The HVAC industry faces challenges in energy efficiency, rising operational costs, and sustainability. According to the US Department of Energy, HVAC systems account for nearly 40% of energy consumption in commercial and residential buildings. Air conditioners alone account for about 12% of the electricity used in US households. Annually, this amounts to approximately $29 billion in operational costs.

Traditional systems struggle to keep pace with changing environmental conditions, resulting in frequent breakdowns and suboptimal performance. In addition, improper maintenance is a leading cause of HVAC system failures, accounting for approximately 40% to 60% of breakdowns. These issues are driving industry leaders to seek predictive systems to reduce downtime and costs while extending equipment life.

Emerging HVAC innovation trends address these challenges by integrating machine learning, real-time sensors, and innovative materials. Some AI-driven HVAC systems have already demonstrated energy savings of up to 15.8%, equating to annual savings of $42,000. These systems can also predict necessary maintenance and even clean themselves automatically!

GreyB examined 100 of the latest HVAC-related patent innovations by leading companies and well-known universities to identify the key trends shaping the HVAC industry. The analysis revealed four primary trends: Energy Efficiency and Optimization, System Reliability and Maintenance, Environmental Control, and Material Durability.

This study highlights these key innovation trends and their impact on the HVAC sector.

Download the full report in PDF format to explore comprehensive insights on these HVAC innovation trends at your convenience; this report is an essential resource for your R&D team.

Fill out the form below to get a PDF copy of this report directly in your inbox.

Innovation Trends in AI-Powered Sensors: Improving HVAC Efficiency by Reducing Energy Waste

Energy efficiency remains a focus area for the HVAC industry, driven by the need to reduce operational costs and environmental impact. Innovations in this area, such as utilizing machine learning for dynamic control, can reduce energy consumption by 20% and enhance system performance.

This ML Model Cuts Through HVAC Noise to Predict Cooling Accurately

Inaccuracies in temperature, humidity, airflow, and other similar data collected result in inaccurate predictions of the cooling capacity. This data can be inconsistent and affected by noise (unwanted signals), leading to poorer overall performance.

Researchers at Guangdong University have developed a system that surpasses traditional systems by utilizing advanced signal processing and a machine learning model. This system effectively filters out noise without losing information critical for analysis.

The processed data is analyzed using a neural network, with a focus on the most critical data points. This method provides faster and more accurate predictions for cooling capacity. It helps lower energy use and improve system efficiency compared to traditional methods.

