According to the International Energy Agency (IEA), to meet the increasing global energy demand, storage capacity must expand to 1,500 gigawatts (GW) by 2030. It also projects that 90% of this should come from batteries alone. However, current trends in the energy storage industry are creating a different picture.

While battery storage remains at the forefront, the landscape is becoming more diverse and complex. Technologies such as pumped hydro, compressed air energy storage, and thermal storage are gaining traction, particularly in regions with unique grid challenges or policy incentives.

Across Europe, hybrid energy storage systems are emerging that combine multiple storage types for optimized flexibility and performance. At the same time, falling battery costs and policy frameworks like the U.S. Inflation Reduction Act and the EU’s REPowerEU are driving record-level investments in utility-scale systems.

Companies are pushing for longer-duration storage, AI-based optimization, and modular solutions that integrate smoothly with renewable energy sources. These shifts are changing how energy is stored and when and where it’s used.

This article discusses 10 energy storage companies that are working on emerging solutions to support global energy needs.

Find out more about innovations, industry players, and factors that are changing the energy storage industry this year in this report. Fill out the form to get your copy of our exclusive energy storage trends report in your inbox:

1. Contemporary Amperex Technology Co., Limited (CATL)

CATL has deployed over 256 GWh of energy storage system capacity globally to date across 1,000+ energy storage projects. It has maintained a zero-accident record to date, according to CATL.

On its “Tech Day” event on April 21, CATL unveiled three battery technologies.

Next-Generation 587 Ah Energy Storage Cell

In June 2025, CATL unveiled its next-generation high-capacity energy storage battery cell—a 587 Ah cell engineered specifically for utility-scale applications. With an energy density of 434 Wh/L, this new cell marks a 10% improvement and can boost overall energy storage system density by up to 25%.

The product is developed after three years of research. It is compatible with 1,500 V PCS voltage and power ranges, as well as mainstream 20-foot containers. The total number of system components is reduced from 30,000 to 18,000, which simplifies the architecture and reduces the number of potential failure points.

The cell has passed stringent Chinese safety standards, showing no risk of fire or explosion under thermal runaway, overcharging, or puncture conditions.

Beyond technical improvements, the cell enhances lifecycle ROI by 5% due to superior energy density, system efficiency, and control over lifespan degradation. Already in mass production and delivery, this innovation further strengthens CATL’s leadership in global energy storage.

TENER Stack Energy Storage System

In May 2025, CATL introduced the TENER Stack, the world’s first 9 MWh ultra-large-capacity energy storage system, at ees Europe. Designed for large-scale industrial, grid, and data center applications, the TENER Stack addresses the growing demand for high-density, space-saving battery systems.

It uses CATL’s latest high-energy-density LFP cells with zero degradation over five years, delivering a 45% improvement in volume utilization and a 50% increase in energy density compared to standard 20-foot container systems.

This enables greater storage in smaller footprints, allowing a deployment like 800 MWh to require one-third fewer containers than traditional setups, reducing construction costs by up to 20%.

TENER Stack supports both centralized and string PCS architectures, offering flexibility in integrating with various AC-side systems. Its smart split-container design ensures each transport unit stays below 36 tonnes, complying with transport rules in 99% of global markets while cutting logistics costs by 35%.

The system features LFP chemistry, enhanced gas sensors, triple-layer insulation, and resilience to magnitude 9 earthquakes and Category 5 hurricanes. An overhead thermal management system (TMS) enhances cooling and reduces noise, making the unit suitable for even urban settings. This launch strengthens CATL leadership in long-duration, high-performance, and transport-friendly energy storage solutions.

Second-generation Shenxing Super-Fast Charging Battery

The second-generation Shenxing super-fast charging battery represents a notable advancement in lithium-ion technology. This battery boasts higher energy density and significantly reduced charging times, enabling EVs to achieve an impressive 520 kilometers (323 miles) of range with just five minutes of charging.

This performance marks a substantial improvement over its first-generation predecessor, which offered a range of 400 km with 10 minutes of charging.

Furthermore, the battery demonstrates robust performance even in cold weather, capable of charging from 5% to 80% within 15 minutes at a temperature of -10°C (14°F).

Freevoy Dual-Power Battery

The Freevoy Dual-Power Battery features a unique dual-core architecture with two energy zones, each utilizing separate cell chemistries tailored for different driving conditions. A key technological highlight is the “self-forming anode” technology employed in its long-distance zone, which eliminates the need for traditional graphite anode materials.

This innovation allows for significantly higher energy capacity within the same battery package space. As a result, it has increased energy density and peak ranges of over 1,500 kilometers (932 miles). The Freevoy battery is versatile and even suitable for use in commercial vehicles, ships, and even aircraft.

Naxtra Sodium-ion Battery

‘Naxtra’ is claimed to be the world’s first mass-produced sodium-ion battery. It marks a significant shift towards cost-effective and sustainable alternatives to lithium.

These batteries are designed to excel in extreme conditions, maintaining 90% energy delivery even at -40°C (-104°F). They also demonstrate high safety standards, as confirmed by rigorous tests that include multi-sided compression, drilling, nail penetration, and battery sawing. It performed well in all tests without fire or explosion.

CATL’s second-generation sodium-ion batteries aim to exceed 200 Wh/kg in energy density and can achieve up to 20,000 charge cycles with 70% capacity retention for longevity. Specifically, the Naxtra batteries offer an energy density of 175 Wh/kg, enabling EVs to travel up to 500 kilometers on a single charge. They can charge from 30% to 80% in just 30 minutes at -30°C and allow a car to maintain a highway speed of 120 km/h even with only a 10% charge. Each battery can be charged over 10,000 times and can support five million kilometers of driving.

Mass production of Naxtra sodium-ion batteries is scheduled to commence in two stages: 24V sodium-ion batteries for commercial vehicles are set to roll out in June 2025. For passenger cars, these batteries are expected to be available by December 2025.

Collaborations

CATL and Quinbrook to Build Advanced Long-Duration Battery Storage

In a major push for long-duration energy storage, Quinbrook Infrastructure Partners has joined forces with CATL to develop an 8-hour battery energy storage solution, effectively doubling the current industry standard.

The new system was designed in collaboration with Private Energy Partners, a Quinbrook affiliate. It will be deployed at multiple sites across Australia. These include Brisbane’s Supernode, the country’s largest battery energy storage campus. Other locations include industrial hubs in Gladstone and the Lansdown Eco-Industrial Precinct in Townsville.

The goal is to provide industrial users with a reliable method for running two full 8-hour shifts using only solar power. With plans to roll out over 3 GW of long-duration storage, Quinbrook sees this as a key step toward enabling 24/7 renewable energy use and stabilizing the power grid. This project will also integrate Quinbrook’s Quintrace platform to monitor and optimize carbon emissions.

Choco-Swap: Battery Swapping as Distributed Energy Storage Infrastructure

In December 2024, CATL took a transformative step toward redefining energy storage infrastructure by launching the Choco-Swap ecosystem. It is a standardized battery swapping solution designed for electric mobility and as a scalable, distributed energy storage network.

At the core of this initiative are the #20 and #25 standardized, swappable battery models, available in lithium-iron-phosphate (LFP) and nickel-manganese-cobalt (NMC) chemistries. These packs offer capacities ranging from 42 kWh to 70 kWh, enabling vehicle ranges of between 400 km and 600 km.

Each Choco-Swap station is also a grid-interactive energy storage node, featuring 14–30 battery compartments and achieving a 99.99% swap success rate in under 100 seconds.

CATL plans to build 30,000 battery swap stations. These will have a combined energy storage capacity of over 33.6 million kWh, plus an additional 1.12 billion kWh stored within the connected EVs. These stations integrate with cloud-based platforms for dynamic load balancing, enabling B2G (battery-to-grid) services such as peak shaving, frequency regulation, and intelligent off-peak charging.

By maximizing the use of renewable energy and stabilizing the grid, Choco-Swap stations function as distributed, intelligent energy storage systems. Nearly 100 partners across the automotive, finance, insurance, and e-commerce sectors are already on board with this initiative.

Strategic Partnership with Taiyuan Heavy Machinery Group (TZCO)

In October 2024, CATL entered a strategic partnership with Taiyuan Heavy Machinery Group Co., Ltd. (TZCO), a major player in China’s heavy machinery sector and one of the country’s top 500 industrial enterprises.

