With the scarcity of skilled and cost-effective labor, the food industry is turning to automated food production systems to achieve greater precision and yields. This shift is driving the growth of the food robotics market and opening up a world of possibilities for R&D heads to innovate and revolutionize the food industry.

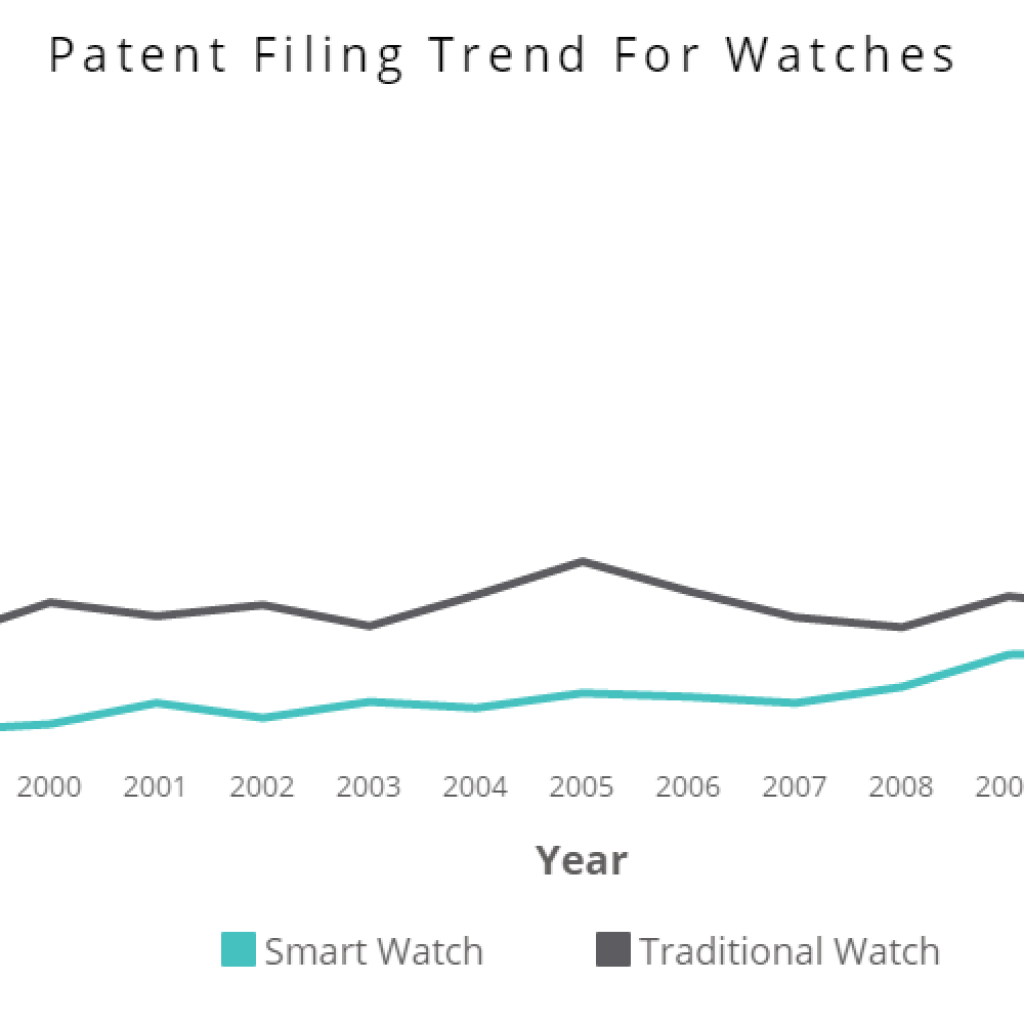

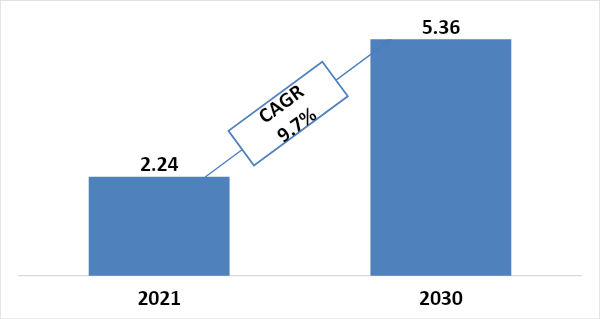

According to a recent report, the global food robotics market was worth $2.24 billion in 2021. Furthermore, experts predict that the industry will reach a staggering $5.36 billion in the upcoming years, with a CAGR of 9.7%. (Source)

