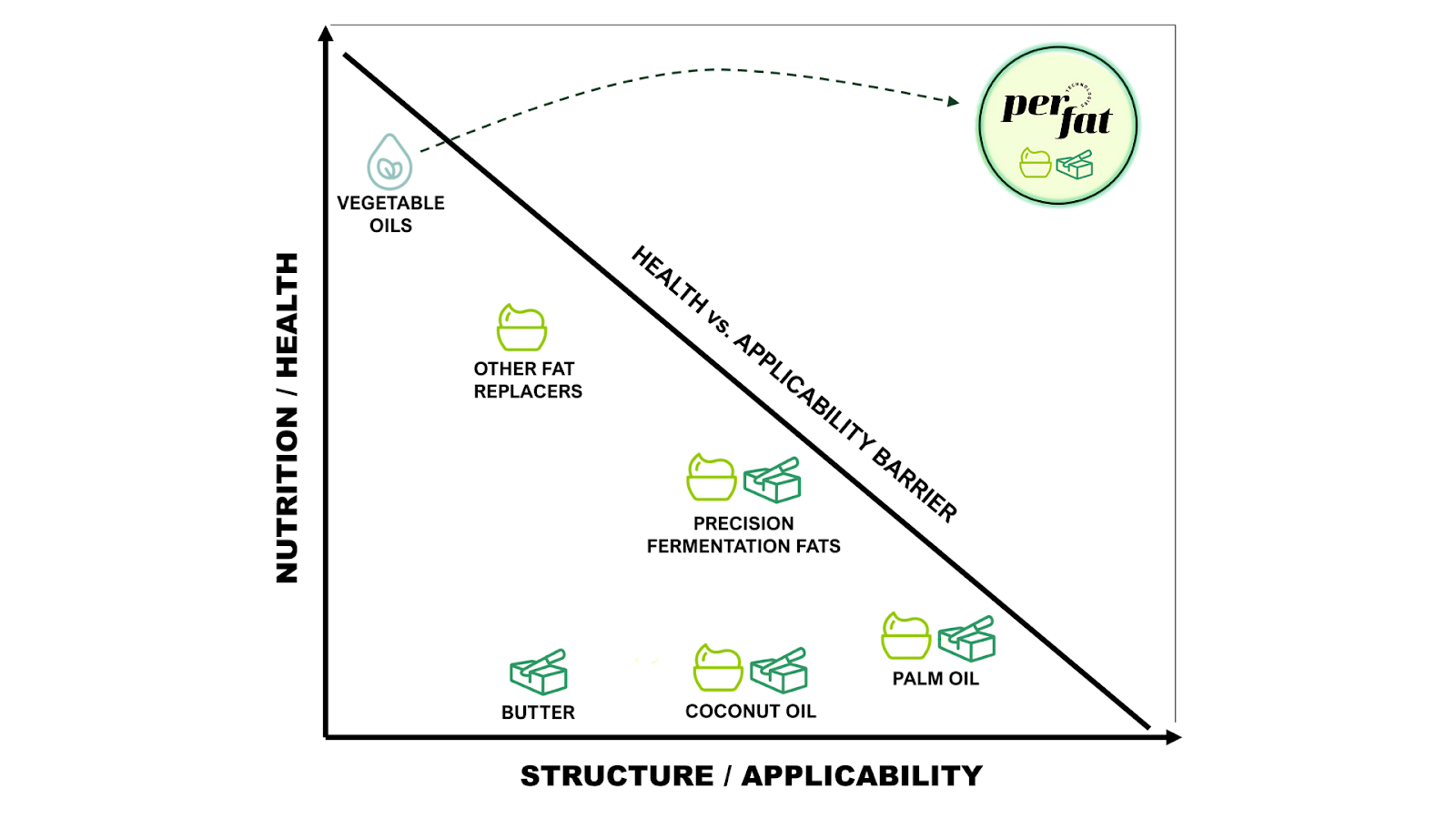

About 70-75% of adult diets exceed the 10% saturated fat limit recommended by the WHO. This contributes to obesity and metabolic syndrome. In some European countries, it exceeds 27.5% of total energy intake! Replacing these fat compounds with healthier replacers, without compromising taste or mouthfeel, has become a significant challenge for food manufacturers.

This article details how some startups are creating fat replacers for foods, addressing these issues by offering healthier and more sustainable alternatives to traditional fats. These innovations avoid the bitter aftertastes commonly associated with typical fat replacers, such as Caprenin and Benefat. They can be used in a variety of products, including chocolates, spreads, and meat substitutes.