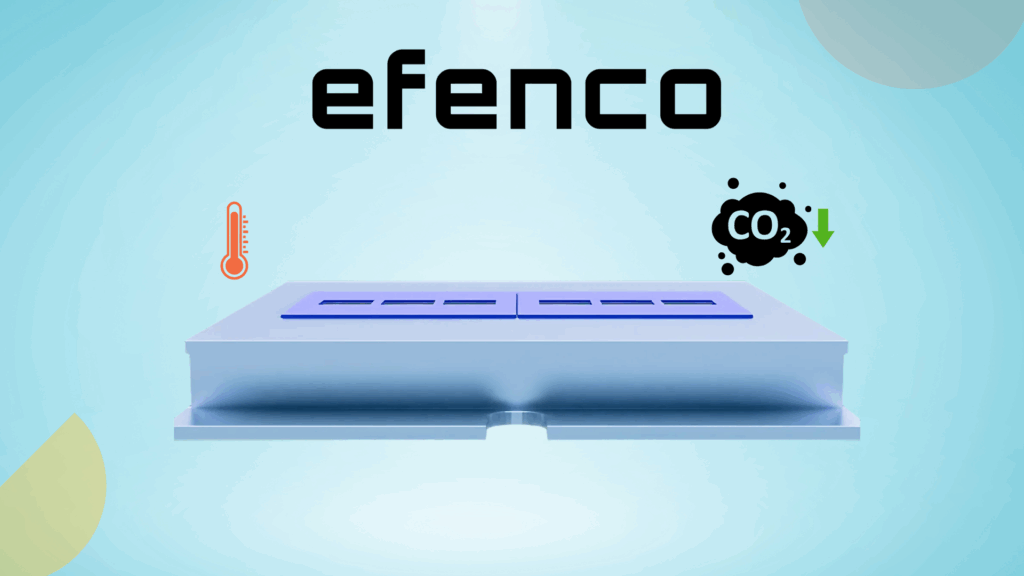

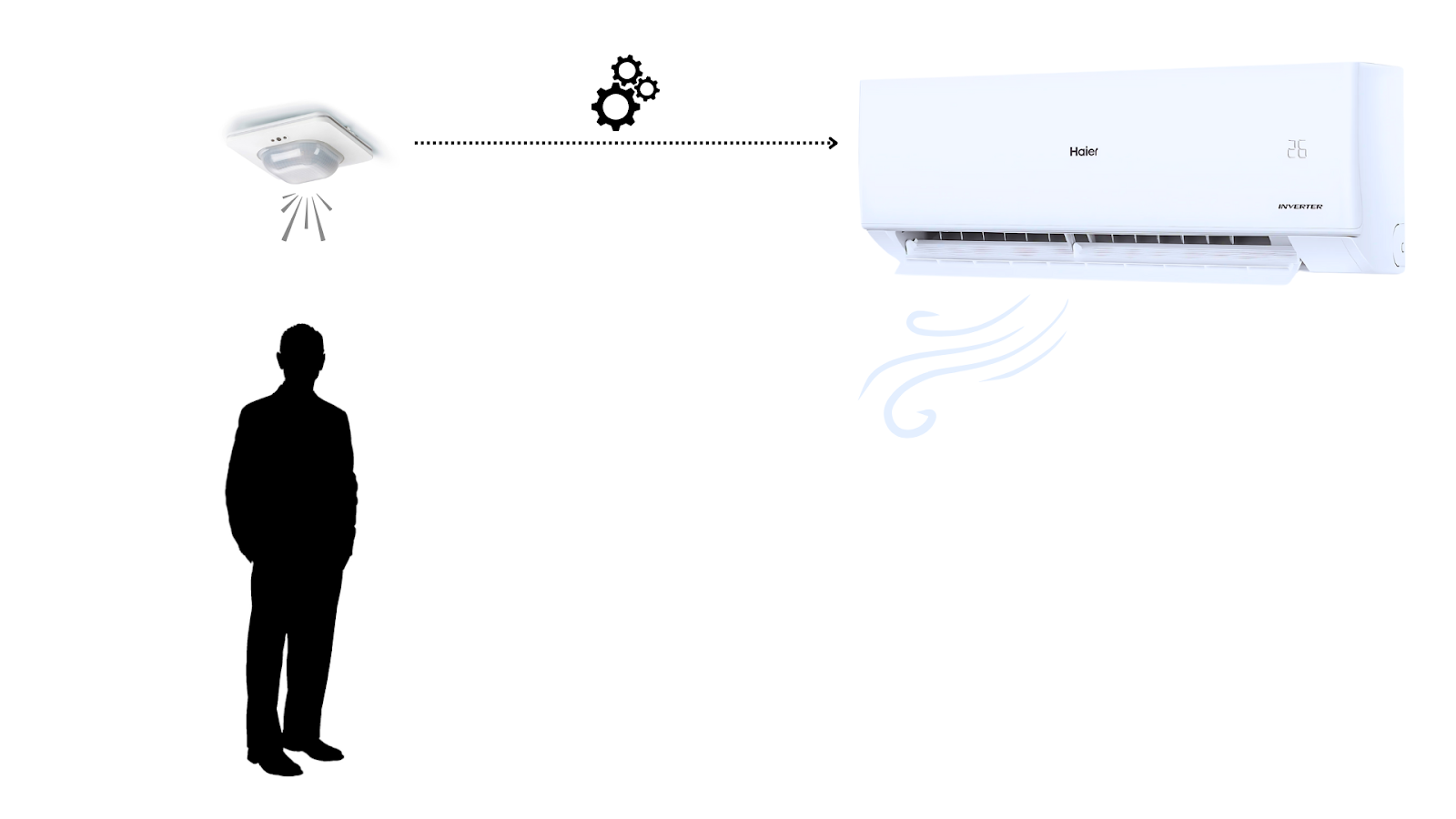

Smart Sensors that Switch ACs On/Off by Knowing When You’re in the Room

Conventional air conditioning systems aim to enhance energy efficiency by detecting the presence of occupants in the room. However, these systems often produce false readings, detecting occupancy when the area is vacant. This leads to energy waste, such as identifying a vacancy when the room is occupied, which causes discomfort to occupants.