Global Food Robotics Market Size during 2021-2030 ($Billion)

But, it isn’t just one but many other factors contributing to the growth of the food robotics domain. With the need for social distancing and hygiene protocols, especially after the COVID-19 pandemic, robots have become the ultimate solution for mundane tasks like packaging, repackaging, and palletizing. As a result, humans can focus on other important aspects of the food production process while the robots take care of the repetitive and tedious tasks. (Source)(Source)

Despite the numerous advantages that food robotics can offer both manufacturers and customers, there are still several challenges that need to be addressed. These include the high installation costs, the complexity of food products, and the ability of robots to recognize different types of food. However, certain food robotics companies and startups are actively working on innovative solutions to tackle these challenges, and we have highlighted the most revolutionizing ones in this article.

Food Robotics is one of the key trends of Food Tech in 2025. Our Food Tech Trends report contains 10 such trends along with key information. Fill out the form to request access:

Major Food Robotics Companies at the Forefront of Innovation

1. Stäubli

Stäubli’s food robotics technology is known for its precision, reliability, and flexibility. The company’s robots are designed to handle various food products, including meat, poultry, fruits, and vegetables. Additionally, their robotic arms can perform precise and delicate operations such as upstream processing, sorting, packaging, and end-of-line palletizing.

Stäubli Robotic Arms

The robots are also equipped with advanced sensors and vision systems that enable them to handle food products accurately, minimizing waste and improving efficiency. Stäubli’s robots meet strict hygiene and sanitation standards, as they are equipped with washdown-ready components and sealed joints to prevent contamination.

Another advantage of Stäubli’s food robotics technology is its flexibility. The robots can be programmed to perform diverse tasks, from handling and processing food products to packaging and palletizing. This allows food manufacturers to optimize production processes and adapt to changing market demands. (Source)(Source)(Source)

2. Rockwell Automation

Rockwell Automation, based in the United States, offers robotics and automation solutions in 6 segments of the food industry, i.e., Dairy, Bakery, Beverage, Brewery, Prepared Foods, and Protein Processing.

It allows manufacturers to quickly adapt to changing consumer preferences by providing real-time, accessible information. Through information-enabled manufacturing, this company helps manufacturers enhance output, boost efficiency, mitigate security threats, optimize resource allocation, and maximize asset utilization. (Source)

It further helps overcome industrial challenges such as Energy Management, Food Packaging, Food Safety, and Operational Excellence. (Source)No wonder food companies like Barry Callebaut and Hillshire Brands have collaborated with Rockwell Automation to utilize their robotic technology. (Source)

3. Universal Robots

Universal Robots, headquartered in Denmark, offers robotics solutions for various industries. Their collaborative robots, or cobots, are widely used in the food and beverage industry for secondary packaging and machine tending processes. They can operate in various environments, from humid greenhouses to refrigerated rooms and hot ovens. They can further do mundane, repetitive tasks that are potentially injurious or in unfavorable conditions for humans.

Cobots can work continuously without breaks, making them ideal for seasonal production bursts and reducing the need for additional temporary workers. The robots are also designed to be versatile as they can be easily redeployed to new product lines or processes as production volumes change.

Additionally, the patented safety system in these cobots enables them to slow down or stop when operators are present. They’re also available in a range of reach and payload requirements, making them suitable for pick/pack/pal applications. They come equipped with built-in palletizing wizards that make customized deployment easy. (Source)(Source)(Source)

A well-made technology always leads to a number of collaborations, and Universal Robots is no exception.

It has partnered up with Phillips Machine Tools India to enhance productivity, and help manufacturers in India recover from the pandemic by providing machine shops with a safe, user-friendly solution to optimize uptime and provide other benefits. (Source)

Another noteworthy collaboration in Universal Robots’ kitty is with Unilever, which has implemented cobots in one of its production plants in Poland. The cobots, specifically six UR10 models, are used for palletizing cartons with the ready-to-sell product packed by employees into boxes. By using cobots for palletizing, Unilever has shortened palletizing time, optimized ergonomics, and relieve employees from strenuous tasks. While also improving the efficiency of its tea packaging process and enhancing the working conditions for its employees. (Source)

We have read about the major companies working in this domain, their direction, and their thought processes in taking Food Robotics to new heights. Now, we shall cover the achievements of start-ups in this sector!