These technologies focus on reducing calories, saturated fats, and environmental impact while maintaining the desired textures and functional properties of fats.

More trends are emerging in the food-tech space that R&D leaders must keep up with. Here’s a comprehensive report discussing the Food technology trends that will influence the market in the coming months.

Perfat turns oil into solid fats with 80% fewer calories!

A Finland-based startup named Perfat has developed proprietary fat replacers. It’s an oleogel technology that converts healthy oils into semi-solid or solid fats. These solids have 30% fewer calories than coconut oil, 80% less saturated fat, and 30% more dietary fibre than traditional fats.

The emulsion is a mix of sunflower or candelilla wax with grapeseed oil and cellulose nanocrystals, followed by encapsulation with corn fiber and spray-drying at 170 °C. They then combine the powder with a melted gel of natural fat monoglycerides. Finally, the oleogel is coated with corn-based fiber for protection and controlled release.

The converted fats can be used in chocolates, spreads, ice creams, baked products, meat alternatives, and dairy alternatives.

Early trials indicate positive feedback, particularly regarding the enhanced taste and juiciness of these reinforced oleogel products. However, broader consumer acceptance is still being gauged as the products move toward market introduction.

Perfat’s oleogel technology is designed for large-scale food production and tested with off-the-shelf equipment. Their products are designed to prevent oxidation, extending product lifespan. Their controlled fat release also helps improve product stability over time. The company has raised €1 million in seed funding and is generating €300,000 in annual revenue, indicating early commercial traction.

Microlub’s Protein Microgels Reduce Fat by 75% with No Compromise on Taste.

Microlub, a UK-based startup founded in 2023, has developed protein-based technologies for fat replacement that reduce the fat content and calorie count of food products by up to 75% without affecting their taste or texture. It also helps overcome the challenge of occasional unpleasant aftertastes associated with traditional fats.

The company has developed an oil-free additive formulation consisting of two key components:

First, a Proteinaceous microgel comprises proteinaceous material, such as potato protein, lactoferrin, or other types of proteins (e.g., whey protein, casein, etc.).

The solution is prepared by first dissolving the protein material in a food-grade buffer solution with a pH range of 3 to 7. Next, heat the solution at a specific temperature for a specified time to denature the protein and create a gel. Finally, break down larger gels into smaller microgels with specific charges through homogenization.

Second, a Biopolymeric hydrogel comprises xanthan gum, alginate, carrageenan, pectin, or other polysaccharides.

A similar method is used to make biopolymeric hydrogels. First, the protein microgel is mixed into the biopolymeric hydrogel solution. Due to their opposite charges, microgels and hydrogels attract each other. This attraction creates a coating of biopolymeric hydrogel around the protein microgel, resulting in a composite structure that mimics the fatty feel in food products.

Unlike previous protein microgel alternatives, Microlub’s microgels reduce friction by two orders of magnitude, mimicking the full-fat sensory experience of a smooth, creamy texture without adding fat.

Securing consistency across large batches and scaling production to meet industrial demands remains a challenge for the startup.

The oil-free additive can be used in various products, including dairy-based, plant-based, baked goods, confectionery, and spreads, without leaving any aftertaste. Blind taste tests have demonstrated that consumers cannot distinguish between full-fat and reduced-fat products using Microlub’s technology, suggesting strong potential for market acceptance.

Comparison of Gel vs. Traditional Emulsion Fat Replacers:

| Aspect | Traditional Fat Emulsions | Gel-based Fat Replacements (e.g., Oleogels, Microgels) |

| Texture | Rich, smooth, creamy mouthfeel | Mimics fat texture but may require fine-tuning to match mouthfeel |

| Stability | Can break down over time (phase separation) | More stable, with less separation and improved shelf life |

| Fat Reduction | No fat reduction, mainly used to emulsify fat in products | Can reduce fat content by 75% or more, with lower calories and saturated fat |

| Consumer Acceptance | High (familiar product) | Positive, but requires consumer education to accept new textures and ingredients. |

Finding promising fat replacers that meet your taste, texture, and scalability needs will take digging through hundreds of search results. This is where an AI-based research tool like Slate comes in handy.

You merely need to write a short sentence describing what you’re looking for. Within minutes, Slate scours through the latest research papers and patents to give you highly relevant information in an easy-to-read manner. Here’s a screenshot of what showed up when Slate was given a query: “What are the recent innovations overcoming the texture challenge in fat replacement technologies/alternatives?”

