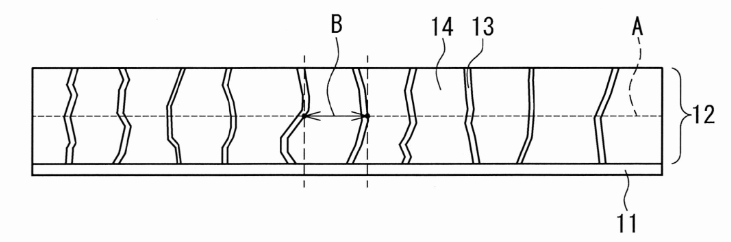

Columnar Electrode Structure for Improved Solid-State Battery Durability

Honda and Maxwell have introduced a new negative electrode design for solid-state batteries. It tackles the challenge of material expansion during charging and discharging in high-capacity batteries.

These batteries use materials like silicon (Si), tin (Sn), and aluminum (Al) in electrodes. These materials can store lithium more than traditional graphite, but expand and contract significantly during use, leading to cracking and reduced performance.

How it addresses expansion:

- Columnar Structure: During the first few charge-discharge cycles, the electrode naturally forms vertical cracks that divide it into columns. These columns allow the material to expand and contract without damaging the structure. This reduces internal stress, prevents cracks, and keeps a stable connection with the current collector.

- Material Selection: Using Si, Sn, or Al in a layered mix helps balance capacity and structural stability. The different materials spread out the stress, making the structure more durable.

- Manufacturing Advantage: This structure can be made using standard coating methods—no need for expensive techniques like vapor deposition. It is easier to scale for real-world use.

Source: Patent

This innovation combines a smart structural design with high-capacity materials, resulting in a battery that holds more energy and lasts longer. It is suited for electric vehicles and portable devices.

The comparative analysis conducted shows that Batteries produced according to this invention retained excellent cycle capacities. These batteries have demonstrated high initial capacity and maintained performance even after 300 charging/discharging cycles at 60°C.

In contrast, batteries without a solid electrolyte or appropriate binder failed to form the necessary stable columnar structure in the negative electrode layer. This resulted in substantially reduced initial capacities and complete capacity failure by the 300th cycle.

Similarly, the battery with a non-rubber binder initially displayed high capacity but suffered significant capacity loss upon cycling due to the absence of a columnar structure.

EV Battery Startups Report

Download The ReportAnode-Free Configuration to Minimize Volume Change

Hyundai has developed an anode-free solid-state battery that helps solve the battery design problem of volume changes during charging and discharging. In most batteries, the anode expands and contracts as lithium moves in and out, which can lead to damage over time.

To fix this, Hyundai replaced the traditional anode in a battery with a bare current collector.

How does it reduce expansion:

- Anode-Free Structure: Without a regular anode, lithium is deposited directly onto the current collector during charging. This avoids the swelling that usually happens in standard anode materials.

- Buffer Layer: A buffer layer helps manage lithium buildup, reducing stress and stabilizing the structure.

- Alloying Intermediate Layer: The collector includes a layer made from materials that form a smooth bond with lithium. This helps control lithium growth and prevents sudden volume changes.

Tests illustrate that traditional batteries without a buffer layer showed a thickness change of approximately 12 μm during charging and 7 μm during discharging.

In contrast, Hyundai’s battery experiences thickness changes of only about 1 μm or less, representing a volume change of under 1%, and even as low as 0.2%.

This innovation offers a safer, longer-lasting, and more reliable battery for electric vehicles where space efficiency and durability matter most.

Electrodes that handle expansion stress better for longer EV battery life

Silicon is widely used in battery anodes for its high lithium storage capacity. However, it expands and contracts significantly during charging, which can lead to cracking and reduced battery life. To address this, Toyota has developed a composite electrode material that combines silicon particles with fibrous conductive materials, such as fibrous carbon, to handle expansion stress better.

How it addresses the expansion problem:

- The material comprises silicon particles embedded with fibrous carbon. Instead of relying on a single, dense silicon block, the structure distributes lithium storage across smaller particles. This helps reduce the impact of expansion during charging.

- The fibrous carbon is localized inside each composite particle, acting as an internal support system. It absorbs and distributes stress as the silicon expands, maintaining the particle’s shape and preventing cracks.