Under the agreement, CATL becomes TZCO’s preferred supplier of power batteries for its extensive range of construction and industrial machinery. This includes mining excavators, industrial cranes, and high-end hydraulic systems.

The collaboration aims to drive electrification across the heavy equipment sector, combining CATL’s cutting-edge battery technology with TZCO’s manufacturing scale and industry reach. This partnership also extends beyond machinery to energy storage systems and battery swapping technologies, with both parties committed to exploring new cooperation models.

National Electrochemical Energy Storage System Construction Project (Phase I)

On June 22, 2024, CATL announced its involvement in the National Electrochemical Energy Storage System Construction Project (Phase I).

With a total investment of approximately 3 billion yuan (around $415 million USD), the project will establish an “one center and four bases” model. It includes R&D facilities, grid-connected demonstration sites, and high-voltage fail-safe testing platforms. The goal is to develop large-capacity, high-safety, and high-reliability energy storage systems, alongside testing technologies and new industry standards for grid integration.

CATL is a core investor in the project. Its wholly-owned subsidiary, Xiamen Shizheng Energy Storage Technology Research Institute, is leading the construction and operations.

Read Related Article

2. Siemens AG

Siemens is renowned for integrating sophisticated Battery Energy Storage Systems (BESS) into national grids worldwide. It is also a pioneer in Compressed Air Energy Storage (CAES) and a leading force in Power-to-X technologies, particularly green hydrogen.

Hybrid Power Solutions

Siemens Energy Hybrid Power Solutions integrates multiple power sources, including renewable energy, energy storage, and traditional generators, to deliver reliable and efficient electricity. These solutions are designed to optimize energy production, decrease reliance on fossil fuels, and enhance energy resilience, particularly in remote and off-grid environments.

Battery Energy Storage Systems (BESS)

Siemens offers Battery Energy Storage Systems (BESS) for efficient and cost-effective energy storage. A notable product in this category is SIESTORAGE NEO, provided by Siemens Infrastructure.

The base configuration of SIESTORAGE NEO provides 184 kW of power with a capacity of 164 kWh. It is highly scalable, allowing expansion up to 368 kW of power and 656 kWh capacity, with extensive customization options. The system has a compact, space-saving design, with all components integrated into a single, robust housing, ensuring reliability in various locations.

SIESTORAGE NEO supports high-power charging on weak grid connections, stores self-generated energy, balances peak loads, offers smart and efficient load management, and provides power factor correction. It also incorporates features like time-of-use optimization, reactive power control, load following, ramp rate control, renewable time shift, and demand charge reduction.

Mechanical And Chemical Storage Systems

Siemens Energy’s portfolio encompasses mechanical storage systems, including Compressed Air Energy Storage (CAES) and Liquid Air Energy Storage (LAES).

The company also offers chemical storage solutions, including those for hydrogen and fuel cells, such as maritime fuel cell systems.

Thermal Storage Systems

The company also provides Thermal Storage Systems, which can be combined with mechanical solutions for mid-term industrial heat and electricity needs. Its ETES (Electric Thermal Energy Storage) technology uses low-cost volcanic rocks as storage material, offering significant cost advantages and economies of scale compared to lithium-ion battery systems.

Electrolyzers

As part of its Power-to-X solutions, Siemens Energy offers Electrolyzers. Its latest product line features a double-digit megawatt range in its Proton Exchange Membrane (PEM) electrolysis portfolio, with a modular design designed for large-scale industrial applications.

They also provide an integrated electrolyzer and heat pump solution that combines hydrogen production with waste heat utilization and cooling for the PEM electrolyzer.

Collaborations, Acquisitions, and Investments

Eaton And Siemens

On June 3, 2025, Eaton and Siemens Energy announced a strategic partnership aimed at accelerating the development of data centers with on-site power generation. The goal is to meet rising global demand for AI and cloud computing by providing energy systems that are independent of the grid. Their approach utilizes modular, standardized systems that enable data centers to be built and launched more quickly.

Siemens Energy will supply modular power plants generating 500 MW using efficient SGT-800 gas turbines. These systems are scalable and can run carbon-neutral once hydrogen becomes available. Optional emission-free grid connections will further boost sustainability.

Eaton will provide key electrical components and engineering support, including switchgear and UPS systems, to ensure a reliable power flow from the source to IT equipment.

This partnership aims to cut the time needed to build and launch a data center by up to two years. It also provides operators with more flexibility in selecting energy sources and complying with regional regulations. In addition to reducing CO₂ emissions by 50%, this model can drive faster revenue generation compared to traditional methods.

Green Hydrogen Collaborations

As part of its ongoing commitment to Power-to-X, Siemens Energy, through its joint ventures and partnerships, is planning and developing new large-scale green hydrogen production facilities:

- Siemens Energy collaborated with the Sarawak government (Malaysia) to increase its hydrogen production.

- Siemens has partnered with TURN2X to support the production of renewable natural gas (RNG) by becoming a preferred supplier and technology partner. Siemens will contribute its Xcelerator portfolio to optimize process automation, enhance plant operations through digital twins, and provide energy management tools. It will also support facility expansion with standardized solutions and improved cybersecurity.

- Siemens has partnered with Guofu Hydrogen, a leading supplier of integrated hydrogen solutions, and RCT GH Hydrogen, a Germany-based provider of hydrogen systems, to accelerate the global production of green hydrogen. As part of the collaboration, Siemens will become the preferred supplier and technology partner for electrolyzers and hydrogen production systems. The partnership focuses on three main areas: developing electrolyzers and systems, equipping new manufacturing facilities in Germany, and constructing new hydrogen production plants.

Siemens will contribute its Xcelerator portfolio, offering industrial automation, electrification, and digital solutions to improve efficiency and scalability in electrolyzer manufacturing.

Upcoming Product, Facility related to Energy Storage

Integrated Onsite Power Solutions for Data Centers

Stemming from their 2025 collaboration with Eaton, Siemens Energy is focusing on the development and deployment of integrated onsite power solutions for data centers.

Global AI Manufacturing Technologies R&D Center

Siemens announced a CAD$150 million investment to establish a Global AI Manufacturing Technologies R&D Center for Battery Production in Canada. This five-year initiative, based at Siemens Canada’s headquarters in Oakville, will focus on advancing AI technologies for battery and electric vehicle (EV) production. It has additional sites in Toronto and Kitchener-Waterloo.

The center will leverage AI, edge computing, machine vision, digital twins, and cybersecurity to enhance efficiency, quality, and sustainability in the battery manufacturing process. Key goals include improving battery quality, reducing waste, and boosting recycling and circularity.

Supported by both the Government of Canada and the Government of Ontario, the center will also collaborate with universities and industry partners.

3. ABB

ABB is a global technology leader in electrification and automation. The company is strengthening its position in the energy storage market by expanding its grid-forming energy storage systems and energy optimization software portfolio.

BESS-as-a-Service

ABB’s flagship offering is the BESS-as-a-Service, a flexible, zero-CapEx solution designed to accelerate the transition to clean, resilient, and affordable energy.

The service encompasses necessary hardware, software, and lifecycle support. ABB manages the deployment, maintenance, and optimization of the system, enabling businesses to focus on their core operations while enhancing energy efficiency, resilience, and long-term sustainability. It works with any type of battery technology, offering customers the flexibility to leverage the latest innovations without being tied to a single system.

It also provides the benefit of transitioning the financial model from a capital expenditure approach to a predictable operational expenditure model through a quarterly service fee.

ABB conducts feasibility assessments as a prerequisite to deployment, ensuring that customers achieve net financial benefits from the outset.

Hybridized Energy Storage System (HESS) and Battery Energy Storage System (BESS) Applications

ABB offers Hybrid Energy Storage Systems (HESS) and Battery Energy Storage Systems (BESS) that utilize battery cells and ultracapacitor technologies for services.

These solutions address critical energy challenges, including EV fast-charging infrastructure, peak shaving for commercial buildings, power reliability for manufacturing, and optimizing the integration of renewable energy for industrial sites.

Collaborations, Partnerships, Acquisitions, and Investments

Strategic Minority Investment in Hesstec

On June 5, 2025, ABB announced a strategic minority investment in HESStec, a Spanish energy storage company specializing in hybridized energy storage systems (HESS) and battery energy storage systems (BESS).