Haier has addressed this issue by utilizing scheduled occupancy and real-time triggers. The system accurately detects room occupancy using motion sensors, door sensors, and keycard access systems. It also utilizes a specific controller that dynamically switches between normal and energy-saving modes according to a predetermined schedule. For instance, if the room is expected to be occupied during certain hours, such as during sleep time, it automatically switches to energy-saving mode and remains on.

When a room is detected as unoccupied during specified time frames, the system operates in energy-saving mode, adjusting the temperature or reducing fan operation. Upon detecting motion or door activity, the system transitions to the normal mode to restore occupant comfort. This innovation enables efficient energy use while ensuring user comfort through adaptive, precise control mechanisms.

GreyB’s analysts found these inventions using Slate, a technology scouting tool that finds and categorizes patent-backed inventions into a neat dashboard. Simply ask, “What are the latest HVAC innovation trends?”.

Using a simple, one-line query, Slate will provide the most relevant results in an interactive dashboard within minutes!

This will significantly reduce your research time and help you find inventions related to your field of interest. Try it out using the form below.

Using Real-Time Data to Reduce HVAC Energy Consumption using the USAC Framework

Existing HVAC systems are not energy-efficient because they rely heavily on their default settings. These systems often fail to adapt effectively to changing environmental conditions, including variations in temperature and humidity. Additionally, HVAC systems don’t always correctly coordinate primary components (chillers, cooling towers) and secondary components (air handling units, ducts). This results in increased energy waste while straining equipment and causing occupant discomfort.

A case study of Jupiter Hospital in Pune, India, demonstrated that operational improvements in HVAC systems, achieved by optimizing control settings, resulted in a 10% reduction in energy consumption. This shows the potential for efficiency improvements in older systems via retrofitting.

Bert Labs has created an energy management system for HVAC that addresses this issue. It uses real-time sensor data and utility functions to manage prediction uncertainties using a machine learning model. It uses the Utility Soft Actor-Critic (USAC) Framework to achieve this. The USAC Framework enables AI to learn more effectively by determining when to take risks and when to play it safe, based on its level of uncertainty about its decisions. It balances exploring and sticking to known solutions to make smarter choices faster. Think of it like teaching an AI to be cautious and adventurous at the correct times!

This system offers an adaptive solution for optimizing HVAC operations. It improves energy efficiency by up to 20% while reducing operational risks in changing environments.

Machine Learning Keeps HVAC in Sync with Real-Time Conditions

Due to their rigid control algorithms, conventional HVAC systems often struggle to maintain thermal comfort as outdoor temperatures and user preferences change. Their slow response times lead to inefficient energy use and compromised comfort.

Bert Labs offers a solution that leverages sensors to monitor external conditions and user inputs for temperature and airflow. The system can dynamically adjust airflow, temperature, and other settings by algorithmically processing this data. This approach optimizes thermal comfort through real-time adjustments, creating a more responsive and user-centered climate control experience.

The company has extensive experience in developing commercial-grade machine learning and AI systems, such as Bert Optimus and Bert Geminus, which predict the performance of factories in real-time. They have also implemented their digital twin technology in HVAC systems. Hence, related innovation patents are coming up. Bert Labs can easily leverage its connections in commercial and retail building projects to optimize HVAC systems using these technologies.

Similarly, Copeland has also created a system for optimizing HVAC performance using machine learning. This system dynamically adapts to real-time data and external inputs, such as weather forecasts or energy price fluctuations, ensuring occupant comfort and efficiency.

New Heat Pump Design Stays Efficient Even in Extreme Temps

Conventional heat pumps struggle at high temperatures, as this decreases their efficiency (Coefficient of Performance, or COP) and reduces heating capacity. These traditional systems lack effective methods to mitigate this issue through adaptive refrigerant control, resulting in energy inefficiency and performance degradation. The US Department of Energy found that adaptive supervisory control algorithms can reduce HVAC energy consumption by over 15% compared to traditional baseline systems.

Panasonic has designed a heat pump system that solves this efficiency challenge. The system features a primary and a backup refrigerant circuit, utilizing sensors to adjust refrigerant pressure and temperature automatically. This method enables the system to maintain a high coefficient of performance (COP) even as the heating water temperature increases, thereby enhancing energy efficiency and performance.

This system is adaptable for HVAC applications, such as water heating or room heating.

