Millions of Wireless IoT sensors deployed in factories, shipping yards, railways, and other locations run on disposable batteries. Sometimes, these industrial sensors are so compact and epoxy-sealed that the entire sensor is trashed when the battery runs out. Globally, we discard around 80 million batteries daily. This not only creates massive environmental waste but also introduces high maintenance costs and downtime in critical operations.

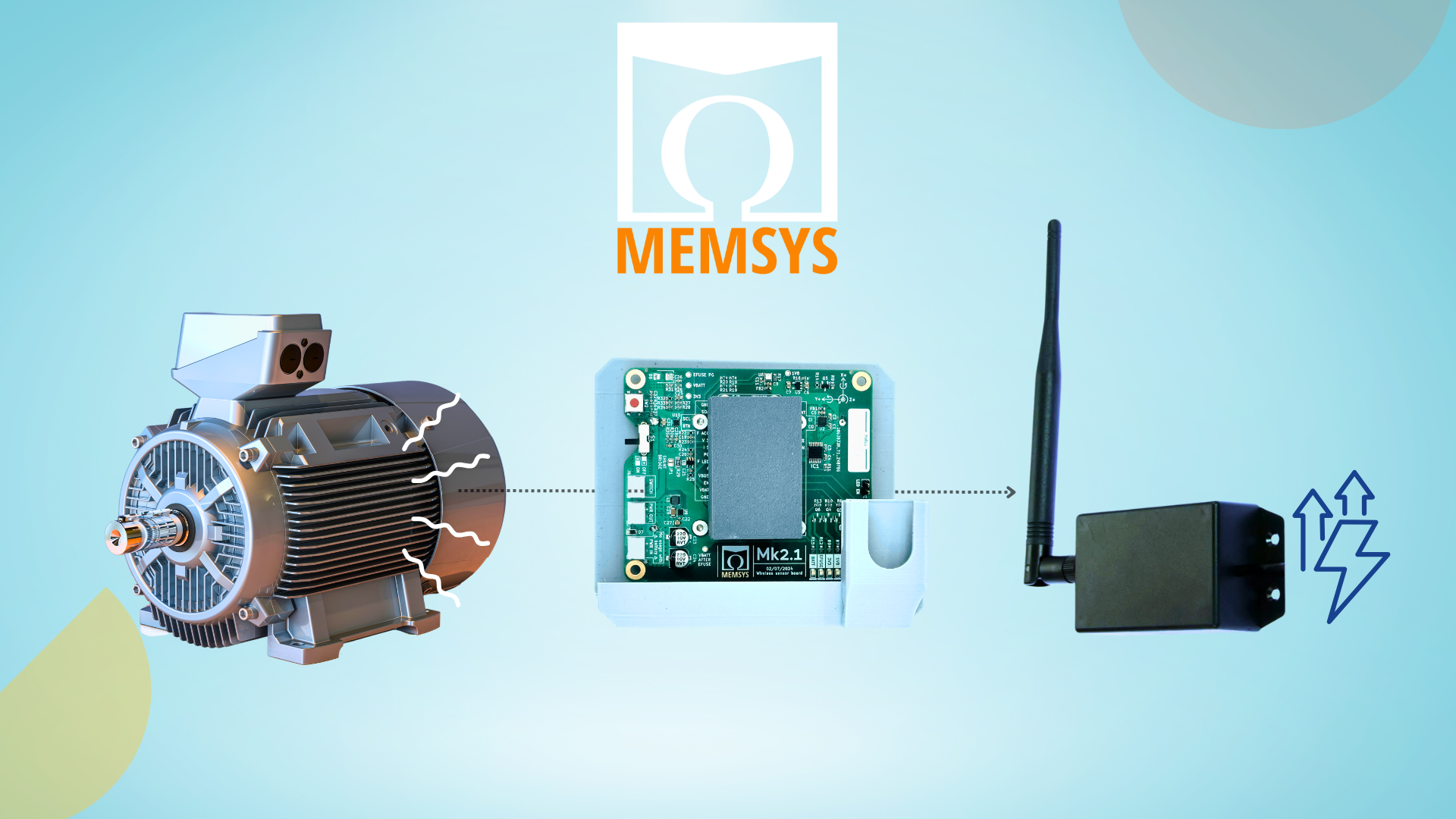

A startup named MEMSYS is developing a new type of power harvester that harnesses ambient vibrations to generate a consistent energy source. MEMSYS has already demonstrated prototypes that generate over one milliwatt of power using this system. This performance could allow industrial sensors to operate up to six times more frequently than if powered by batteries.

To better understand how their process works, we spoke to Thijs Blad, CEO of Memsys. This article contains notable highlights from our entire conversation.

This interview is part of our exclusive Scouted By GreyB series. Here, we speak with the founders of innovative startups to understand how their solutions address critical industry challenges and help ensure compliance with industry and government regulations. (Know more about startups scouted by GreyB!)

“We’re throwing away 80 million batteries a day, plus 40 million sensors. MEMSYS is here to fix that.”