Through this partnership, ABB aims to expand its capabilities in grid-forming energy storage and energy optimization software, supporting its recently launched BESS-as-a-Service model. As part of its broader venture capital strategy, ABB sees this investment as a key move to strengthen its innovation ecosystem and accelerate the transition to net-zero energy infrastructure.

Partnership with GridBeyond

In May 2025, ABB announced a partnership with GridBeyond, an AI-driven energy management platform provider. This collaboration focuses on optimizing the performance of ABB’s Battery Energy Storage System (BESS) as a service (BESS-as-a-Service) assets. GridBeyond’s platform will enable real-time energy optimization, demand-side response participation, and access to new revenue streams in global energy markets for ABB’s BESS deployments. Last year, ABB made a strategic minority investment in GridBeyond to expand its energy storage solution portfolio.

Collaboration with Tallarna

ABB and GridBeyond will also collaborate with Tallarna, a climate tech and finance platform. This partnership, announced in May 2025, will leverage Tallarna’s data analytics software, insurance solutions, and financing expertise to mitigate the risks associated with Battery Energy Storage System (BESS) projects. Tallarna’s tech will also be used to manage and analyze the finances of these projects.

Read Related Article

4. Sumitomo Electric Industries

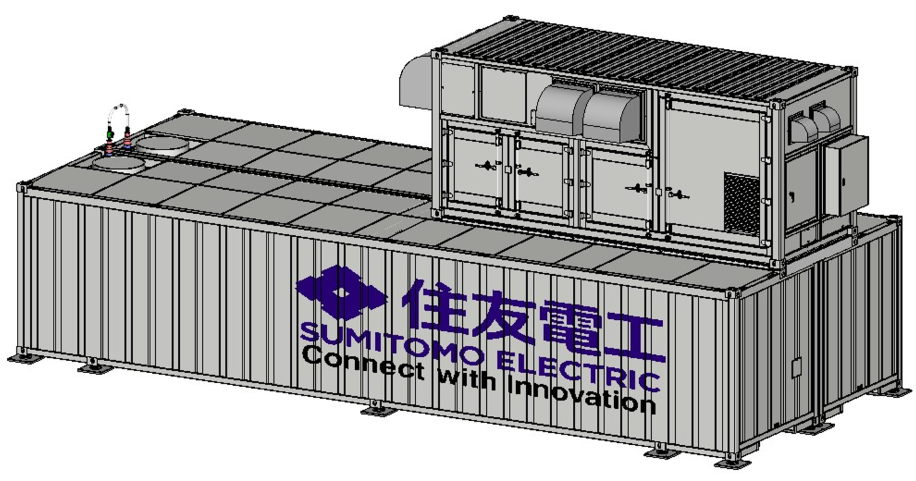

Sumitomo Electric Industries has been at the forefront of Vanadium Redox Flow Battery (VRFB) research since 1982. Its VRFB systems with over 7 years of stable operation in San Diego represent the longest-running VRFB installation in North America.

Vanadium Redox Flow Batteries (VRFB)

Sumitomo VRFB systems are highly flexible. Their power output can be increased by adding more cell stacks, and energy capacity can be expanded by increasing the volume of electrolyte or the tank size. They are available in standard container sizes (20ft, 30ft, 40ft, 53ft) with varying energy capacities (750 kWh – 2,500 kWh) and discharge durations (3 – 10+ hours).

An example 1,000kW * 5h system (5,000kWh) demonstrates an AC-AC efficiency of over 70%. The technology supports unlimited charge and discharge cycles with minimal degradation, ensuring a long operational life. The systems are designed for a 20-year lifecycle.

The operational Depth of Discharge (DOD) ranges from 0% to 100%, and the device operates within ambient temperatures ranging from -5℃ to 40℃. The system enables real-time, accurate monitoring of the state of charge (SOC) and provides easy operation.

The electrolyte used in this VRFB is non-flammable, and all components are made of flame-retardant materials, resulting in an extremely low fire risk. The system is not classified as hazardous under fire safety regulations.

Sumitomo’s VRFBs offer high flexibility for various applications, capable of both fast response (e.g., < 100 msec AC response time for -100% to 100% output) and long-duration discharge within a single system.

Recent Collaborations, Partnerships, Acquisitions, and Investments

Tax Equity Investment in Solar PV Plus Battery Energy Storage Projects

On June 26, 2024, Sumitomo Corporation of Americas (SCOA), announced a tax equity investment in a portfolio of solar photovoltaic (PV) plus battery energy storage projects, led by Pacifico Power. This investment includes six projects totaling 27 MW of solar PV and 25 MWh of battery storage in Massachusetts and California, designed to serve approximately 4,000 U.S. households.

The portfolio also features four behind-the-meter projects in California aimed at supporting commercial and industrial (C&I) customers by integrating renewable energy, reducing costs, and enhancing reliability.

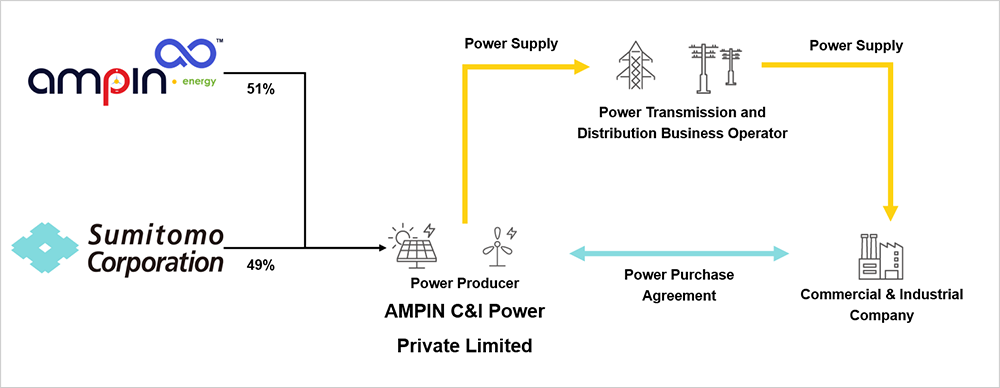

Sumitomo’s Entry into the Indian Market in Partnership with AMPIN Energy Transition

Sumitomo Corporation has partnered with AMPIN Energy Transition to establish a renewable energy development and supply company in India, marking its first entry into the country’s corporate Power Purchase Agreement (PPA) market.

The newly formed company, AMPIN C&I Power Private Limited, based in New Delhi, will focus on developing renewable energy sources. It includes solar and wind power, with a total project cost of approximately ¥ 100 billion. This collaboration aligns with India’s renewable energy goals, including achieving 50% renewable energy generation by 2030 and net-zero emissions by 2070.

Sumitomo joint venture with Perennial Power Holdings and CEP Solar, LLC

Sumitomo Corporation of Americas (SCOA) has formed a joint venture with Perennial Power Holdings and CEP Solar, LLC to develop renewable energy projects in Virginia, United States. This partnership aims to commercialize a portfolio of solar and battery storage assets exceeding 1.5 GW, with construction set to begin in late 2025.

The joint venture will focus on delivering clean energy projects across the Commonwealth of Virginia, an area known for its rapidly growing IT infrastructure and data center clusters. This initiative aligns with Sumitomo’s strategic goal to expand its presence in one of the fastest-growing power markets in the U.S.

Upcoming Products & Facilities

Nagasu Energy Storage Facility in Kumamoto, Japan

Sumitomo Electric’s redox flow battery has been selected for a power system stabilization project by SHIN-IDEMITSU Co., Ltd. (IDEX). The RF battery will be installed at the Nagasu Energy Storage Facility in Tamana District, Kumamoto Prefecture, with a capacity of 8,000 kWh (2,000 kW × 4 hours). The project is set to be completed by October 2026.

This is the first RF battery project to be approved under Japan’s Ministry of Economy, Trade and Industry (METI) and the Agency for Natural Resources and Energy’s subsidy program for grid-scale energy storage. The project aims to stabilize the supply of renewable energy in regions experiencing high solar radiation levels.

5. Air Liquide

Air Liquide is a global leader in industrial gases, technologies, and services, operating across 60 countries. Its Global Markets & Technologies (GM&T) business unit is strategically focused on supporting the energy transition and deep tech markets.

