Challenge: Residue Build-Up in Airless Pump Bottles

A leading food and beverage brand faced a persistent issue with its airless pump bottles: product residue remained in the nozzle and pump mechanism, resulting in wastage and frustrating consumers who couldn’t entirely dispense the product.

For a company focused on sustainability, efficiency, and consumer satisfaction, this problem was significant. The challenge was to find a packaging design that worked with condiment-like viscosities, eliminated residue, and could be scaled cost-effectively without disrupting existing systems.

Research Strategy: Looking for Solutions Outside the Food Industry

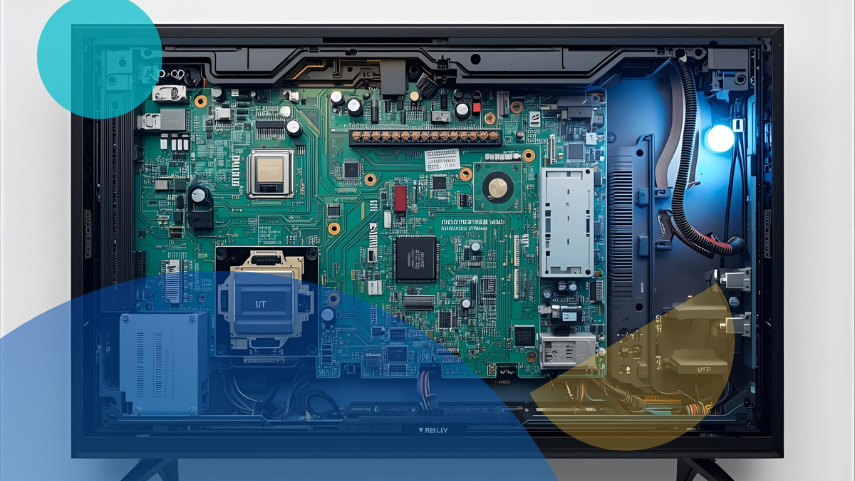

Instead of limiting the search to packaging innovations within the food industry, the team explored outside signals.

Electronics rely on precision dosing systems to dispense adhesives with remarkable accuracy and minimal waste. This idea inspired a new approach to dispensing food and beverage products more efficiently.

Outcome: Smart Dosing Cap

Kisling’s smart dosing cap (called the ergo cap or “SmartPen”) is a patented dispensing cap that gives the operator fine control of adhesive flow. It features a self-cleaning flow path mechanism to prevent clogging or sticking.

Precision dispensing + reduced waste

Because the cap provides fine control, self-cleaning, and allows use until the last drop, the system minimizes material waste and overspray or dripping. That is hugely appealing if you port this into other liquid packaging domains (cosmetics, food additives, reagents, etc.).

User ergonomics and reliability

The single-handed operation and anti-clogging design make it practical in real work settings. Many high-precision dispensers fail in usability. This cap bridges precision with usability. For cross-industry packaging, that kind of balance is often the missing ingredient.

Research Process: How Did GreyB Help?

Defining the Research Scope

The engagement began with a well-defined problem statement and a clear understanding of the client’s existing expertise within their own packaging domain. The client sought GreyB’s support to explore how other industries approach similar challenges, particularly in safety, usability, sustainability, and compliance.

Building on this objective, the research team outlined key research parameters aligned with consumer expectations and regulatory requirements. The focus was to look beyond the conventional packaging industry and identify transferable innovations from sectors such as pharmaceuticals, medical, and cosmetics, where similar technical or regulatory challenges have been successfully addressed.

Conducting Cross-Industry Research

The next step involved deep cross-industry exploration to capture diverse insights and technologies. GreyB’s research team analyzed patents to uncover new designs and materials, reviewed industry reports to understand technological and market trends, and studied competitors to learn how similar challenges were addressed across sectors.

Additionally, consumer feedback and market data were examined to validate solution viability. This comprehensive approach ensured that the collected ideas were driven by the problem’s essence, rather than being confined to a single industry’s perspective.

Evaluating Feasibility and Applicability

Once potential solutions were identified, GreyB evaluated each one through a structured feasibility analysis. Key factors included:

- Material properties: sustainability and compliance with regulatory requirements.

- Manufacturing compatibility: adaptability to existing production systems.

- Cost-effectiveness: potential for efficient, large-scale implementation.

- Regulatory alignment: adherence to safety and packaging standards.

This rigorous evaluation ensured that the final recommendations were both innovative and practical for real-world adoption.

Identifying Key Partners and Suppliers

In the final stage, the team identified the right partners and suppliers to help bring these solutions to life. They conducted targeted supplier research to locate vendors with expertise in the relevant technologies, followed by direct outreach for validation, customization, and feasibility discussions.

By facilitating collaborations and ensuring seamless integration, GreyB helped clients adopt cutting-edge, cost-effective packaging solutions ready for implementation.

Schedule a Consultation With Our Experts Today

Get in touch by filling out the form below