Slate also lets you “chat” with the research papers to find out more information within a few short questions! Try it out yourself using this simple form below:

Hoxton Farms Made Alt-Fat Production Scalable with Animal Cells

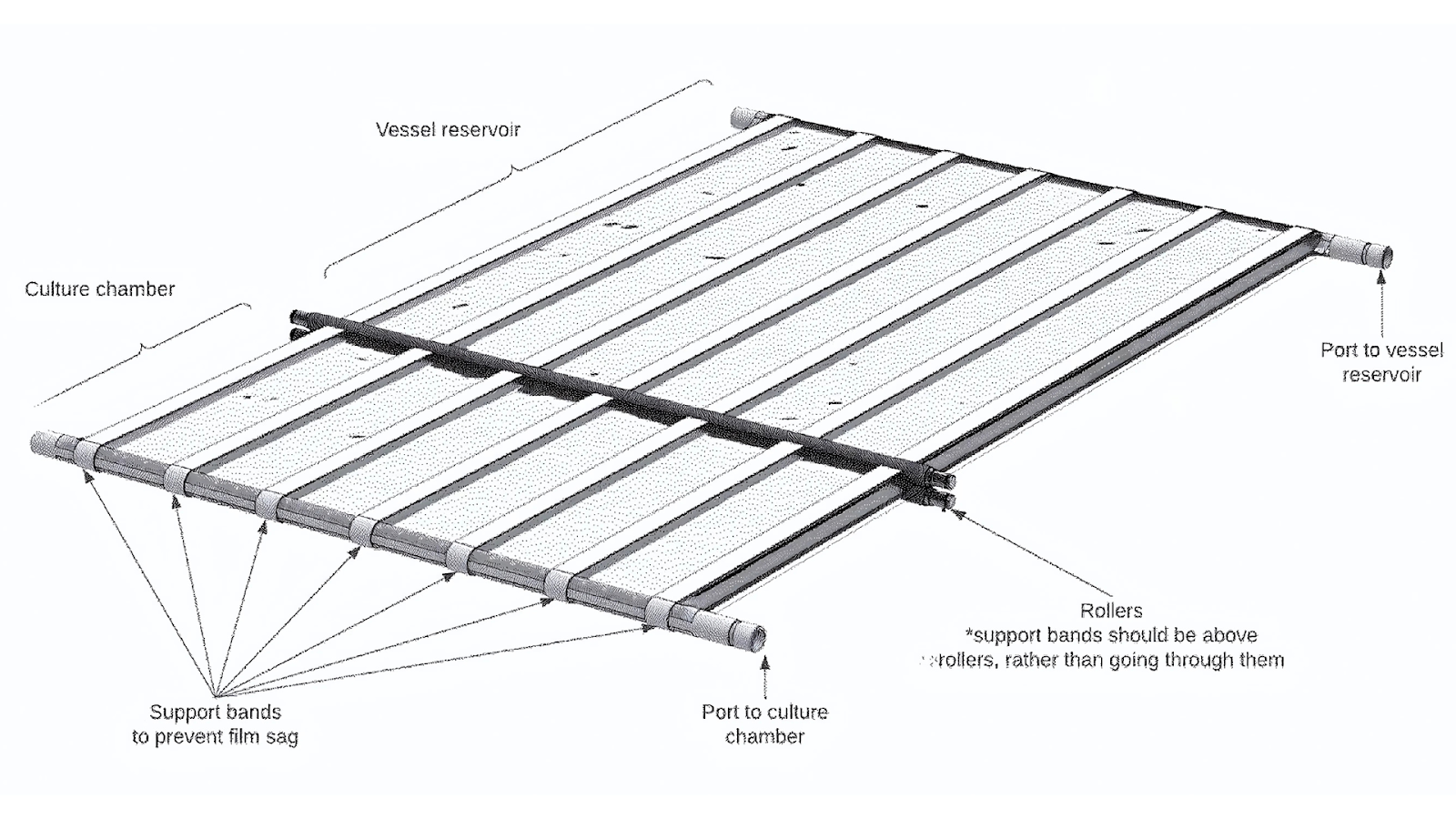

Hoxton Farms, a UK-based startup founded in 2020, grows fat replacers from animal cells in bespoke bioreactors. Instead of relying on massive and expensive single-unit bioreactors, their approach utilizes multiple smaller bioreactors connected through software and automation, thereby improving efficiency and achieving cost-effective scalability.