Disruptive Food Robotics Startups Shaping the Future

1. Miso Robotics

Miso Robotics, based in the United States, utilizes artificial intelligence to automate fryer stations through its robotic kitchen assistant. The startup’s robot, Flippy, supports a full menu of fried products through an auto-bin system. Its unique technology enhances food quality by cooking to the chef’s requirements. The best part about Flippy (aside from its name, ofc) is that its installation is quick and easy and can be implemented seamlessly into any restaurant.

In addition to Flippy, this startup has developed a CookRight vision system, transforming traditional grills and fryers into smarter devices. Furthermore, the company is also working on developing an innovative solution called Sippy, the world’s first POS-integrated automatic beverage dispenser and sealer. (Source)(Source)

2. Pudu Robotics

Pudu Robotics, based in China, is a global robotics firm focused on designing, R&D, manufacturing, and selling commercial service robots. Pudu robots can play various roles in diverse scenarios to increase service efficiency and lower costs for caterers. And they are marketed as being exceedingly helpful during high labor costs, difficult recruitment, and severe homogenization. Some of their product names are PuduBot 2, SwiftBot, FlashBot, etc. (Source)(Source)(Source)

In 2022, Quill, Pudu Robotics’ official partner in Jordan, bagged a collaboration with Coca-Cola. Coca-Cola intends to promote and distribute its products using Pudu’s BellaBots at supermarkets and during live events. (Source)

3. YPC Technologies

YPC Technologies, based in Canada, is developing robotic kitchens that can prepare various dishes using fresh ingredients. Its robots can prepare numerous dishes, ranging from simple vegetable soup to complex dishes like risotto with filet mignon on red wine reduction. Its systems use a combination of modern cooking appliances, robotics, computer vision, and artificial intelligence to create unique offerings that are claimed to surpass other robotic kitchen systems in terms of meal variety and quality. By leveraging these technologies, the company aims to transform the food service industry by improving kitchen efficiency, reducing labor costs, and enhancing food quality and safety. (Source)

YPC Technologies Robot

4. Alert Innovation

Alert Innovation, based in the United States, created an e-Grocery technology with its Alphabot® platform. This startup’s automated solution collects and stores food in three temperature zones, facilitating order capacity augmentation by combining bots. It creates many redundant channels for Alphabot, assuring consistent order fulfillment.

This startup’s mobile robots replace traditional warehouse conveyors, lifts, and cranes, boosting the cost-efficiency of floor operations. Furthermore, using Alphabot, the business is developing Novastore, an automated service supermarket. (Source)(Source)(Source)

Sounds cool, right? Well, many other companies think so, too, which can be seen in their collaborations.

In 2016, Walmart began collaborating with Alert Innovation to develop unique technology for its micro-fulfillment centers. Walmart claims the acquisition would allow it to better leverage its shops for storage and fulfill consumer orders more effectively and ultimately acquired Alert Innovation in 2022. (Source)

In 2019, Murata Machinery announced a partnership with Alert Innovation which would allow it to streamline picking operations by incorporating Alphabot® technology into its Muratec systems. (Source)

Future Outlook

The future outlook for food robotics is bright as the industry seeks solutions to address the growing demand for food and beverage products. With the help of robotics, food manufacturers can streamline their production processes, improve product quality, and reduce the need for manual labor.

One key trend that is expected to shape the future of food robotics is artificial intelligence (AI) and machine learning (ML). These technologies will enable robots to become more intelligent and adaptable, allowing them to learn from their environment and optimize their performance over time. AI and ML will also enable robots to perform more complex tasks like quality control and decision-making.

Another trend expected to gain momentum in the coming years is using collaborative robots, or cobots, in the food and beverage industry. These robots will work alongside human workers, enhancing productivity and improving working conditions.

The robotics as a service (RaaS) model is also expected to gain popularity in the food and beverage industry. This model allows companies to access robotics technology on a subscription basis, reducing the need for large capital investments.

Finally, modular and flexible robotics systems will become increasingly important in the food and beverage industry. These systems enable manufacturers to quickly and easily reconfigure their production processes in response to changing market demands.

Since the future is food robotics, it is more like the need of the hour that companies start researching in this domain. While the domain is getting saturated but creating a smart strategy to collaborate with technology partners can be one way forward.

You can read more about how collaboration fosters innovation in the food and beverage industry here.

Therefore, if you are interested to know in detail about the startups working on key trends in food robotics and how their goal aligns with yours – You can ask the experts with the simple form below.