The company has installed more than 200 hydrogen stations worldwide. It also manages the entire value chain of biomethane, from production to distribution, with 29 biomethane production units globally.

Air Liquide’s energy storage strategy is heavily oriented towards hydrogen and carbon capture and storage.

Hydrogen Solutions

Air Liquide offers comprehensive Hydrogen (energy) solutions, covering various aspects of the hydrogen value chain:

- Electrolyzers: It is involved in large-scale electrolyzer projects for producing renewable and low-carbon hydrogen. Air Liquide has a joint venture with Siemens Energy as a gigafactory in Berlin that manufactures Proton Exchange Membrane (PEM) electrolysis stacks using advanced robotics.

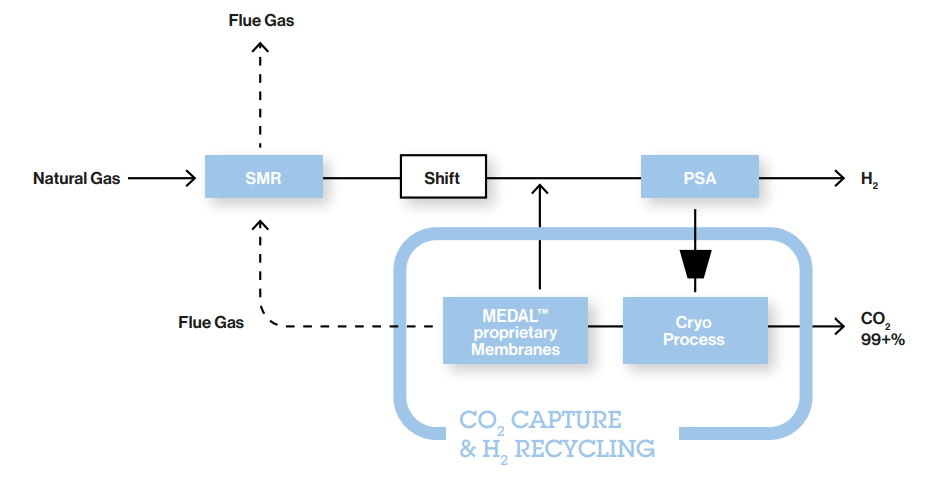

- Autothermal Reforming (ATR) Technology: Air Liquide utilizes its proprietary ATR technology, combined with carbon capture (achieving up to a 99% capture rate), for industrial-scale low-carbon hydrogen and ammonia production.

- Cryocap™ CO₂ Cold Capture System: This cryogenic process captures CO₂ released during hydrogen production, significantly reducing emissions. Its first industrial deployment occurred at Air Liquide’s largest steam methane reforming hydrogen production unit in Port-Jérôme, France.

- Hydrogen Liquefaction: The company offers solutions for hydrogen liquefaction, serving both industrial and mobility applications.

- Ammonia Cracking Technology: Air Liquide is enhancing its hydrogen solutions portfolio by developing technology to convert ammonia into hydrogen

It also designs and manufactures production units that purify biogas derived from agricultural, household, or industrial waste. This biomethane is then utilized for clean mobility, electrical power generation, and heating applications.

Cryogenics

Air Liquide offers extensive expertise in mechanical cold production, gas liquefaction, and the storage and distribution of cryogenic fluids at extremely low temperatures. The company supports scientific research and space exploration with its cryogenic solutions. Its Turbo-Brayton cryogenic equipment is utilized explicitly in maritime transport for boil-off gas reliquefaction, with nearly 70 units ordered in 2024.

Recent Collaborations and Investments

Air Liquide Partnership with TotalEnergies

Air Liquide has partnered with TotalEnergies to decarbonize TotalEnergies’ refineries in Northern Europe by producing green hydrogen using renewable power. The two companies have signed agreements to develop projects in the Netherlands, leveraging power from the OranjeWind offshore wind farm, co-developed by TotalEnergies and RWE.

These projects aim to produce 45,000 tons of green hydrogen per year. The aim is to reduce CO2 emissions by up to 450,000 tons annually across TotalEnergies’ refineries in Belgium and the Netherlands. The partnership includes a joint venture to construct a 250 MW electrolyzer near the Zeeland refinery, which will produce up to 30,000 tons of green hydrogen annually. The electrolyzer is expected to be operational by 2029.

Additionally, TotalEnergies has signed a tolling agreement for 130 MW of green hydrogen production at the ELYgator electrolyzer project in the Netherlands.

Both companies are already partners in a jointly owned venture, TEAL Mobility. It operates a network of 100 hydrogen stations for heavy vehicles in Europe.

EU Decarbonization Projects

The company has also received substantial EU Grants for Decarbonization Projects:

- A €160 million grant for the d’Artagnan CO2 infrastructure project in Dunkirk, France.

- A €220 million grant, in collaboration with Cementir Holding Group, for their ACCSION carbon capture and storage project in Denmark.

- Air Liquide has been awarded a €110 million grant from the European Innovation Fund for its ENHANCE project in the Port of Antwerp-Bruges, Belgium. The project aims to produce and distribute low-carbon and renewable hydrogen using renewable ammonia as a feedstock. As part of this initiative, Air Liquide will construct and operate a large-scale ammonia cracking plant and a hydrogen liquefier, making it the first industrial-scale project of its kind in Europe.

Investment to Expand Production Capacities and Pipeline Network in the US

Air Liquide is making a significant investment of approximately $150 million to expand production capacities and its pipeline network in the US. It aimed at supplying oxygen to LG Chem’s battery plant for electric vehicles in Tennessee.

Investment in Hydrogen Supply Chain

Air Liquide is investing €50 million to develop a hydrogen packaging and delivery supply chain along the Seine Axis. This will support the growth of low-carbon mobility in the Normandy and Île-de-France regions. The new packaging site will be supplied by the Air Liquide Normand’Hy electrolyzer, a 200 MW renewable hydrogen facility currently under construction.

Around 25% of the electrolyzer’s output will be dedicated to transportation. It will be enough to fuel approximately 500 hydrogen trucks or 10,000 light vehicles. This supply will support a rising fleet of hydrogen taxis, utility vehicles, buses, and trucks, including those operated by HysetCo, with whom Air Liquide has a long-term hydrogen supply contract. The remaining 75% of the plant’s hydrogen will serve industrial customers in Normandy, such as TotalEnergies’ Gonfreville refinery.

This initiative builds on Air Liquide’s existing hydrogen infrastructure in the region, which includes production units at Port-Jérôme and Gonfreville.

Upcoming Products & Facilities

Air Liquide has announced two major upcoming electrolyzer projects in the Netherlands, aimed at significantly boosting the production of renewable and low-carbon hydrogen in Europe.

The first, called ELYgator, is a 200 MW electrolyzer to be built in Maasvlakte (Rotterdam). It will supply hydrogen to TotalEnergies’ industrial platform under a long-term contract, while also supporting industrial and heavy mobility sectors across the Netherlands and neighboring countries.

The second project, currently under study, involves a 250 MW electrolyzer in the province of Zeeland, developed through a joint venture between Air Liquide and TotalEnergies to supply the TotalEnergies refinery there.

6. QuantumScape

QuantumScape is a U.S.-based energy storage company in the development of next-generation solid-state lithium-metal batteries. Its solid-state technology eliminates the need for a liquid electrolyte and graphite anode. This enables lighter and more efficient battery designs that could significantly extend EV range and performance.

QuantumScape offers anode-less cell design, which forms the lithium-metal anode in situ during the first charge. This simplifies manufacturing and boosts energy density.