- Spray-Drying Manufacturing: Toyota uses a spray-drying method to create these particles. This technique enables precise control over particle size and material distribution, resulting in more consistent performance across the entire electrode.

Comparative testing reveals that traditional silicon electrodes without fibrous conductive materials have a baseline relative expansion (restraining pressure increase) of 1.00. Introducing particulate conductive materials improved this slightly to 0.93. Additionally, using fibrous carbon materials significantly enhanced stability, specifically fibers with a diameter of 150 nm (VGCF), which reduced expansion to 0.87. Furthermore, thinner fibers (carbon nanotubes, 10 nm diameter) achieved even greater improvements, decreasing expansion substantially to 0.68.

Overall, this design enables the battery to maintain high capacity while reducing damage from repeated charge-discharge cycles. The result is a more durable, stable solid-state battery that is well-suited for electric vehicles where long life and safety are critical.

These emerging innovations solve key challenges, including charging time, battery safety, and range anxiety, that have slowed EV adoption.

Getting early access and adapting to these emerging innovations is crucial for automotive companies to gain a competitive edge, especially this year, when the EV segment is expected to grow by 17%.

However, with loads of ongoing research, it is nearly impossible for R&D heads to keep track of these innovations. This is where Slate by GreyB comes in.

Just ask the AI assistant, “What are the emerging innovations in the electronic vehicles industry?” It will give you the latest innovations to track, compare, and adapt.

Source: Slate Dashboard

4. Advanced Battery Management Solutions (BMS)

As one of the most expensive components of EVs, batteries face challenges such as degradation over time, limited charging infrastructure, and varying environmental conditions.

Addressing these challenges requires advancements in battery diagnostics, charging management, and predictive analytics.

The next section of this article discusses a few such technologies that demonstrate how companies are addressing these challenges through sophisticated battery management systems.

Recommended EV Industry Read

Stress deformation monitoring for real-time battery health

Monitoring stress within battery cells is crucial to enhancing the safety and reliability of electric vehicles (EVs) and energy storage systems.

Huawei’s solution uses stress sensors placed on the explosion-proof valve of each cell to detect pressure changes in real time, helping identify faulty or high-risk cells before they fail. This invention addresses a significant gap in the existing diagnostic systems.

This system uses small sensors placed on or near the battery’s safety valve. These sensors monitor for signs of stress within the battery, such as swelling or overheating, which can lead to failure or fire.

The sensors send signals to a processor that determines the location and severity of the issue. This helps detect problems early, allowing for quick action to prevent damage.

The system is compact, easy to install in existing electric vehicle batteries, and doesn’t require bulky testing tools. Multiple sensors can be added across the battery for better monitoring and easier upkeep.

LG has developed a diagnostic technology that can individually evaluate the condition of multiple active materials within a battery electrode during both manufacturing and usage. This precise analysis helps ensure batteries are made according to design and continue to perform efficiently over time. Learn more about this innovation and its impact on improved battery management in our full report on emerging EV innovations and trends.

While we are compiling this EV innovations and trends report, you can download this EV research report to get an overview of ongoing research and industry growth:

AI-powered Remaining Useful Life prediction to increase the longevity of EV batteries

Accurately predicting the remaining useful life (RUL) of electric vehicle (EV) batteries is crucial for enhancing safety, performance, and effective maintenance planning.

To achieve this, S&S Co., Ltd., in collaboration with Chungnam National University, has developed an AI-powered method that uses real-world driving data and context-aware labeling to improve RUL predictions.

Unlike traditional methods that rely solely on battery resistance, this system considers how the battery is used and the conditions it encounters.

This system helps predict the lifespan of an electric vehicle battery by utilizing smart data and AI.

It first collects key battery health data—such as charge level, resistance, and the rate of charging or usage—and labels it based on how the car is driven, who uses it, and the prevailing climate.

Then, an AI model uses this labeled data to give more accurate, real-time estimates of battery life.

The system adjusts its predictions by factoring in real-world conditions, such as driving habits, weather, and whether the vehicle is privately owned or used for purposes like rentals or public transportation.

It can run either in the vehicle or in the cloud, and keeps the data secure using technologies like blockchain.

