The stand-up pouches market is projected to expand at a notable CAGR of 7.41% from 2021-2028. By 2028, the market is poised to reach a valuation of USD 41.60 billion.

While the surge in demand for on-the-go snacks and single-serve meals, along with evolving consumer preferences, has driven this anticipated growth, there’s a critical aspect companies need to address. The unwavering commitment of governments and companies from 175 nations to curb plastic usage brings sustainability to the forefront of the packaging landscape.

In light of this global call for eco-conscious packaging solutions, innovation in sustainable stand-up pouches has accelerated. Companies recognize that adhering to sustainability guidelines is paramount despite remarkable projected growth. In this article, we highlight the top innovators and collaborations driving progress in this field and offer insights on how you can be the next one to ride the wave.

Companies researching sustainable stand-up pouches

1. VTT uses cellulose technology

VTT Technical Research Centre of Finland Ltd is a state-owned and controlled non-profit limited liability company. They have developed lightweight 100% biobased stand-up pouches using their patent-pending enzymatic fibrillation of cellulose (HefCel) technology.

Due to the different biobased coatings on a paper substrate, the pouches exhibit efficient barrier properties against oxygen, grease, and mineral oil. They are suitable for packaging fatty dry foods like crisps, potato chips, and muesli. The technology has been in the research phase since 2015 and produces high-consistency nanocellulose with low-energy industrial mixers. The resulting nanocellulose consistency is 15-25%, significantly higher than traditional methods at 1-3%. VTT plans to launch the pouches commercially in two to three years.

2. ProAmpac

ProAmpac is a leading global flexible packaging company that has developed a new, patent-pending recyclable retort pouch, ProActive Recycle Ready Retort RT-3000, suitable for pet and human food. The pouch is available in stand-up and three-side configurations and complies with EU and FDA food contact regulations for retort applications.

This mono-material pouch addresses the recycling challenges posed by difficult-to-recycle multi-material pouches used in retort applications. The RT-3000 offers filling and processing speeds similar to those of non-recyclable multi-material structures.

During the multi-year development, the pouch underwent successful validation on high-speed filling lines and qualification in commercial retort chambers. It provides exceptional thermal stability, grease resistance, easy-open tear performance, and superior oxygen- and moisture-barrier properties. The RT-3000 can withstand aggressive retort conditions without compromising its barrier properties.

Available in transparent and opaque versions, these sustainable stand-up pouches boast excellent stiffness, high puncture resistance, and flex-crack resistance, making it visually appealing on the shelf. Additionally, it has a high potential for recovery during advanced recycling, contributing to a circular economy approach.

