The galvannealed coatings possess two most important qualities: Corrosion protection and High Surface quality, which makes them irreplaceable in numerous automotive applications, construction machines, buildings, and civil engineering structures.

Conventionally, steel sheets hot dipped in zinc (galvanized) were heavily used. However, with time the focus of these industries is shifting towards the usage of hot dipped steel sheets subjected to annealing treatment as well.

Consider the instance of countries that remain covered with snow for large parts of the year. De-icing salt and sand are spread on roadways to clear the way for automobiles. However, this, in turn, increases the corrosive environment for automobiles. Continuing on the same example for countries indulging in such practices, for galvannealed steel sheets to be successfully used in outdoor applications, improvements in certain critical areas are needed.

The majority of the researchers whether associated with big corporations, universities/ institutes or even individual researchers while reading till this stage would agree – “Corrosion has been the strongest enemy of steel in outdoor utilities”.

We are also on the same page with you, BUT knowing only this is NOT sufficient. It becomes imperative for the researchers to know what exactly the problem in these coatings is, and the latest solutions that can be adopted.

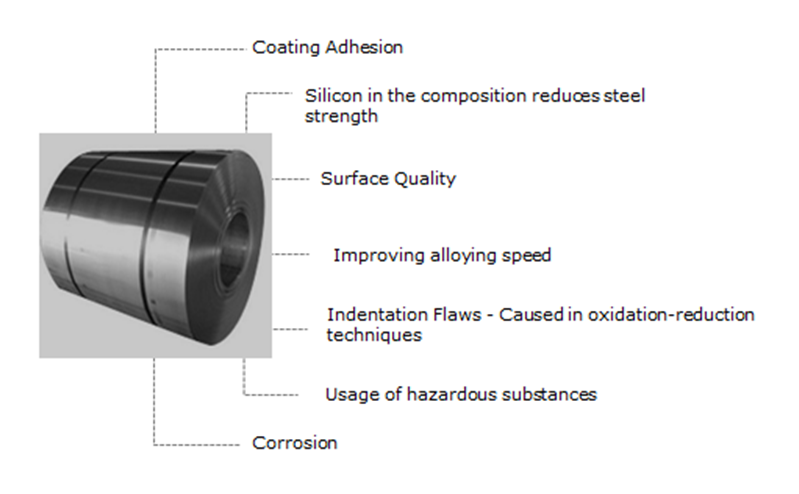

Coming back to the issues in Galvannealed coatings which are gaining high attention in the recent time frame, we performed an analysis to identify these issues.

The major problem regions that came up were:

But as mentioned, knowing what the problem is not sufficient. We delved deeper into some of these problems to understand the solutions that are being developed.

But as mentioned, knowing what the problem is not sufficient. We delved deeper into some of these problems to understand the solutions that are being developed.

Surface Quality of Galvannealed Steel

The surface quality of a galvanized steel sheet generally degrades due to non-uniformity in coating and a coating defect resulting from Fe—Si oxides or only Si oxides precipitated at the surface of base iron.

To overcome this problem, some of the solutions which have been suggested in the recently published technical literature include:

Adding Copper and Nickel in the Steel.

Intensively performing descaling in roughing rolling and finish rolling.

The appearance of the coating of steel sheets containing chromium can be improved by removing chromium oxide; by converting it into chromic acid dissolved in an alkaline aqueous solution.

The Coating Adhesion Problem

When a coated steel sheet is used in outdoor applications that involve a lot of bending/pressing, the plated layer often peels off the surface.

Even if the plated layer does not peel off, loosening of adhesiveness between the plated layer and the base steel sheet produces voids in an area where the adhesiveness is lost, causing outside air and moisture to enter the voids, and thus eventually leading to corrosion.

Nippon Steel and Sumitomo Metal Corporation are one of the companies which have been working on to resolve this problem.

Some of the breakthrough solutions which have been shared to improve the coating adhesion include:

Flattening the concentration gradient of Fe in the plated layer.

Intra-galvannealed-layer diffusion treatment step, maintaining the sheet at 250 to 450 degree Celsius.

Pre-alloying heat treatment preferably at a temperature range of 850°F to 950°F, for 1 to 10 hours in a protective environment should be carried out. This treatment increases % of Fe in the coating, thus reducing the gaps in grain structure. This ultimately leads to preventing liquid metal embrittlement.

From the above two examples, you might have got an idea that researchers can save their time by getting such a problem-solution analysis. Though in the above examples we have restricted the details for the brevity of article, but when it comes to usability of such analysis, I bet you would not disagree that such details can add value. This type of analysis is very popular among R&D heads to quickly see opportunities in technologies where they are operating and to get the solution to problems that they are trying to solve.

Though in the above examples we have restricted the details for the brevity of the article, when it comes to usability of such analysis, I bet you would not disagree that such details can add value. This type of analysis is very popular among R&D leader to quickly see opportunities in technologies where they are operating and to get the solution to problems that they are trying to solve.

If you are working on such problems, write to us and we can share a detailed version of the problem-solution analysis.

Authored by: Deepika Kaushal, Manager, Patent Landscape.

Recommended Read: If Smart switches intrigue you and you ever wondered where innovation could be done in the Smart Switches domain, we recently conducted a whitespace analysis to find answers to the next billion-dollar industry. You can read the article here- Smart Switches- A WhiteSpace Analysis