The startup has designed a system that produces adipocytes (fat storage cells) from multipotent or pluripotent cells, such as mesenchymal stem cells, which could be used in food products.

They start with a small sample of animal stem cells, which are then grown in bioreactor modules using a plant-based nutrient blend. Once the modules are ready, they move them to environmental chambers for cell growth and expansion.

This growth happens in stages, with adjustments made to the reservoir using rollers. Finally, they harvest, concentrate, and purify the cells, ensuring that the reactor modules are thoroughly flushed and cleaned.

The bioreactor developed by Hoxton Farms allows for the cost-effective cultivation of fat cells at high densities and yields, even on a large scale. Their modular system with incremental scaling reduces upfront investments, making this technology more accessible.

This cultured fat can be utilised in food products such as meat analogues, baked goods, dairy alternatives, and confectionery. This method is designed to be compatible with existing cell culture systems, enabling scalable production without the need for entirely new infrastructure. Additionally, their tech platform allows precise control over fat cell growth, making it compatible with existing industry bioprocesses.

ÄIO Upcycles Waste into Sustainable, Healthy Fats

An Estonian-based start-up named ÄIO is utilising precision fermentation with a proprietary, non-GMO yeast strain to produce microbial oils and fats from upcycled feedstocks such as sawdust and agricultural waste.

The microbially fermented fats they make are rich in healthy fatty acids and antioxidants. The products offer ethical, clean-label options that minimize waste and reduce environmental impact, promoting healthier consumer choices.

Based on this technology, the company has developed three product variants:

RedOil is a visually appealing alternative to vegetable, fish, and seed oils. It’s a mixture of beneficial compounds to serve as active ingredients in cosmetics and household chemical formulas. It contains natural antioxidants and carotenoids, enhancing flavor depth compared to conventional vegetable oils.

Encapsulated oil is designed for uses where texture is key. The formula substitutes palm oil, soybean oil, and nutritional yeast, especially in bakery products. It prevents oil leakage, ensuring a consistent texture in sauces and confectionery goods.

Buttery fat is the company’s substitute for butter-like products. Its texture mimics animal fat and coconut oil, providing a smooth, creamy texture ideal for spreads and baked goods.

Scaling the fermentation process and ensuring the consistency of oil quality are key challenges, mainly due to variability in raw materials, processing methods, and environmental factors. Additionally, educating consumers about the benefits and safety of microbial oils is essential for market adoption.