Patent: US20210394496A1

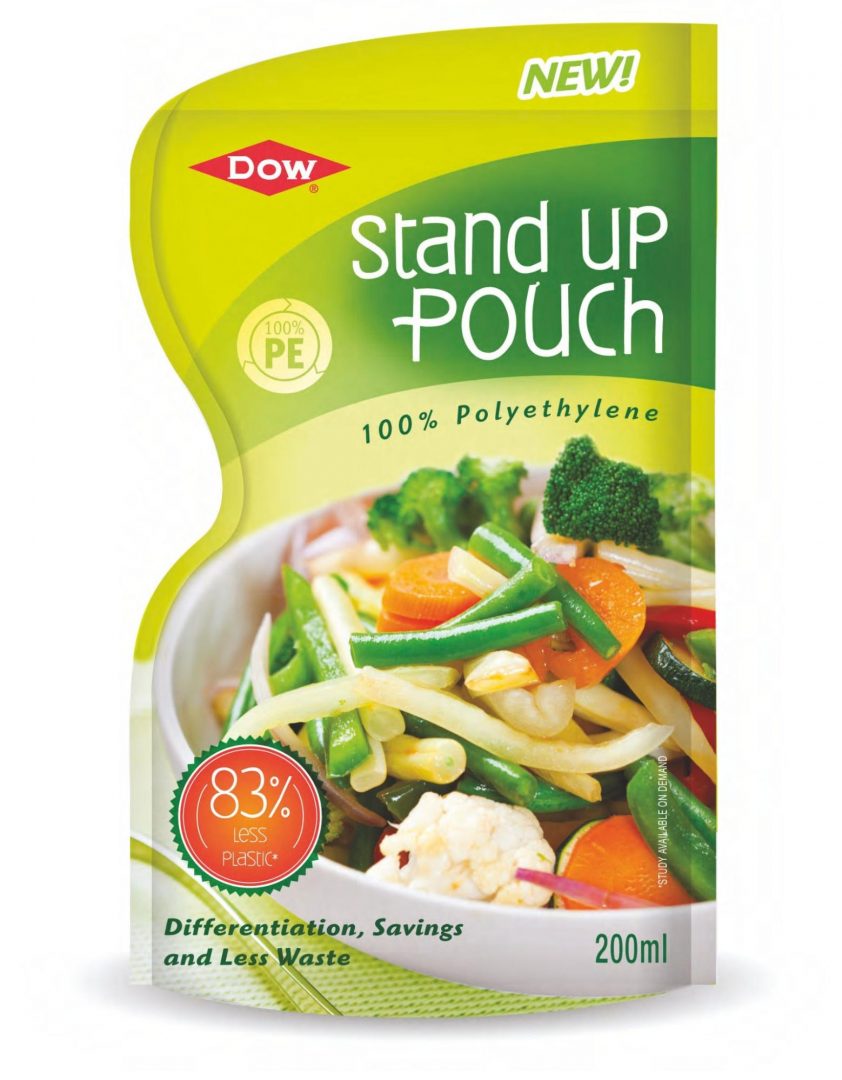

3. Dow

Dow Chemical Company, an American chemical and plastics manufacturer, is one of the world’s leading suppliers of chemicals, plastics, synthetic fibers, and agricultural products. Headquarters are in Midland, Michigan, and it was founded in 1897 by chemist Herbert H.

Dow has introduced an innovation in flexible packaging with its 100% Polyethylene (PE) Stand-Up Pouch (SUP). This new pouch is a sustainable, fully recyclable solution, marking a significant advancement in the packaging industry.

The Stand-Up Pouch has gained popularity due to its convenience and visibility on supermarket shelves. However, traditional SUPs often contain multiple materials, making them difficult to recycle. Dow’s new 100% PE SUP addresses this issue using only one raw material, polyethylene, simplifying the recycling process.

The 100% PE Sustainable Stand-Up Pouches (SUP) offer various benefits across multiple sectors, including cleaning products, beverages, cosmetics, dry and frozen foods, and construction materials. It provides full, durable sealing to prevent leaks, excellent puncture and tear strength, and a high level of recyclability thanks to its nanomaterial composition.

Dow’s resins and adhesives used in SUP production offer high strength and lower sealing temperatures, making the sealing process more efficient. The pouch also exhibits exceptional moisture and oxygen barrier properties, ensuring product freshness and quality.

This innovative packaging solution supports a circular economy, as it can be easily recycled in both pre and post-consumption stages. With its outstanding performance, convenience, and sustainability, Dow’s 100% PE Stand-Up Pouch is set to revolutionize how consumer goods are packaged and delivered worldwide.

Patent: US20220088886A1

Addressing Challenges In the Sustainability Of Stand-Up Pouches Through Collaborative Efforts

Collaboration between Mondi AG and Werner & Mertz GmbH

Pouch recycling poses challenges due to multiple polymer layers mixing during the process and ink from labels affecting the quality of recycled plastic.

The collaboration between these two companies aims to solve these problems, and in their pursuit of creating a fully recyclable stand-up pouch, they have employed a unique approach. They introduced a separate label film attached to the front of the pouch using a thermal seam weld. This innovative design allows for easy removal of the label film by tearing it apart from the pouch before recycling. As a result, both the pouch and the label can now be recycled efficiently.

The companies have patented this technology; more details are available here.

Collaboration between General Mills and Hershey’s

Stand-up pouches cannot be stacked on a shelf due to the low structural strength of the flexible films. Stores and other places that use them do not do well with this limitation. Therefore, General Mills and Hershey’s have aimed to solve this problem by making a self-supporting flexible film container.

General Mills and Hershey’s have patented a container and a method for manufacturing it. The new packaging incorporates tubular support columns into the container’s walls, increasing strength and rigidity. These columns are made up of the same material as the walls. This makes the containers easier to stack, display better, and easier to open.

Collaboration between Frito-Lay and Douglas Machine

Machinery for pillow packages has been available for a long time, but stand-up pouches offer several advantages over pillow packages. They can stand upright, making product visibility and branding easier. Therefore, using pillow package machinery to make stand-up pouches will reduce upfront costs and facilitate the transition.

Frito-Lay and Douglas Machine have collaborated to solve this problem. Their patent describes a method to manufacture structurally resilient packages using pillow packages as input. The basic setup is to receive a pillow package, condition it by rocking and jolting, then heat it to deform it, shape its base and top in square ends, and finally cool it to fix the shape. Optionally, hem seals can be provided at the edges to improve structural resilience.

Conclusion

Global efforts to reduce plastic use and promote sustainable alternatives have prompted companies to innovate and collaborate to address the challenges of stand-up pouch recycling and structural limitations.

They pave the way for the sustainable stand-up pouch market and highlight the importance of industry-wide efforts to promote environmentally friendly packaging solutions. More innovative approaches and partnerships will follow, as the industry heads in a sustainable direction.

Stand-up pouches have been trending amongst consumers, and if they are sustainable, that’s just icing on the cake.

Since the industry has plenty of white space, you can carve a niche for yourself by conducting a thorough landscape analysis. You can seek potential collaborators who align with your business objectives from there.

And, with GreyB’s expert guidance, the process becomes relatively easy. All you need to do is

How Can We Help You?

We support industry-leading R&D and Innovation professionals through complex problems. Describe your challenge, and let us bring clarity and expertise.

Authored by: Aman Maurya, Patent Analytics