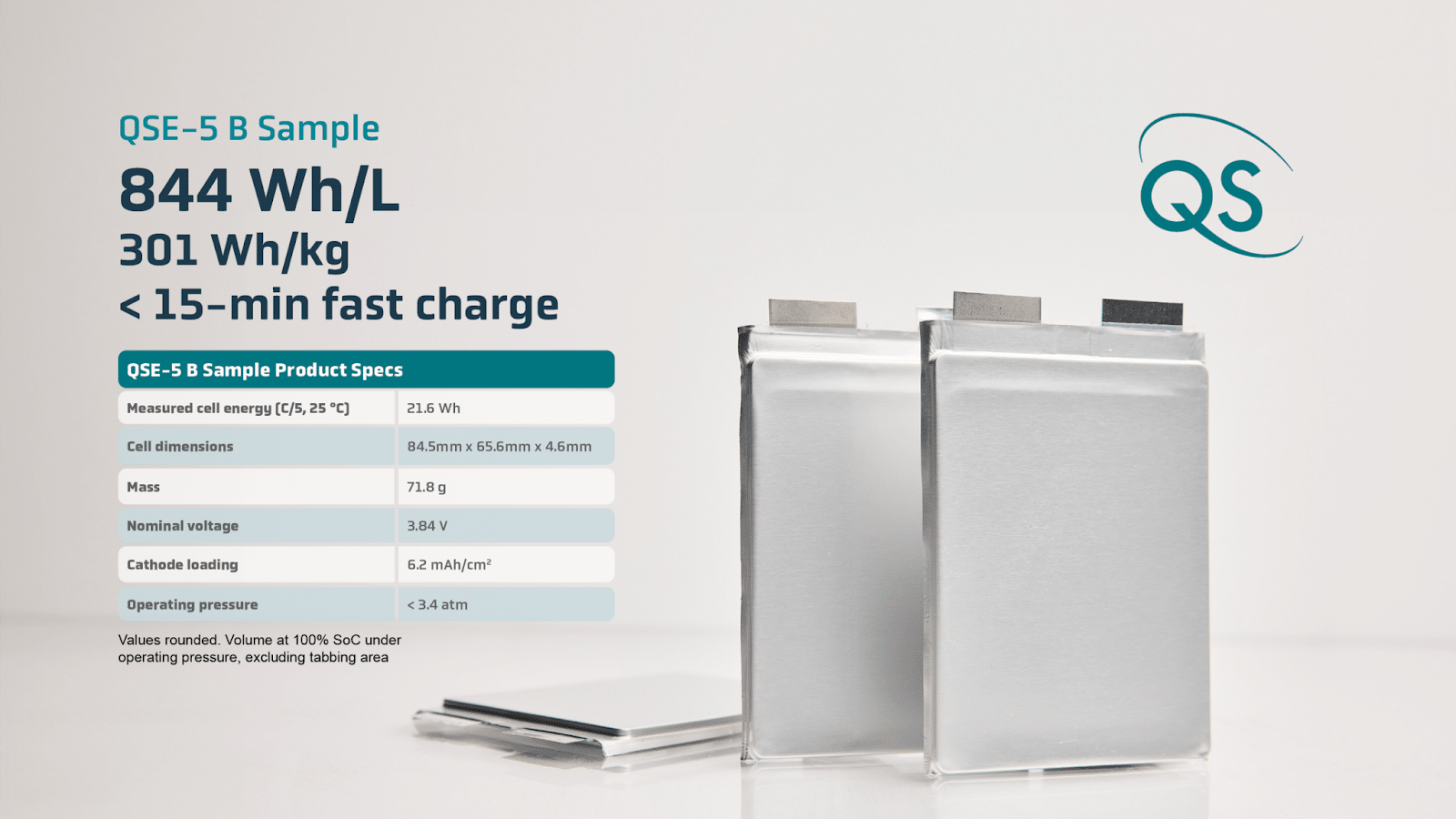

QSE-5 Cells: QuantumScape’s First Commercial Battery Product

The QSE-5 cells mark QuantumScape’s first planned commercial battery product, built on its anode-less solid-state lithium-metal battery architecture. These cells aim to deliver an exceptional combination of energy density, fast charging, power output, and safety. Specifically, the QSE-5 targets an energy density of 800–1,000 Wh/L, significantly exceeding that of conventional lithium-ion batteries (~700 Wh/L), potentially extending EV ranges to 400–500 miles.

Thanks to the absence of a conventional anode, the QSE-5 enables 10–80% fast charging in under 15 minutes, as lithium plates directly onto the current collector during charging, bypassing the diffusion bottlenecks found in traditional designs.

The cells incorporate QuantumScape’s proprietary solid ceramic separator. It’s a nonflammable and thermally stable material that improves safety and prevents dendrite formation, and supports high current densities.

Early prototypes, including a 24-layer A0 version, have demonstrated over 1,000 full cycles with 95% energy retention, which equates to approximately 300,000 miles of EV driving without significant capacity loss.

The QSE-5 also supports compatibility with multiple cathode chemistries, such as Nickel-Manganese-Cobalt (NMC) and Lithium-Iron-Phosphate (LFP), providing flexibility across various application types.

Designed with scalability in mind, QSE-5 cells leverage a continuous-flow manufacturing process using earth-abundant materials. This helps reduce costs and accelerate commercial readiness.

Recent Collaborations, Acquisitions, and Investments

Murata Manufacturing Collaboration

In April 2025, QuantumScape and Murata Manufacturing Co. announced the first phase of an agreement to explore high-volume manufacturing of ceramic film for QuantumScape’s solid-state battery technology. Murata’s expertise in high-precision ceramics manufacturing complements QuantumScape’s proprietary solid ceramic separator, a critical component enabling the use of pure lithium-metal anodes. This collaboration is part of QuantumScape’s strategy to establish a global ecosystem that supports the commercialization of its battery technology.

Collaboration Agreement with Volkswagen’s PowerCo

In July 2024, QuantumScape entered into a non-exclusive licensing agreement with PowerCo, Volkswagen Group’s battery subsidiary. This partnership enables PowerCo to manufacture up to 40 GWh per year of battery cells utilizing QuantumScape’s technology, with the option to expand to 80 GWh annually.

The agreement includes royalty payments and a $130 million prepayment from PowerCo to QuantumScape. The collaboration aims to accelerate the industrialization of QuantumScape’s solid-state batteries for integration into Volkswagen’s electric vehicles.

Strategic Blueprint for 2025

QuantumScape’s strategic blueprint for 2025 is centered on three key elements: collaborations, real-world technology implementation, and R&D.

The company is collaborating with select original equipment manufacturers (OEMs) to embed QSE-5 B-sample cells into prototype vehicles. This will help collect real-world performance, fast charging, and energy retention feedback. It is also building a global ecosystem of suppliers, manufacturers, system integrators, and licensing partners to scale its ceramic-separator, anode-less cell technology. Meanwhile, ongoing R&D will refine energy density, charging speed, and cycle life, guided by a multi-year roadmap targeting next-generation cell formats and materials.

The company plans to spend approximately $65 million in capital expenditures in 2025 and an additional $45 million in 2026 to support the demand for its solid-state battery cells.

To support its operations and expansion, QuatumScape requested an extension of the Sales and Use Tax Exclusion (STE) award’s initial term from June 21, 2025, to June 21, 2027. This extension was necessary to accommodate a technology process change, specifically modifying the production process for its “Raptor and Cobra” separators.

Read Related Article

7. Itron

Itron is a globally recognized leader in energy, water, smart city, Industrial IoT (IIoT), and intelligent infrastructure services. It is serving over 8,000 customers across more than 100 countries.

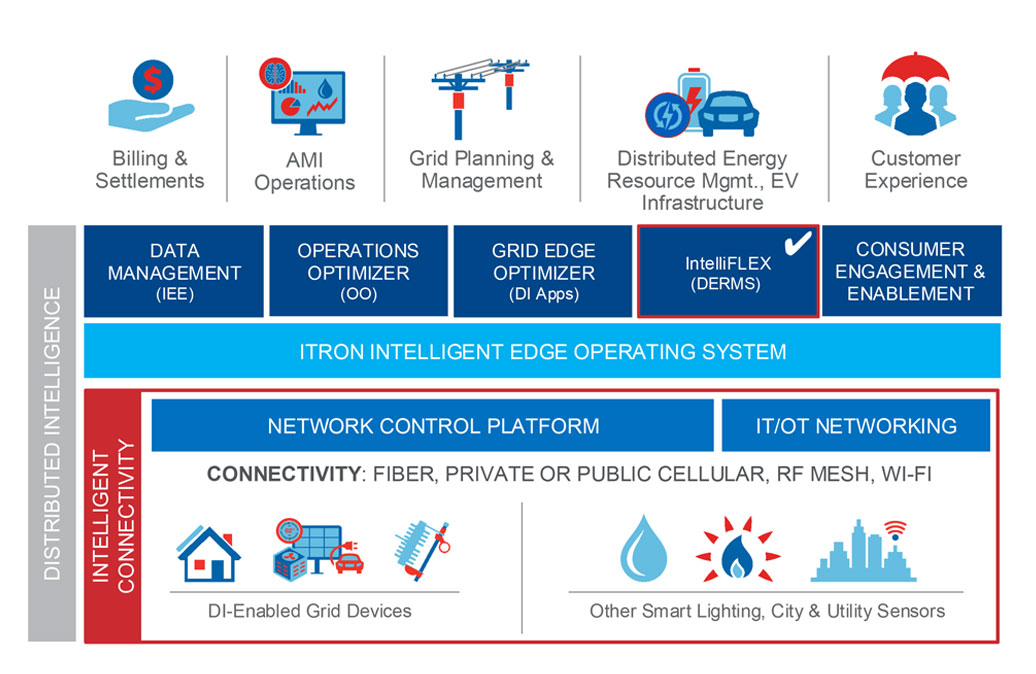

The company’s energy storage solutions are centered around the integration and management of distributed energy resources (DERs) through advanced grid-edge technologies. Its approach focuses on the real-time coordination, optimization, and control of various DERs to enhance grid reliability and efficiency. This includes batteries, electric vehicles (EVs), and flexible loads attached to the grid.