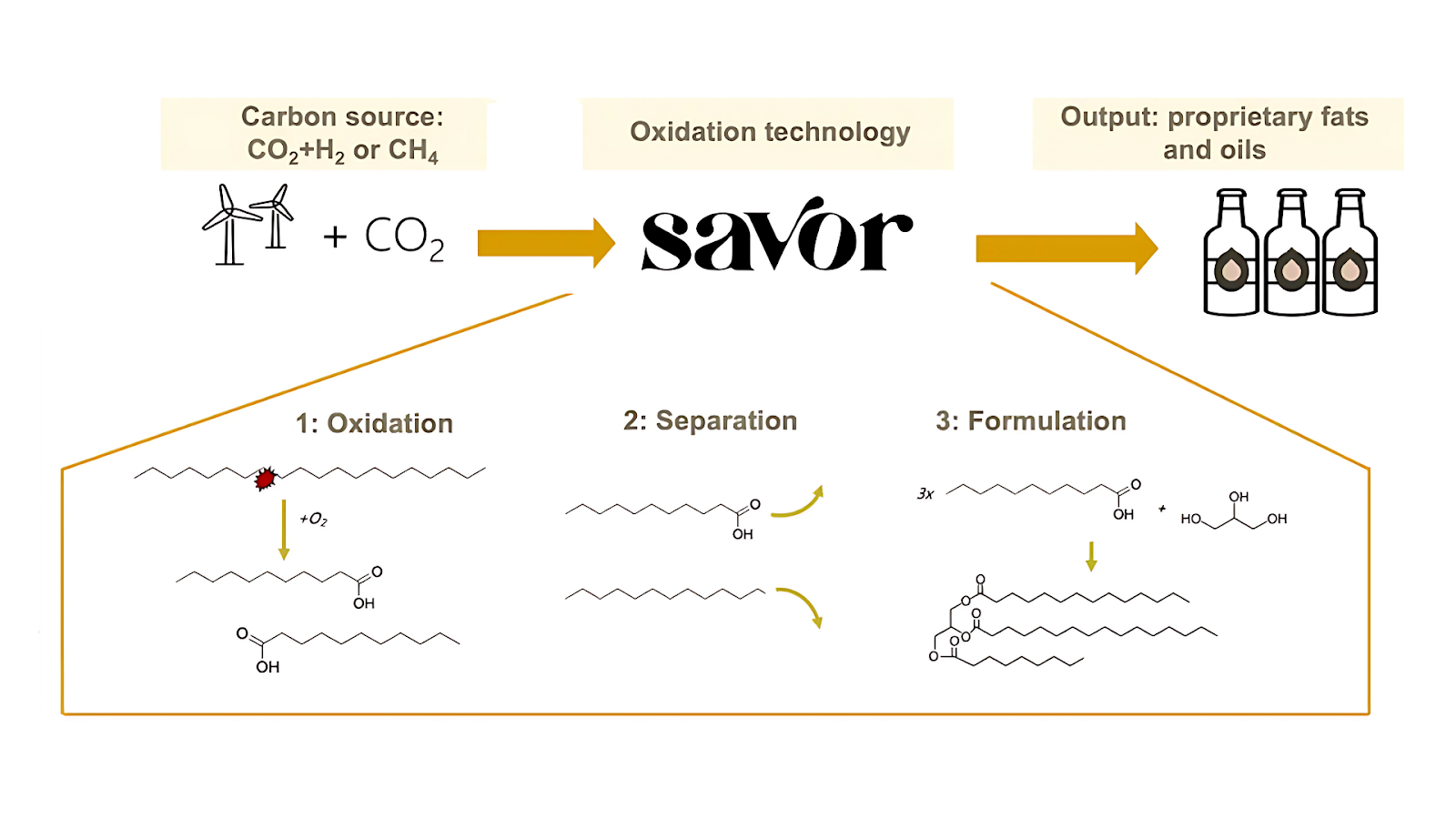

Savor Turns Carbon Emissions into Sustainable Lipids

Savor, a USA-based startup founded in 2022, has designed a chemically processed lipid formulation to replace traditional animal and hydrogenated fats in food.

Their patented method captures carbon from atmospheric emissions and combines it with hydrogen under high heat and pressure. These hydrocarbons undergo the oxidation process to yield hydroxyl compounds. Separating these hydroxyl compounds yields the desired fatty acids.

These fatty acids then undergo both interesterification and intraesterification processes. The interesterification process creates fatty acid esters from different fatty acids, while the intraesterification process uses the same fatty acids to form esters. This multi-step esterification process enables the customization of lipid properties by modifying the structure and composition of triglycerides. It also allows for precise control over fat structure, ensuring a smooth, buttery texture similar to dairy fats. Its high melting point makes Savor’s butter stable under heat, improving baking performance compared to hydrogenated fats.

Every year, the world emits 51 billion tons of greenhouse gases, and the production of fats and oils from animals and plants makes up seven percent. Savor’s technology has developed fats that help in reducing these emissions.

Traditional butter production emits 16.9 kg of CO₂ per kg of butter, mainly due to methane from dairy cows and energy-intensive processing. Savor’s butter emits less than 0.8 g of CO₂ per kg, representing a 99.95% reduction in emissions.

Savor has earned GRAS status for its first launched product, a butter made using this technology, which can be utilized in baking, confectionery, and dairy applications. The company has partnered with establishments like SingleThread and ONE65 in California to introduce menu items featuring this animal-free butter. Savor also plans to launch cocoa butter alternatives soon, expanding its portfolio.

Future Outlook

As consumer demand continues to shift toward healthier and more sustainable food options, there will be a significant increase in the commercialization and adoption of fat substitutes, also known as fat replacers. These include oleogels, protein microgels, cultured fats, precision-fermented oils, and carbon-captured lipids. These changes will be especially noticeable in high-fat categories, such as bakery, confectionery, dairy, and meat alternatives.

Early adoption and partnerships in reformulation projects will ensure a competitive edge in the industry. However, finding the right startup with scalable, regulation-friendly technology is no easy task.

GreyB’s startup scouting acts like a filtration system. Instead of chasing every other innovation out there, you get curated, technical insights that align with your formulation goals, production lines, and consumer needs.

Our experts benchmark these startups against performance, patents, production readiness, and potential regulatory hurdles.

Unsure whether a startup’s fat replacement tech can integrate into your production line or need a few options handpicked for your use case? Send us your query using the form below, and our experts will get back to you.

Get in touch

Please share your query below