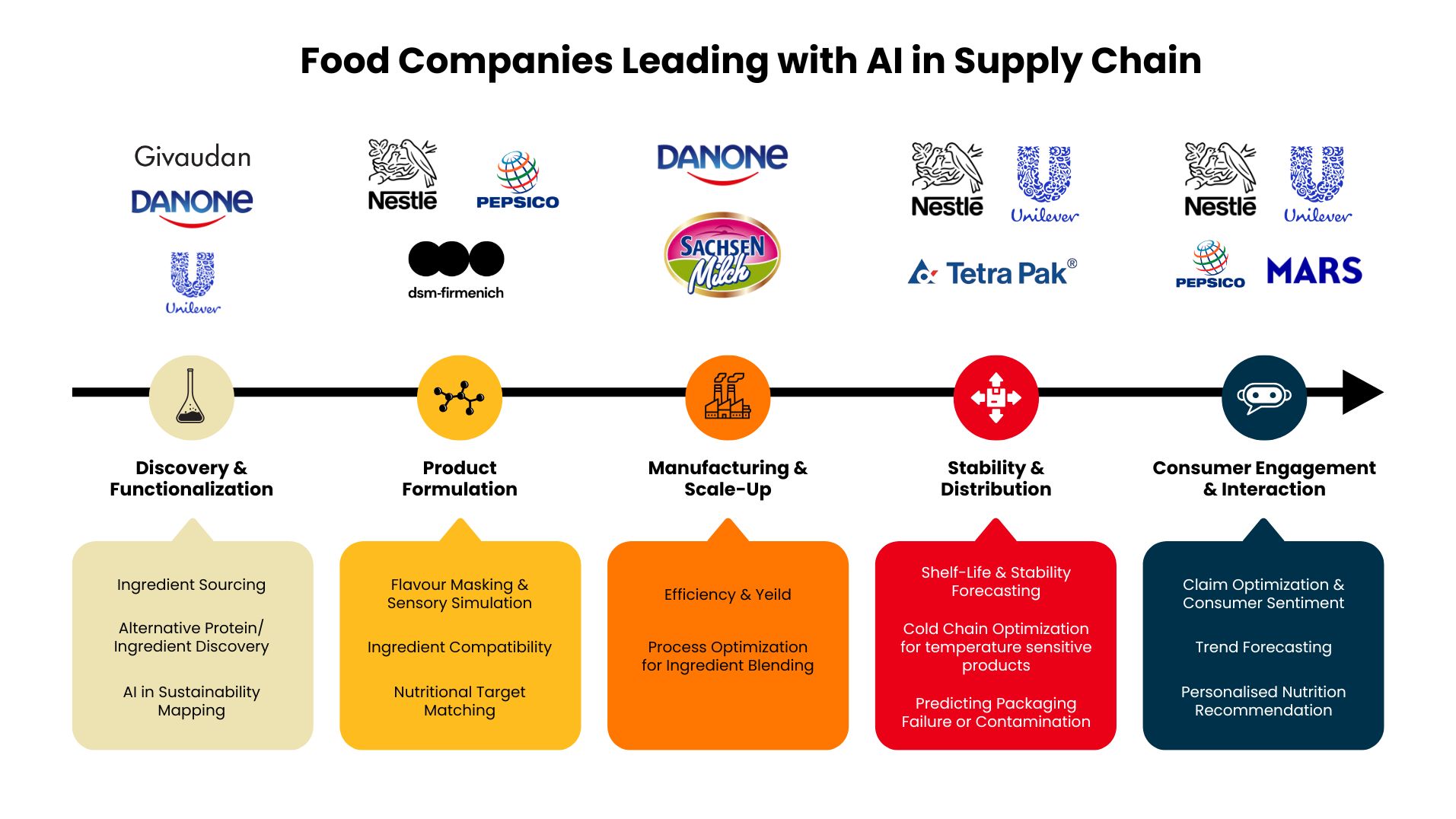

Food manufacturers today face increasingly complex supply chains, rising costs, fluctuating demand, and growing pressure for sustainability and safety. From ingredient sourcing to production, inventory management, and distribution, inefficiencies can lead to waste, delays, and lost revenue, leaders like Nestlé, PepsiCo, Unilever, and Danone use AI to cut R&D costs, speed up product development, boost manufacturing efficiency, reduce waste, and deliver personalized nutrition. The result: faster innovation, leaner operations, and stronger consumer loyalty.

Food giants like Unilever are leading the way by integrating AI across every stage of the food supply chain. From AI-driven ingredient discovery and product formulation to smart manufacturing, cold chain optimization, and personalized consumer engagement, Unilever demonstrates how AI can boost efficiency, reduce waste, improve product quality, and enhance sustainability – delivering measurable business results at scale.

Key Questions Answered in the report:

This exclusive report provides actionable insights into how leading companies are leveraging AI to transform their food supply chains. Key highlights include:

Unilever’s AI Strategy: AI across the supply chain—from ingredient discovery to consumer engagement—with 500+ projects and $8M+ in strategic investments.

Product Innovation: In-silico testing, flavor masking, and plant-based ingredient development for products like Knorr and Hellmann’s.

Smart Operations: AI-enabled freezers, digital twins, and demand forecasting boost on-shelf availability, reduce waste, and increase sales.

Collaborative Supply Chain: CPFR with Walmart Mexico delivers 98% on-shelf availability and 12% sales growth.

Future Outlook: Quantum computing and foundation models for advanced product optimization and consumer insights.

Don’t miss the opportunity to understand how AI is reshaping the food supply chain. Fill out the form below to access your copy of Innovations in AI in the Food Supply Chain and gain a competitive edge.