– Thijs Blad

Thijs Blad is the Founder & CEO of MEMSYS, a company specializing in kinetic energy harvesting for self-powered industrial devices. He holds a PhD in Mechanical Engineering from TU Delft, focusing on energy harvesting from mechanical vibrations. Thijs founded MEMSYS in 2022 to bridge the gap between academic research and commercial applications, particularly in Industrial IoT (IIoT) solutions.

Overview: MEMSYS Wants to Power the IoT – No Wires, No Batteries!

Rather than relying on solar or heat-based solutions, MEMSYS harvests power from the one thing every machine creates: vibration. Their compliant mechanism, coupled with piezoelectric materials, allows the device to function even when vibration patterns shift. This overcomes a significant limitation of existing energy harvesters that only work in narrow frequency ranges. MEMSYS is currently collaborating with sensor manufacturers and predictive maintenance providers to integrate their energy harvesters into real-world applications, ultimately miniaturizing them into MEMS devices for full PCB integration.

How does MEMSYS technology work?

Thijs: We use compliant mechanisms, flexible structures that bend instead of rotate, to stay in tune with constantly changing vibrations. These mechanisms deform and transfer motion into piezoelectric elements that produce electricity. Unlike traditional resonators, which sharply lose efficiency if the vibration frequency changes by just a few hertz, our structure performs across a much wider band.

This means we can continue harvesting energy even when the vibration source, such as a motor, changes speed. In one prototype, we generated over one milliwatt of power across a 40 Hz bandwidth, centered around a 50 Hz vibration source. It’s a small amount of power, but enough to run many types of industrial IoT sensors much more frequently than battery-powered alternatives.

How does your power output compare to other harvesters on the market?

Thijs: Other harvesters may look great on paper, but they only perform well in tightly controlled lab conditions. If the vibration shifts by a few hertz, their power output can drop by 90%. We chose a different trade-off—we generate slightly less peak power, but we sustain that power over a broad frequency range. That means our system is far more reliable in real-world environments.

With our recent prototype, we could guarantee one milliwatt of power across a real industrial setting, enough to measure and transmit six times more frequently than battery-based systems. So instead of checking your vibration sensor once per hour, you could check it six times. That’s game-changing for predictive maintenance.

What industries or applications are you targeting?

Thijs: We’re focusing on predictive maintenance—industries like railways, steel manufacturing, pumps, or any system that runs 24/7 and generates vibrations. These systems often use sensors to monitor performance and schedule maintenance. But the challenge is that these sensors either need wiring or batteries, which don’t scale well. Our energy harvester can be plugged into existing sensors and provide a consistent power source, even in hard-to-reach places.

We’re also exploring applications such as asset tracking, Bluetooth beacons, and eventually, MEMS-scale sensors that can be directly integrated onto circuit boards. However, our first step is to install external power boxes for predictive maintenance sensors, followed by internal modules that replace existing batteries.

How easy is it to integrate your system into existing sensor networks?

Thijs: Pretty straightforward. Our first product is a kind of plug-and-play power box. It connects to your existing sensor and extends its lifetime while boosting performance. We’re also developing smaller modules that can replace internal batteries, and eventually, we’ll scale down to full MEMS devices.

We’re working closely with both sensor manufacturers and end users. The goal is to provide a power solution that doesn’t require companies to redesign their sensors—just upgrade how they’re powered.

Are you facing any manufacturing challenges?

Thijs: Yes, especially as we move toward MEMS-scale production. Our compliant mechanisms rely on controlled buckling—intentionally pushing a material to its limit to create a helpful response. At the macro scale, it’s manageable. But at the MEMS scale, where we’ll use materials like silicon instead of spring steel, it’s much harder.

We’re actively developing models and manufacturing strategies to handle this. One idea is to embed the preload stress during fabrication, rather than applying it through manual compression. It’s a deep engineering challenge, but it’s what we’re focused on now.

Could this tech one day power wearables or automotive systems?

Thijs: Absolutely. Smart shoes already use similar energy harvesting methods. In clothes, it might be more force-based than vibration-based, but it’s doable. For electric cars, powering the entire battery is unrealistic. But powering individual tire pressure monitoring sensors? Totally feasible. We can place a local harvester right in the wheel that powers the sensor from its motion—no wires, no battery swaps.

Who’s your ideal customer?

Thijs: We’re looking to partner with both sensor users and manufacturers. Users benefit from longer sensor life and improved data quality. The manufacturers help us integrate our harvester into their devices. It’s a two-sided equation.

Ultimately, the end-user doesn’t care how the sensor is powered. But they do care about performance and maintenance. If we can offer longer life and more frequent readings without extra cost or hassle, then that’s a win for everyone.

Meet our Interviewer – Shabaz Khan, Marketing Manager at GreyB

Shabaz Khan, Marketing Manager

Want to find other scalable startups innovating in IoT and Battery Tech? Please fill out the form below to contact our experts.

Get in touch

Please share your query below