Technological & Regulatory Roadblocks to foresee for these HVAC innovation trends:

- Integration Challenges: The systems rely on advanced technologies, including machine learning and AI. Integrating them seamlessly into existing HVAC infrastructure could face compatibility issues with older hardware or software systems.

- Data Privacy and Security: These systems collect extensive real-time data about building conditions and user behavior, and they must comply with data protection laws like the GDPR (General Data Protection Regulation) in the EU or the CCPA (California Consumer Privacy Act) in the US. Failure to ensure secure data management could result in significant legal and financial penalties.

- Energy Efficiency Regulations: HVAC systems are subject to stringent energy performance standards in regions such as the EU’s Energy Efficiency Directive and ASHRAE Standards (e.g., ASHRAE 90.1) in the US. Ensuring the new systems meet these regulations could be challenging if they do not sufficiently improve energy efficiency.

- Safety and Performance Standards: HVAC systems must comply with national and international safety standards, such as ISO 9001 (quality management) and ISO 14001 (environmental management), which can require extensive certification processes.

- Environmental Impact Assessments: Given that these systems aim to improve energy efficiency, they may be subject to environmental impact assessments or regulations regarding refrigerant usage, as outlined in protocols such as the Montreal Protocol, which governs the use of refrigerants to prevent substances that harm the ozone layer.

Innovation Trends in Materials: Making HVAC Systems Last Longer and Save on Maintenance Costs

Improving the durability and longevity of HVAC system components, such as compressors and blower motors, reduces maintenance costs and extends the equipment’s lifespan. Recent innovations in this area emphasize automating maintenance processes, addressing material corrosion, preventing system failures, and minimizing downtime.

Using Sacrificial Anodes to Prevent HVAC Failures by Detecting Corrosion Early

Current corrosion evaluation methods are unable to effectively assess the state of damage in tight-space areas. This inability leads to unexpected failures and reduced durability of heat exchangers.

Mitsubishi Electric has developed a corrosion evaluation system that utilizes a multi-layered sacrificial anode structure with small holes exposed to the environment. This component simulates the conditions of the heat exchanger’s finned areas, allowing for precise corrosion monitoring in these critical zones. Integrating such components in heat exchangers is easy. It enables timely maintenance and enhances system reliability.

Self-Cleaning AC Filters Cut Maintenance and Improve Air Quality

Air conditioner filter systems often struggle with the accumulation of dust and debris over time. According to Martin Air HVAC, even a small layer of dust and debris, less than an eighth of an inch, can impact the performance of your coils and components. This results in reduced air quality, decreased system efficiency, and increased maintenance requirements. Existing cleaning mechanisms deform the filters during operation, causing them to become misaligned or stuck.

