Coffee production is a water-intensive process that requires large amounts of land, contributing to deforestation and a significant carbon footprint. As global demand continues to grow, the environmental impact intensifies, posing a threat to the industry’s long-term sustainability. With the looming concerns of climate change and resource scarcity, the search for sustainable alternatives is on.

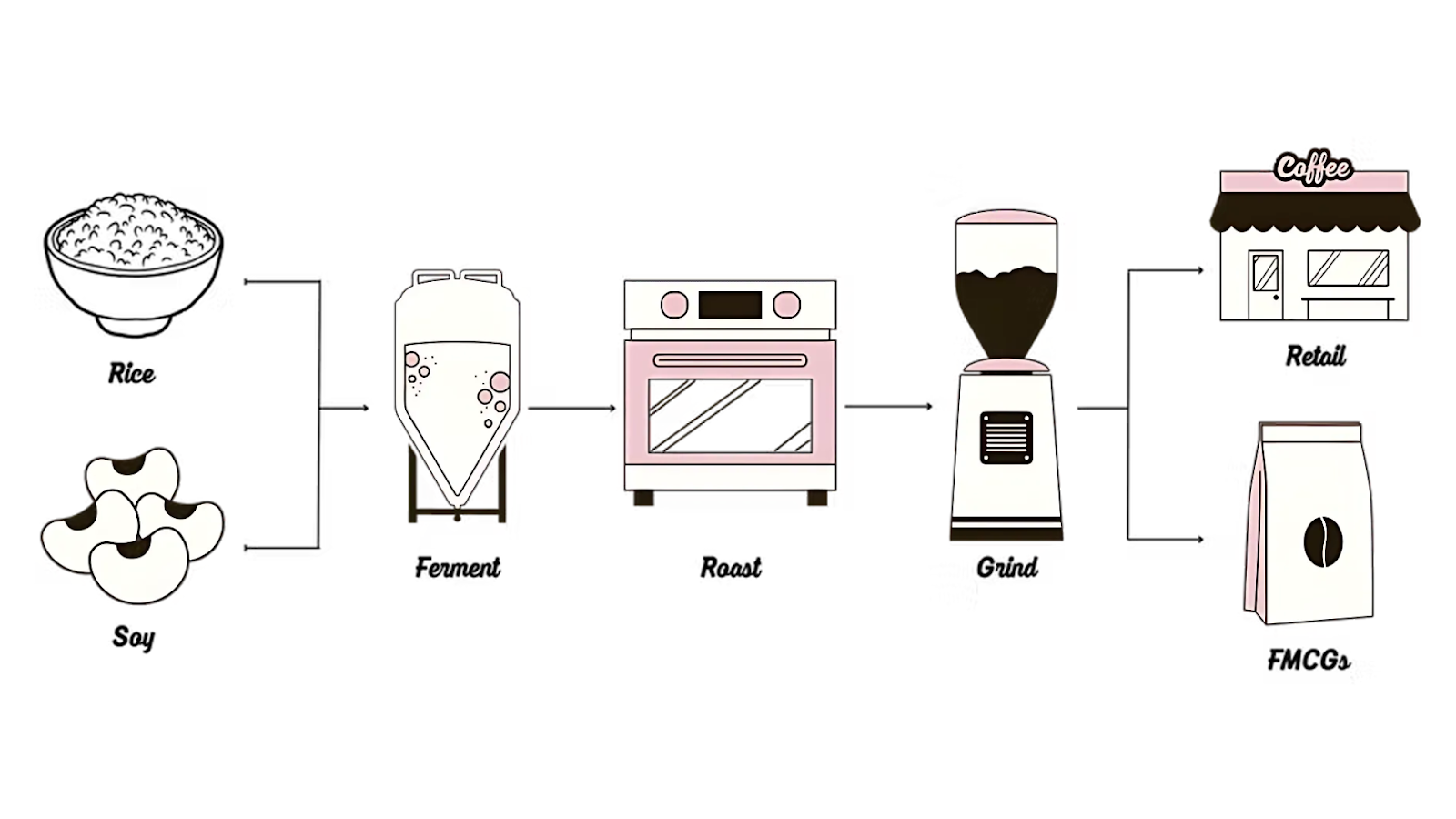

A startup called Prefer Coffee has a solution that replicates coffee’s sophisticated flavors without using actual coffee beans. Instead, they use fermented agricultural byproducts, such as soy pulp, which are typically discarded, to create coffee-like aromas.