This innovation enables better decision-making for battery replacement and maintenance, resulting in longer-lasting batteries and a more reliable electric vehicle (EV) experience.

Digital twin models for accurate battery health tracking

Eatron Technologies’ digital twin system enhances the accuracy of electric vehicle (EV) battery health tracking by integrating real-world usage, laboratory data, and manufacturer specifications. It estimates the battery’s State of Health (SoH) in real time and adds a confidence score to show how trustworthy each estimate is.

How it helps improve battery efficiency and safety:

- Real-Time SoH Updates: Tracks battery use during driving and charging to provide accurate, up-to-date health estimates, enabling smarter energy use.

- Rich Data Integration: Combines test data, battery specs, and usage history to get a complete picture of battery aging.

- Confidence Scores: Inform users about the reliability of the health estimate, based on usage patterns such as rest periods and charging behavior.

This enhances battery monitoring, making it more precise, transparent, and valuable for improved safety, maintenance, and long-term performance.

5. Fireproof Batteries

Fire hazards associated with lithium-ion batteries have become a significant safety concern for electric vehicles (EVs). Thermal runaway, caused by overheating, mechanical damage, or electrical abuse, can lead to fires and considerable property damage.

Traditional solutions, such as water-based fire suppression, are insufficient for high-capacity electric vehicle batteries, where thermal runaway in one cell can quickly spread to others. Recognizing this, several companies are developing novel technologies to tackle these risks.

One such startup is Elven Technologies, which has developed a revolutionary composite material that can completely contain EV battery fires and prevent them from spreading. In addition to enhancing fire safety, their material improves battery performance in cold temperatures and helps reduce noise inside electric vehicles.

In this interview with CEO Vamekh Kherkheulidze, we delve into how their innovation is transforming EV safety and expanding into industries such as aerospace and defense.

This interview is part of our exclusive Scouted By GreyB series. Here, we talk to the founder of innovative startups to understand how their solutions address critical industry challenges and help ensure compliance with industry and government regulations.

Thermal Runaway Suppression System that monitors battery temperature continuously and can prevent fire accidents

Huawei has developed a smart fire suppression system for EV battery modules in partnership with China’s University of Science and Technology.

The system is built into a specially designed battery box and includes a controller, temperature sensor, spray device, and extinguishing agent pipeline strategically placed above the battery cells.

How it addresses fire hazards:

- When the sensor detects that the battery temperature rises above a set threshold, it sends a signal to the controller. The controller then activates the spray device to release an extinguishing agent directly onto the overheating cells.

- The overhead placement of the spraying system ensures that the extinguishing agent is delivered quickly and directly to the source of heat, stopping thermal runaway from spreading to nearby cells.

- By reacting instantly and only when needed, the system helps prevent fires, protects the battery module, and lowers the risk of further damage.

This innovation adds an essential layer of safety to electric vehicles by responding to battery failures in real time, before they escalate into serious fire hazards.