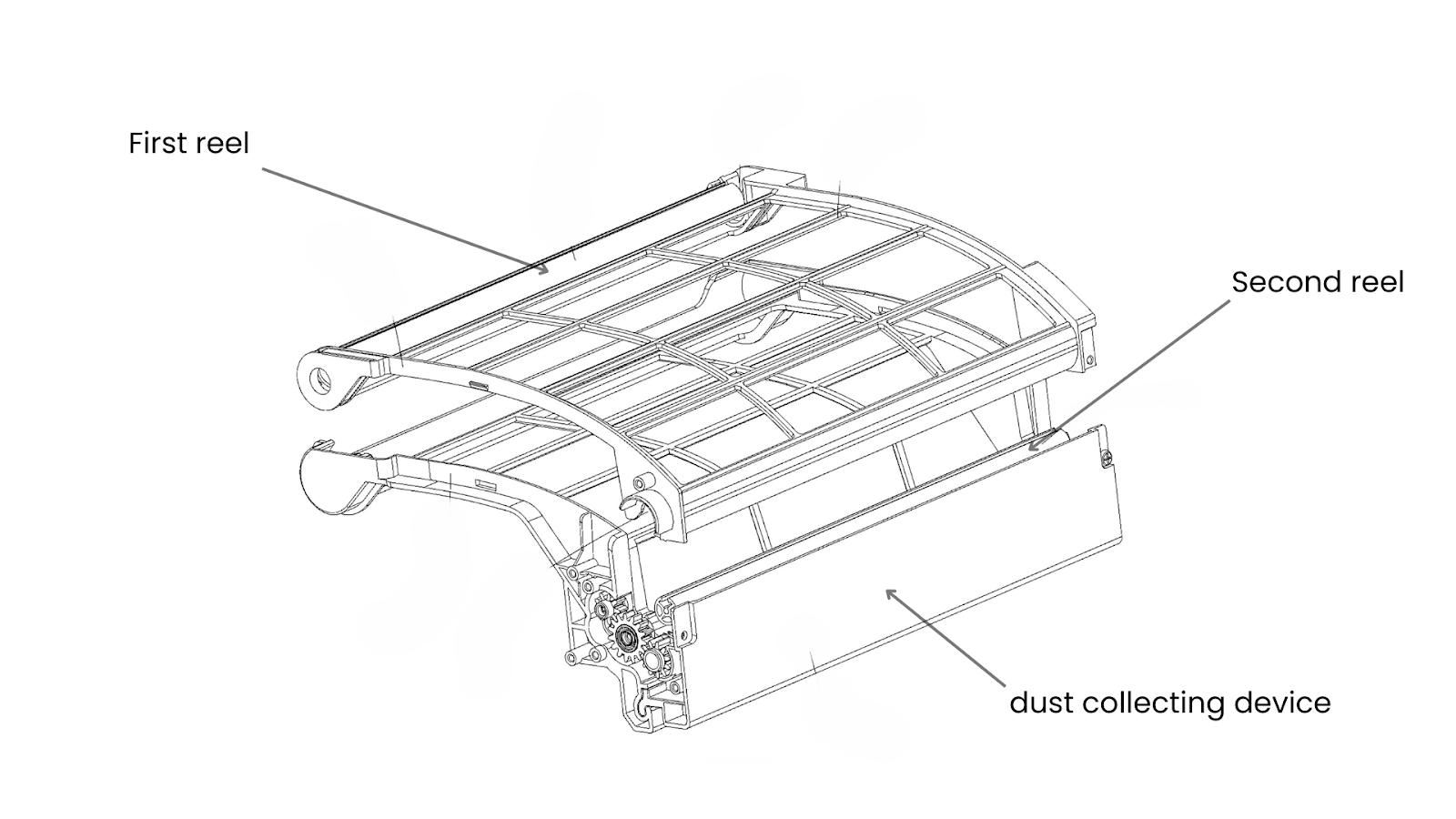

Haier has designed a system that addresses the issue of inconsistent cleaning in air conditioners. This system has a self-cleaning structure that uses two mechanical reels to move the filters. This enables smooth, controlled filter movement during cleaning, preventing deformation or misalignment.

It also has a dust collection device with a brush that removes accumulated dirt and debris as the filter moves. The collected waste in the dust box is easily disposed of.

Temperature Sensors Keep ACs Running Smoothly by Preventing Freezes.

HVAC evaporator coils often face performance issues due to frost buildup. Low refrigerant pressure, dirty coils, or insufficient airflow are typically the causes of this issue. Operating under low refrigerant conditions requires the compressor to work harder, resulting in increased energy consumption and potential damage to the compressor over time. Dust accumulation increases the pressure drop across the coil, resulting in a 7% reduction in airflow and a 5% decrease in performance.

Conventional solutions use freeze stats to deactivate the compressor when freezing is detected. But these methods are localized and inefficient. They often fail to detect freezing across the evaporator, leading to prolonged downtime, user discomfort, and increased maintenance costs.

Lennox has developed a system to prevent freezes by utilizing temperature sensors to counter this issue. In the system, a temperature sensor measures the refrigerant’s saturated suction temperature (SST). If the SST drops below the first threshold, the controller starts a timer and actively monitors the temperature to ensure it remains above the second threshold. If the temperature falls below the second threshold, the system adjusts the compressor’s speed or cycles it on and off. This system effectively mitigates freeze risk, improving system efficiency, protecting the compressor, and minimizing downtime compared to traditional freeze stats.

Ultrasonic Tech Zaps Ice Off HVACR Systems for Peak Performance

Ice accumulation on HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) surfaces, such as evaporators, reduces efficiency, increases energy consumption, and poses a potential mechanical risk. Prolonged ice buildup can reduce system efficiency by up to 30%. Existing defrost methods are often energy-intensive. While specific energy consumption varies, defrost cycles can account for approximately 10–20% of a heat pump’s total energy usage during winter. They’re also relatively slow, taking up to 15 minutes at every 90-minute cycle, and lack precision.