To better understand how their process works, we spoke to Jake Berber, CEO of Prefer Coffee. This article contains notable highlights from our entire conversation.

This interview is part of our exclusive Scouted By GreyB series. Here, we speak with the founders of innovative startups to understand how their solutions address critical industry challenges and help ensure compliance with industry and government regulations. (Know more about startups scouted by GreyB!)

“We’ve identified the exact microbes that can replicate the aroma volatiles found in coffee!”

– Jake Berber

Jake Berber is the CEO of Prefer Coffee. Jake studied Neuroscience at Claremont McKenna College and later earned an MBA in Entrepreneurship from Tel Aviv University and the National University of Singapore (NUS). He co-founded Prefer Coffee to create bean-free coffee using fermented surplus food, addressing climate change and supply chain issues.

How ‘Prefer Coffee’ Brews Bean-Free Coffee using Fermentation

By utilizing agricultural byproducts such as broken rice and soy pulp, Perfer uses a fermentation platform to replicate the complex aromas and flavors found in coffee. This approach significantly reduces the carbon footprint compared to conventional coffee farming, making it a more environmentally friendly option in an increasingly eco-conscious market.

How do you replicate the same coffee flavors without using coffee beans?

Jake: We’ve developed a fermentation technology that creates the same aroma and flavors found in coffee, but using raw inputs such as food industry byproducts, including broken rice and soy pulp. Our fermentation method uses microbes, enzymes, and yeast to break down the amino acids and starches in these byproducts, essentially reverse-engineering the signature flavors of coffee.

Could you elaborate on the scientific principles underlying your fermentation process? What distinguishes it from traditional methods?

Jake: Traditional fermentation is indeed an old process, but we’ve innovated by discovering specific microbes, yeast, and enzymes that can break down these agricultural byproducts to release the exact aroma and flavors found in coffee. We’ve essentially modernized this process by targeting specific compounds that mimic the flavors and aromas that coffee lovers know and love. This approach can also be applied to other flavors, such as chocolate, which we plan to launch later this year.

Is maintaining flavor consistency a challenge given the variability of fermentation?

Jake: Yes, fermentation is an art as much as a science. We ensure consistency by having strict standard operating procedures in place and sourcing our feedstock from trusted partners. From there, we enforce rigorous internal procedures to consistently treat these ingredients, ensuring that the end product is uniform in both flavor and aroma. By receiving consistent ingredients, we can maintain the same consistent flavor profiles from batch to batch, which is key to delivering a high-quality product.

What makes Prefer’s solution more sustainable compared to traditional coffee production?

Jake: Our coffee production uses significantly less CO2 than traditional coffee farming, approximately five times less. Additionally, 100% of our ingredients are upcycled, and we use approximately 95% less water and land. Third-party LCA verifiers are still validating these numbers, but we’re confident in the sustainability of our approach.

How scalable is Perfer Coffee’s production process?

Jake: The beauty of our solution is that the raw materials we use, like broken rice and soy pulp, are available globally and can be sourced locally. This means that we can scale production without worrying about sourcing limitations. Unlike other startups that face challenges with sourcing their materials, we can access these byproducts from numerous locations worldwide.

Do you foresee any scalability challenges as you expand?

Jake: As long as we can maintain partnerships for a steady supply of raw materials, scalability shouldn’t be a problem. Since we use widely available byproducts, we can expand our production without worrying about supply chain disruptions. Our process is also highly flexible, enabling us to adapt to various regions and markets as we grow.

Meet our Interviewer – Shabaz Khan, Marketing Manager at GreyB

Shabaz Khan, Marketing Manager

Want to find other scalable startups innovating in Sustainable Foods and Beverages? Please fill out the form below to contact our experts.

Get in touch

Please share your query below