IntelliFLEX Suite

IntelliFLEX is Itron’s grid-edge Distributed Energy Resource Management System (DERMS) designed to provide real-time visibility and control over DERs. It integrates a broad ecosystem of flexible loads, including solar panels, load control switches, smart thermostats, batteries, and EVs.

The system leverages Advanced Metering Infrastructure (AMI) and Distributed Intelligence (DI) to facilitate real-time DER coordination, automation, and granular grid awareness. This supports faster, localized decision-making, improved outage response, and reduces integration costs by 30% compared to alternative solutions. The solution has a demonstrated track record, managing 3 million DER devices for 30 utilities across the U.S.

The company also offers demand response solutions that bridge traditional programs with advanced DER technologies. The platform supports a wide range of devices, including load control switches, smart thermostats, grid-interactive water heaters, and battery storage systems.

Recent Collaborations, Acquisitions, and Investments

In May 2025, Itron introduced the Solar Battery Access Point (also called Solar Battery AP). It is a new solar-powered, battery-operated device designed to improve network connectivity for gas and water utilities. This solution enables utilities to extend their Advanced Metering Infrastructure (AMI) in areas where traditional mesh networks or infrastructure, such as towers and poles, are unavailable or too expensive.

The device features a rechargeable power management system powered by an integrated solar panel, eliminating the need for external power sources. It can be mounted directly on utility-owned assets, lowering deployment and maintenance costs.

Additionally, this device has a lifespan of up to 20 years and low-latency mesh network capabilities. The Solar Battery AP offers a flexible and cost-effective solution to enhance connectivity and support utilities in transitioning from Automatic Meter Reading (AMR) to Advanced Metering Infrastructure (AMI) systems.

Collaboration with Tesla Inc. and Xcel Energy

Itron is engaged in a collaboration with Tesla Inc. and Xcel Energy to deploy an advanced Virtual Power Plant (VPP) in Colorado. This initiative, announced on March 20, 2025, is an extension of Itron’s ongoing work with Xcel Energy to manage DERs

Itron’s IntelliFLEX Aggregator DERMS solution directly integrates with Tesla’s battery storage platform (Tesla Powerwall home batteries). This will enable Xcel Energy to manage customer batteries during peak energy demand periods, thereby stabilizing the electric grid. This “Renewable Battery Connect” program allows various DERs to function as a single “virtual” power plant.

Collaboration with Microsoft

Itron collaborated with Microsoft to integrate generative AI into its Intelligent Edge Operating System (IEOS), aiming to simplify how utilities access and use data. By embedding Microsoft’s Copilot AI, utilities can ask natural language questions and receive immediate insights without needing technical expertise. This AI-enabled platform, built on the Microsoft Azure OpenAI Service, will support tasks such as customer consumption analysis, data quality improvement, and cross-departmental queries. It will help utility operators analyze electricity, gas, water, and distributed energy data more efficiently. The integrated system is expected to launch globally in Q2 2025..

Collaboration with Schneider Electric

Itron, Schneider Electric, and Microsoft have partnered to enhance grid visibility and control at the distribution level. Their collaboration integrates Itron’s distributed intelligence (DI) meters, Schneider Electric’s Advanced Distribution Management System (ADMS), and Microsoft’s AI-driven cloud platform. The aim is to deliver real-time, low-latency data exchange between the grid edge and utility control centers.

This combined solution enables utilities to manage power flow, optimize voltage, and handle behind-the-meter distributed energy resources (DERs), such as EV chargers and solar panels, without relying on customer broadband. It also enables key use cases, such as transformer-to-meter mapping, improved load flow modeling, better voltage and VAR optimization, and more accurate DER planning. The solution is expected to roll out in North America by the end of 2025.

Acquisition of Elpis Squared

Itron acquired Elpis Squared in March 2024 to strengthen its Grid Edge Intelligence portfolio and accelerate its efforts in supporting utilities during the energy transition.

Elpis Squared offers software solutions for utility grid planning, operations, and engineering. Through this acquisition, Itron gains access to Elpis Squared’s RE|Grid Suite, which includes tools like Model Validator, System Planner, and Power Analyzer. These tools, combined with Itron’s advanced metering and high-resolution grid edge data, improved grid modeling accuracy, scenario planning, asset, and risk management. The integrated solutions are expected to roll out by late 2024.

Collaboration with PG&E

Itron and Pacific Gas and Electric Company (PG&E) are working together to make home EV charging more affordable and accessible through the EV Connect program. This pilot initiative utilizes Itron’s distributed intelligence technology to control EV charging in real-time, directly from the customer’s electric meter.

By doing so, it avoids the need for costly panel and service upgrades, often required to install faster Level 2 chargers, especially for homes with 100-amp service. Instead of relying on cloud-based updates, the program enables on-meter coordination with EV chargers to manage energy use within safe grid and home limits. The pilot, launched in early 2025, is to serve up to 1,000 residential customers, with plans to expand later in the year.