UT–Battelle has developed a system that utilizes an ultrasonic energy source to mitigate ice buildup on HVACR surfaces. The system prevents accumulation by vibrating the ice-prone surfaces at ultrasonic frequencies ranging from 30 kHz to 60 kHz. It also enhances the speed of ice removal, requiring only around 5% of the time compared to typical HVACs. It even verifies the completion of ice removal, ensuring optimized performance and energy efficiency.

Automatic Cleaning Stops AC Drain Clogs and Protects Your Home.

In traditional air conditioning systems, condensate drain tubes often clog due to the accumulation of sludge. This results in water overflow from the air handler, a common issue in the system, which can damage the flooring or furniture. Current systems rely on maintenance to unclog these drain lines, which delays resolution and increases the cost and maintenance stress.

This newly patented air conditioning system is a promising solution to this problem. It automatically detects and resolves clogged condensate drain tubes without human intervention. It uses two condensate sensors at different heights to monitor water accumulation and clogs in the drain tube.

A primary valve blocks backflow to the air handler, while secondary valves introduce cleaning agents, like compressed air, into the drain tube. A microcontroller operates these valves based on sensor inputs, initiating cleaning cycles that alternate bursts of compressed air and cleaning solution to break and flush out clogs.

Machine Learning Classifies HVAC Systems to Reduce Maintenance Hassles

HVAC systems (e.g., heat pumps, air conditioners, variable-speed systems) have unique components, operational parameters, and service requirements. Conventional methods for identifying HVAC system types rely on manual processes, such as serial number lookups or records from homeowners. These methods are prone to human error, data loss, or damage.

Research indicates that over 50% of residential air conditioning systems in the United States are improperly installed. This results in frequent start-and-stop cycles, equipment freezing, loose wiring connections, and higher repair costs.

A recent invention by SmartAC introduces a machine-learning-based system for automatically classifying HVAC system types. The system uses sensors to measure supply (e.g., temperature and pressure) and return airflow data. A machine learning model processes these inputs and predicts the type of HVAC system that is required. This system eliminates reliance on typical identification methods, enhances accuracy, and reduces manual intervention.

These innovations contribute to lower lifecycle costs and increased customer satisfaction. As consumers demand more reliable and hassle-free HVAC solutions, system reliability and maintenance automation advancements will be increasingly valued.

Technological & Regulatory Roadblocks to foresee for these HVAC innovation trends:

- Integration Complexity: Systems that combine multiple cleaning or deicing mechanisms (e.g., ultrasonic and temperature sensors) may face challenges in integration, particularly with existing HVAC infrastructure.

- Reliability of Self-Cleaning Systems: While self-cleaning filter systems improve maintenance, they may struggle with consistency, particularly if mechanical parts wear down or clog. The design’s longevity in real-world conditions (e.g., in commercial or high-use settings) might lead to unexpected failures.

- Sensor Sensitivity: Systems relying on ultrasonic vibration for ice removal or temperature-based freeze mitigation depend heavily on precise sensors. Any inaccuracies could lead to inefficient operation or damage to the HVAC components.

- Environmental Regulations: Certain technologies, such as refrigerant management systems or self-cleaning mechanisms, may require adherence to strict regulations governing the use of refrigerants and hazardous substances. For example, in the U.S., the Environmental Protection Agency (EPA) regulates refrigerant use under the Clean Air Act. Any shift in refrigerants or the introduction of new cleaning agents must align with these policies.

- Energy Efficiency Standards: Products like HVAC systems with new deicing technologies or self-cleaning filters may not immediately meet updated energy efficiency standards such as those set by the U.S. Department of Energy (DOE). Systems that incorporate machine learning or ultrasonic tech must pass rigorous testing for energy savings and operational effectiveness to qualify for various green building certifications (e.g., LEED).

- Building Code Compliance: Self-cleaning systems or innovative HVAC components may need to meet various building codes for installation. In the European Union, CE marking regulations require compliance with safety, health, and environmental protection standards. Additionally, in the U.S., compliance with National Fire Protection Association (NFPA) standards might be required to ensure safe operation in various building types.

HVAC Design Innovation Trends: Newer Designs and Sorbents for Greater Control Over Indoor Air Quality

Controlling humidity and air quality for indoor comfort and health remains a key trend. Innovations focus on developing adaptable HVAC systems that precisely manage these environmental factors to ensure optimal indoor conditions. Let’s look at some recent innovations that are being worked on.