Automatic Fire-Blocking Device to suppress EV Battery fire

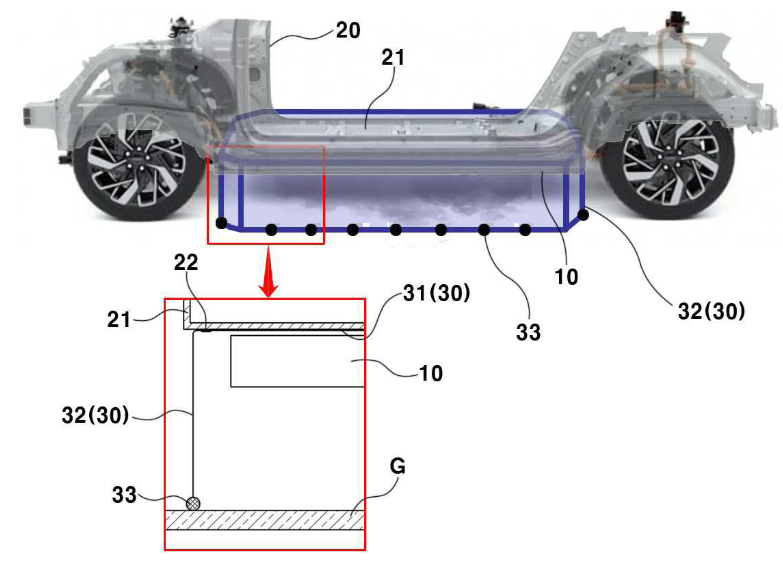

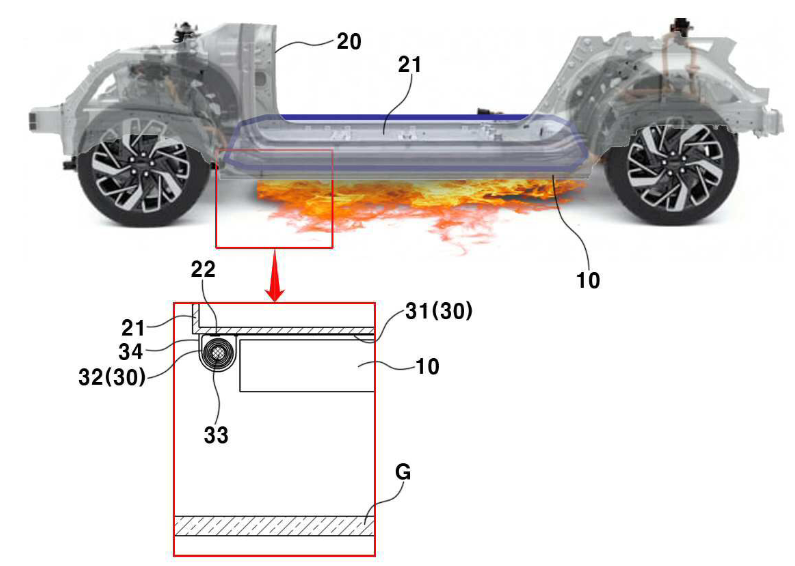

Traditional fire extinguishers often fail to control battery fires due to the complex design and materials used in EV battery packs. Hyundai has developed a fire suppression system for electric vehicles (EVs) that uses a self-deploying fireproof blanket to contain battery fires. This system has a safer, faster, and more targeted response.

How it addresses fire hazards:

- Fireproof Blanket with Built-In Deployment Mechanism: The blanket is installed above the battery pack. Its sides are rolled or folded and held in place using a heat-sensitive fixing system.

- Automatic Release and Oxygen Cutoff: When the system detects high heat or fire, the fixing mechanism melts, allowing weights attached to the blanket’s sides to pull it down over the battery. This action cuts off oxygen, helping to smother the fire.

- Full Coverage for Fire Containment: The blanket covers the top and sides of the battery, forming a closed shield that limits fire spread and reduces the risk of further damage.

Source: Patent

This solution offers a quick, passive fire-blocking method that operates without human intervention. This makes it especially useful for public transport vehicles, where protecting passengers and limiting damage is critical.

This fire-resistant composite material can save EV Batteries from Thermal Runaway

Henkel AG has developed a special fire-resistant material to enhance the safety of electric vehicle (EV) batteries in the event of overheating or fire.

Here’s how it works:

- Fire Barrier Layer: It combines a flame-proof coating with a tough fabric-like layer (made of glass fiber). This slows down the fire and protects the battery parts inside.

- Stays Strong Under Heat: The material doesn’t easily break or collapse when the battery heats up or faces pressure, helping prevent further damage.

- Light and Compact: Even though it offers strong protection, it’s very thin and lightweight—perfect for tight spaces inside EVs.

- Eco-Friendly Option: A water-based version is available that’s safer for the environment and doesn’t release harmful gases during a fire.

This solution makes EV batteries safer without adding much weight or size, while also offering a greener manufacturing choice.

Henkel’s innovation in the EV sector reflects an evolving interest from materials companies in solving EV-specific challenges, bringing new expertise into battery safety.

CBG Composites has developed a similar fire-resistant multi-layer composite laminate panel for EV battery housing.

Download the complete version of this report to learn what’s unique about the CBGs’ innovation.

You’ll also find information on more handpicked emerging innovations and trends (excluded from this article), determining the EV industry’s future. It will also answer questions like:

- Why do these emerging innovations matter for the EV industry?

- Who are the major players and collaborators in EV technologies?

- What challenges are slowing down EVs’ growth?

- How are companies tackling those challenges with these emerging technologies?

Get the Report in your Inbox

Fill the form to get access to the report