8. Highview Power

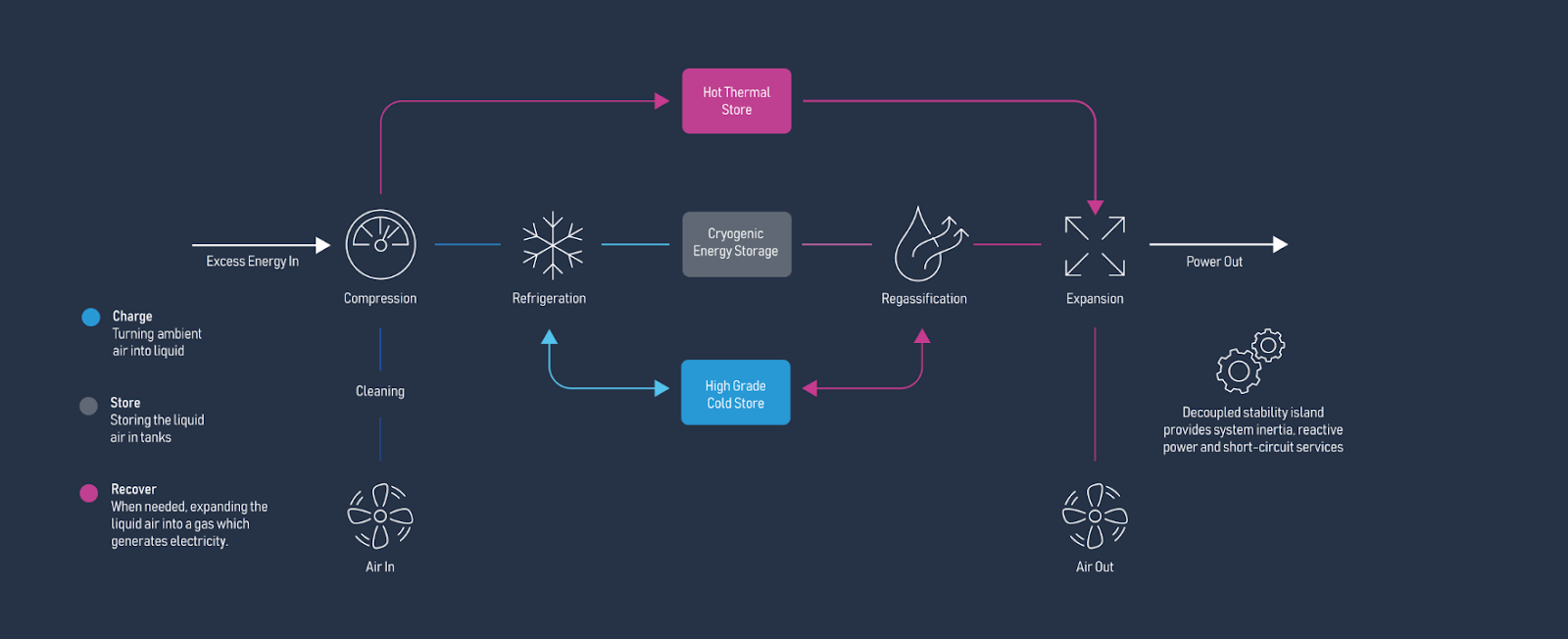

Highview Power is a leading provider of long-duration energy storage (LDES) technology. The company is actively developing large-scale energy storage facilities, such as the Hunterston project in the UK. Its exclusive focus on Liquid Air Energy Storage (LAES) addresses the requirement for long-duration storage without relying on batteries.

The company created the world’s first LAES Power demonstration plant at the Pilsworth landfill waste management site close to Manchester in the UK. It has been operational since 2018.

CRYOBattery™

HighView Power’s Liquid Air Energy Storage (LAES) system, branded as the CRYOBattery™, is a large-scale, long-duration energy storage solution that uses liquid air as the storage medium.

Unlike typical LAES setups, HighView’s system integrates advanced thermal and cold energy recovery technologies to improve round-trip efficiency. It operates using standard industrial equipment, such as compressors, heat exchangers, and expanders, making it modular and scalable up to hundreds of megawatt-hours.

The system is capable of delivering multiple grid services, including frequency regulation, voltage support, and black start capability. Designed for 10+ hour discharge durations, the CRYOBattery™ is particularly suited for supporting renewable integration and grid stability.

The capabilities of HighView Power’s LEAS technology are visible in their projects and LEAS plants they set around the world.

Energy Storage Projects and Collaborations

Funding Milestone

In June 2024, Highview Power secured a significant £300 million investment to advance its long-duration energy storage (LDES) programme. This brings the company’s total raised capital to £377 million, including a £70 million contribution from Centrica.

The funding round, supported by key players such as the UK Infrastructure Bank (UKIB), Centrica, Sumitomo, Rio Tinto, Goldman Sachs, KIRKBI, and Mosaic Capital, will fuel the development of a multi-billion-pound portfolio of LAES (liquid air energy storage) facilities aimed at strengthening the UK’s clean energy grid and meeting its 2030 net zero targets.

Hunterston LAES Plant – Scotland

The first of Highview’s four new 2.5 GWh LAES facilities will be located at the Peel Ports site in Hunterston, North Ayrshire, Scotland. Built in two phases—initial grid connection and grid stability works, followed by full LAES deployment—the facility will store surplus wind and solar energy and power up to 650,000 homes for over 12.5 hours. The project is part of a broader strategic rollout under the UK government’s “cap and floor” support scheme, designed to boost national decarbonisation goals.

Carrington Plant – Greater Manchester

Highview Power is also progressing its 300 MWh energy storage and grid stability facility at Carrington, near Manchester. It is scheduled to become operational in 2026. The Carrington facility is foundational to the UK’s LDES push and will serve as a benchmark for future large-scale grid storage projects. It also features in the first-of-its-kind deployment of Highview’s patented system innovations, which aim to participate in National Grid’s Enhanced Frequency Response tenders.

Three Additional UK LAES Plants

Beyond Hunterston and Carrington, Highview Power plans to establish three more 2.5 GWh plants—two in England and another in Scotland—by 2030. Each plant will feature a 40-year lifespan, 100% sustainable energy storage capabilities, and provide power to hundreds of thousands of homes. Together, all four new sites will add 10 GWh of storage capacity, surpassing the UK’s current battery storage levels and contributing over 10% toward the Future Energy Scenarios (FES) LDES targets.

Australia: Northern Territory Projects

In Australia, Highview Power is developing two renewable energy projects in the Northern Territory. The first is a 90 MW, 10-hour storage facility on the Katherine-Darwin network. The other one is a 30 MW, 12-hour facility near the Owen Springs Power Station outside Alice Springs. These projects integrate solar power with Highview’s proprietary Liquid Air Energy Storage (LAES) technology to provide a stable, base-load renewable energy supply. They align with the Territory’s goal to reduce carbon emissions by 50% by 2030.

Japan: Hiroshima LAES Demonstration

In Japan, Highview Power is collaborating with Sumitomo Heavy Industries and Hiroshima Gas to develop a 5 MW, 4-hour LAES facility in Hatsukaichi, Hiroshima. This project integrates LAES technology with an external cold source from an adjacent liquefied natural gas (LNG) plant, demonstrating the adaptability of LAES in various industrial contexts. Commercial operation was planned for 2024, marking a significant step in demonstrating LAES’s viability in Japan’s energy landscape.

9. Generac Holdings Inc.

Generac offers power generation equipment, energy storage systems, energy management devices, and solutions for residential, light commercial, and industrial markets.

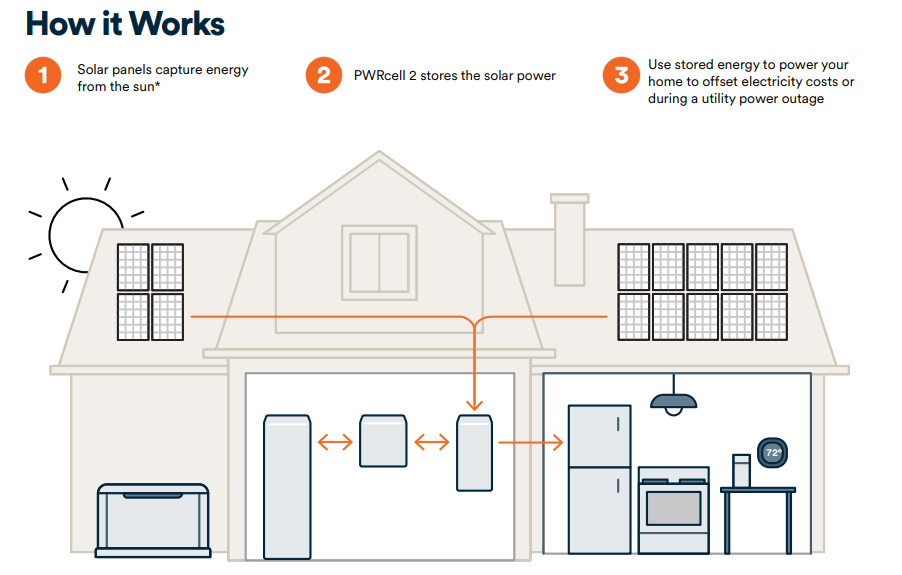

PWRcell Energy Storage Systems is the key product line of Generac Holdings:

PWRcell Modular System

This system includes lithium batteries, a battery storage enclosure cabinet, a hybrid solar inverter, and the PWRview app for monitoring. It is customizable and can be upgraded with additional battery modules as energy requirements change, expanding to 40 kWh of battery storage, providing 34.2 kWh of usable power at 80% discharge.

Hybrid Inverter: Each single-phase hybrid inverter can handle up to 10kW of PV DC solar input and deliver up to 8kW continuous AC output power, with a maximum AC output of 10kW. It provides up to 10 kW of surge power, sufficient to start heavy loads such as well pumps and air conditioners.

Battery Modules: The modular PWRcell battery can be configured to a maximum of 17.1 kWh in each enclosure. Connecting two enclosures allows for up to 35 kWh of usable electricity. The battery type is Lithium-Ion, with a nameplate energy of 14.4 kWh and usable capacity of 11.52 kWh at 80% Depth of Discharge (DOD). Round-trip efficiency is 96.5%.

Next-Generation PWRcell Energy Storage Products (PWRcell 2 and PWRcell 2 MAX)

Generac unveiled its next-generation PWRcell Energy Storage Products at RE+ on September 10, 2024, introducing the PWRcell 2 Home Energy Storage System product series, featuring PWRcell 2 and PWRcell 2 MAX.