Metal Sorbents Enhance Humidity Control, Making HVAC Systems Smarter and Greener

Current water capture and humidity control technologies struggle with poor stability, low water uptake capacity, and inefficiency in specific humidity ranges. Existing solutions often rely on costly or difficult-to-scale materials, such as silica gel and zeolites. These materials require energy-intensive regeneration processes for large-scale deployment, making them unsuitable for widespread adoption.

MIT has solved this using advanced metal-organic absorbing materials for adjustable water capture and release. These sorbents exhibit high water uptake capacity and good stability. They only lose about 5.7% of their working capacity after more than 450 cycles of adsorption and desorption. Metal sorbents can be manufactured from readily available and inexpensive materials, such as zinc and nickel. These cost 20–30% less than conventional options.

These materials can be utilized in energy-efficient air conditioning, providing scalable, cost-effective solutions with superior performance to traditional materials.

Smart HVAC Monitors Humidity to Mitigate Viral Risks Indoors

Indoor air safety solutions often fail to effectively mitigate the risks of viral transmission in enclosed spaces. An optimal absolute humidity (AH) level greater than 0.010 kg water/kg air is required to reduce the survival and spread of airborne pathogens. Existing HVAC systems struggle to maintain this.

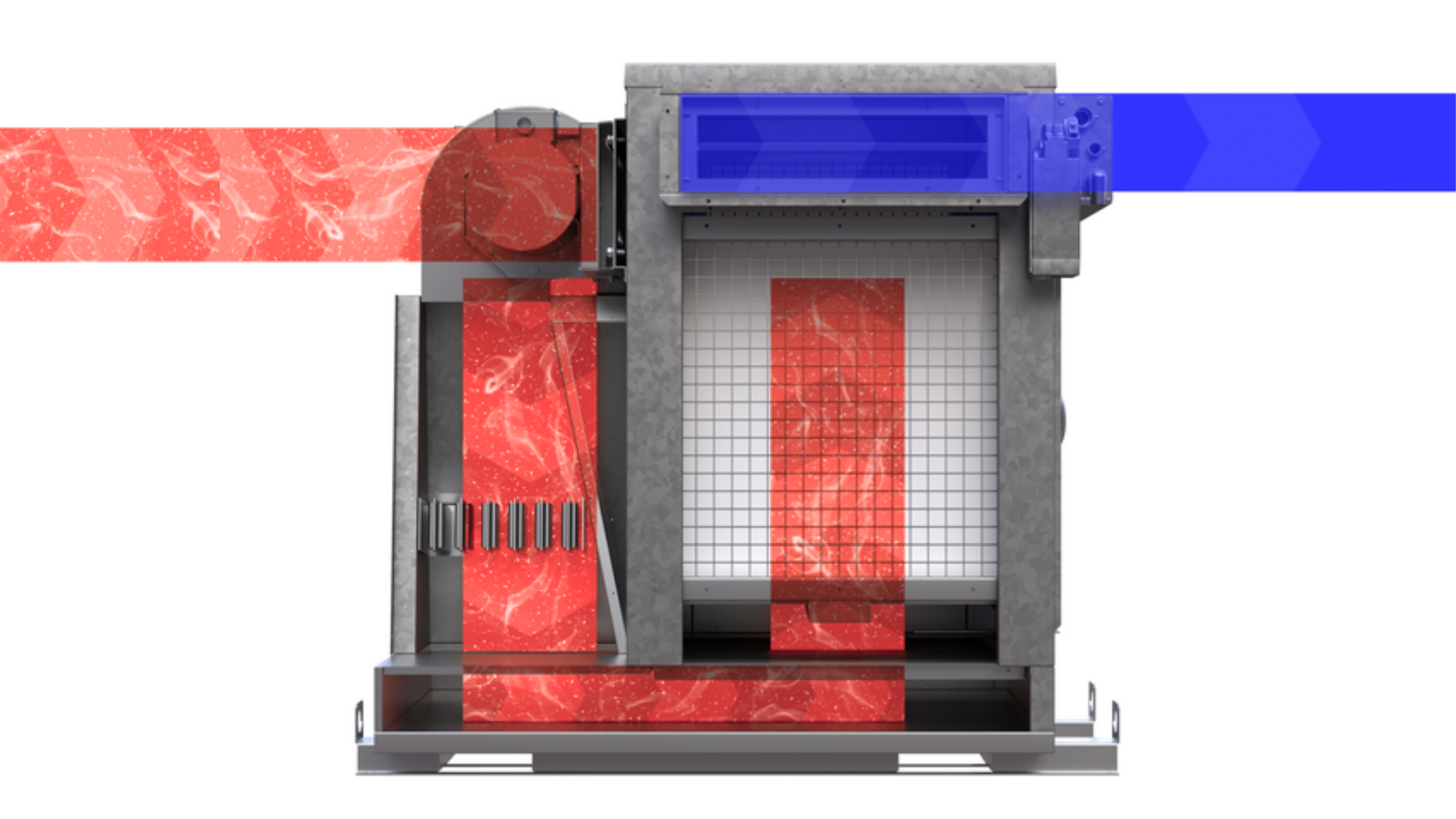

A recently published invention by Channel Content Company uses AH sensors to monitor absolute humidity in enclosed spaces. These sensors transmit AH values to a central processor, which compares them to predetermined safety thresholds. If unsafe levels are detected, the system initiates corrective actions, such as enabling humidifiers or providing safety alerts. This approach ensures real-time viral safety assessment and an automated response mechanism to create a safer indoor environment.

New AC Design Ensures Even Airflow, Cuts Energy Costs

Air conditioning systems often struggle with uneven temperature distribution and air velocity. Studies show that uneven air distribution can create discrepancies of up to 2.77°C between the actual and set AC temperatures. These issues result in reduced energy efficiency, inconsistent air quality, and over-reliance on external air intake. It can also strain the equipment and decrease its lifespan.

A recent invention by Cheong Nam showcases an AC system design that prevents thermal separation, ensuring uniform temperature and airflow distribution throughout the system. This system mixes and purifies indoor and outdoor air while maintaining optimal pressure. This dynamically adjusts the external air intake without increasing static pressure, thereby enhancing air quality and improving environmental adaptability.

Technological & Regulatory Roadblocks to foresee for these HVAC innovation trends:

- Material compatibility: The use of advanced materials, such as metal-organic frameworks or specialized sorbents, may encounter limitations in scalability or compatibility with existing manufacturing processes.

- Operational efficiency: Achieving real-world energy savings and ensuring that the patented systems maintain performance in diverse, non-laboratory environments may be challenging. Variations in humidity, temperature, and external environmental factors can impact performance.

- Integration with existing systems: New materials and methodologies may require significant modifications to existing HVAC systems, posing challenges for businesses relying on legacy technology.

- Cost-effectiveness: Advanced sorbent materials, sensors, and machine learning systems may incur high initial costs, which can hinder large-scale implementation and market penetration.

- Long-term stability: Certain materials, particularly those utilized in moisture adsorption, may degrade over time or become less effective after repeated cycles.

- Environmental standards: In the HVAC sector, adhering to energy efficiency standards, such as the Energy Star certification or ASHRAE standards, can be a challenge. New technologies must meet stringent guidelines for environmental impact to gain market acceptance.

- Material regulations: Metal-organic frameworks and other novel materials must comply with laws related to safety and toxicity, particularly when used in consumer-facing products such as air filtration systems.

- Food safety laws: For processes like apple juice production, regulatory concerns over food safety standards, such as those enforced by the FDA in the U.S. or EFSA in the EU, may pose significant challenges. For instance, new ingredients like Boyi tea extract may need to undergo testing to meet the requirements of food ingredient approval processes.

Conclusion

The HVAC industry is transforming from a utility service to an intelligent, responsive ecosystem by integrating machine learning, advanced materials, and adaptive control systems. This report’s analysis shows the industry’s clear focus on enhancing energy efficiency, ensuring system reliability, and improving environmental control.

These innovation trends address current market demands for cost-effective and sustainable solutions for tomorrow’s HVAC that prioritize innovative technologies and user-centric designs. Companies investing in these areas are well-positioned to lead the market by delivering innovative, reliable, and environmentally responsible HVAC systems.

However, the real challenge lies in effectively identifying and implementing these innovations into your existing systems. Industry leaders will have to cut through a lot of market noise to identify actual innovations from companies with proven potential. Slate can help you do just that.

Access real-time, patent-backed innovations directly related to your projects in a single, intuitive dashboard. Reduce the time spent browsing scattered sources, and experience how this tool can help you pinpoint relevant advancements in minutes. Sign up for a free demo today.