- PWRcell 2: Delivers 18 kWh capacity in a single cabinet and 10 kW max continuous power, sufficient to start most single loads, including a 5-ton A/C unit during an outage. It will be available by the end of 2024.

- PWRcell 2 MAX: Will feature 11.5 kW max continuous power at launch, with the capability to start loads greater than 200A LRA. It offers higher efficiency and a broader operating temperature range. The PWRcell 2 MAX is expected to debut in the second half of 2025.

Alongside these launches, Generac continues to expand its clean energy offerings, including the L2 EV Charger, which further supports smart, sustainable home energy management.

New Products Designed for the Data Center Market

Generac has expanded its energy portfolio with a new range of emergency standby generators. These are tailored for the growing needs of data centers, including hyperscale, colocation, enterprise, and edge facilities.

The new lineup includes five generators ranging from 2.25 MW to 3.25 MW. These generators feature Baudouin M55 engines, Deep Sea G8601 controllers, and Marathon DataMAX alternators. Each component is designed to meet the high-performance, low-emission, and reliability standards required by the data center industry.

Designed for scalability and integration, these systems come with high ambient cooling, redundant starting systems, modular power capabilities, and configurable circuit breakers.

Generac also provides custom packaging and aftertreatment solutions, reinforcing its role as a dependable energy partner amid rising power demands and grid instability.

Recent Collaborations, Acquisitions, and Investments

Acquisition of Ageto

In August 2024, Generac Power Systems acquired Ageto, a company specializing in microgrid controllers for the commercial and industrial (C&I) market. Ageto’s technology enables the seamless integration, optimization, and management of various distributed energy resources.

This acquisition strengthens Generac’s position in the microgrid and energy storage space. Both companies had worked together since 2021 to incorporate Ageto microgrid controllers into Generac’s BESS solutions and generators.

Acquisition of PowerPlay Battery Energy Storage Systems

On June 27, 2024, Generac Power Systems announced its acquisition of PowerPlay Battery Energy Storage Systems, a division of SunGrid Solutions Inc.

PowerPlay specializes in providing turnkey BESS solutions for C&I projects, with capacities up to 7 MWh. This acquisition supports Generac’s commitment to providing a more comprehensive ecosystem of products and solutions to commercial and industrial (C&I) customers. The PowerPlay business will continue to operate in Cambridge, Canada, serving as a dedicated research and development facility for Generac’s Commercial and Industrial Battery Energy Storage System (C&I BESS) solutions.

10. Vattenfall

Vattenfall is one of Europe’s largest providers of fossil-free electricity and is actively transforming its production portfolio to achieve “fossil freedom”. It is exploring new opportunities in solar energy technology and battery storage, with a focus on integrating solar energy with wind farms.

Battery Storage Systems

Vattenfall’s energy storage efforts primarily focus on Battery Storage Systems integrated with renewable generation.

The company operates large battery storage systems, often combined with wind and solar parks to create hybrid parks that enhance grid stability by balancing intermittent generation. The Haringvliet Energy Park in the Netherlands is a prime example, combining battery, wind, and solar technologies.

Vanttenfall also has a 22 MW battery operational at Pen y Cymoedd, one of Europe’s largest onshore wind farms. It has connected 88 BMW batteries at the Princess Alexia wind farm in the Netherlands to form a mega battery for storing wind energy.

Ray Wind Farm Battery@Ray: The company has deployed a 20MW, 2-hour battery energy storage system (BESS), known as Battery@Ray, adjacent to its 16-turbine Ray Wind Farm in northeast England. The wind farm, in operation for over six years, supplies about 10% of Northumberland’s energy needs.

According to Vattenfall, a single charge from the farm could power 3,500 UK households for 24 hours. Co-locating the battery with the wind farm enables shared infrastructure, such as site roads and grid connections, thereby improving overall cost efficiency.

Mobile Battery Systems

Vattenfall also deploys mobile battery storage systems, for instance, used at the 2019 World Ski Championships to provide carbon-free power for snowmobiles and electric vehicles.

The Zeevonk project

The Zeevonk project is a groundbreaking renewable energy initiative in the Netherlands, developed through a joint venture between Vattenfall and Copenhagen Infrastructure Partners (CIP). Located approximately 62 kilometers off the Dutch coast, the project encompasses a 2 GW offshore wind farm and a 50 MW floating offshore solar farm. A significant portion of the energy generated will be converted into green hydrogen at a 1 GW electrolyser facility located at the Port of Rotterdam.

In December 2024, Google entered into a 15-year power purchase agreement to procure 250 MW of wind power from the Zeevonk project, supporting its operations in the Netherlands and advancing its goal of operating on 24/7 carbon-free energy by 2030.

The project has progressed to the front-end engineering design (FEED) phase, with the UK-based engineering firm Wood awarded the contract to provide detailed cost estimates and design plans for the hydrogen facility over ten months. Additionally, site investigations commenced in December 2024, involving comprehensive seabed surveys across the designated area. Zeevonk is scheduled to be operational by 2029.

Vattenfall plans to invest a total of SEK 170 billion between 2025 and 2029, with the majority (61%) focused on new fossil-free electricity generation projects, including Zeevonk.

Recent Collaborations, Acquisitions, and Investments

Final Investment Decision to Build Nordlicht 1 and 2 offshore wind farms

Vattenfall has made a final investment decision to build the Nordlicht 1 and 2 offshore wind farms, with construction set to begin in 2026 and operations expected by 2028. Located 85 km north of Borkum in the German North Sea, the Nordlicht cluster will have a combined capacity of over 1.6 GW and produce around 6 TWh of electricity annually.

Nordlicht 1 will become Germany’s largest offshore wind farm at approximately 980 MW, while Nordlicht 2 will add around 630 MW. The project comprises 112 Vestas V236-15.0 MW turbines and will utilize low-emission steel in the towers to reduce its carbon footprint by 16%.

BASF, which previously acquired shares in the project, will continue its collaboration by securing a long-term renewable power supply for its chemical operations. Vattenfall will repurchase the shares in the Nordlicht cluster that BASF acquired in 2024. The final investment decision for Nordlicht 2 is conditional upon permit approval.

Vattenfall signs agreement to optimise battery park in the Netherlands

Vattenfall has partnered with international energy storage company Return to operate and optimise a 50 MW battery park in Waddinxveen, southern Netherlands, starting in the first half of 2026. Under the eight-year agreement, the battery, which offers 100 MWh of storage, will connect to Tennet’s high-voltage grid. This large-scale system will enhance flexibility and grid stability, playing a key role in Vattenfall’s push toward a fossil-free future. As part of its broader strategy, Vattenfall aims to bring up to 1.5 GW of external battery capacity to market in Northwest Europe, leveraging its extensive experience in energy storage and optimisation across the region.

In its interim report for Q1 2025, the company mentioned these new initiatives as well:

- Vattenfall and Svenska Kraftnät launched a pilot concept to enable faster electricity grid connections

- New power purchase agreement signed with chemicals group LyondellBasell for 450 GWh of electricity annually from the Nordlicht 1 offshore wind farm

- Vattenfall secured permits for the Kattegat Syd offshore wind farm in Sweden and the Ourack onshore wind farm in the UK.

What’s Next

The energy storage industry is evolving rapidly, driven by major leaps in technology, increased regulatory support, and enhanced grid integration. From long-duration storage systems and battery chemistries to hybrid solutions and virtual power plants, the way energy is stored and delivered is being reimagined.

This transformation opens up new opportunities for energy companies, utilities, and innovators to lead in resilience, sustainability, and energy efficiency.

However, staying ahead requires more than awareness. It demands insight into emerging technologies, strategic partnerships, and the activities of competitors.

That’s where GreyB can support you. Our experts can help you track:

- What’s new in long-duration, short-duration, and grid-scale storage technologies?

- Which companies or startups are building the future of energy storage?

- Where are the R&D and patenting hotspots—and what are your competitors focusing on?

Fill out the form and connect with our team to explore the right opportunities in energy storage, backed by data and deep research.

How Can We Help You?

We support industry-leading R&D and Innovation professionals through complex problems. Describe your challenge, and let us bring clarity and expertise.