The EV market is basically created by governments. The government-provided incentives are currently boosting the top electric vehicle companies to step up their innovation game. In 2015, electric car incentives by the Governments made up around 20% of total EV sales, however, the number went down to 10% in 2020 since the contribution from other sources increased.

Still, Government incentives are a big reason people buy electric vehicles, especially in China. The Chinese government took the most aggressive approach to making its people buy electric vehicles. China is the biggest emitter of fossil fuel carbon dioxide (CO2) emissions in 2020, accounting for 30.64 percent of global emissions, and the government is trying to change that.

The government did many things to make China a powerhouse in every aspect of electric vehicles, be it battery production, electric motors, charging stations, grids, etc. The government even funded local EV startups such as NIO, which is now one of the big Chinese EV companies around the globe.

Tesla also joined China as it saw the potential of the Chinese market, and it became the first company to make vehicle production in China without any joint venture. The Chinese government knew the influence that the EV giant would bring as it would give competition to the local players and motivate them to do better. As a result, the Chinese cars that were once always seen as the second choice are now considered good in consumers’ eyes, even in Europe and North America.

Today, China and Chinese EV companies are giving competition to global brands.

As a result, 2021 saw a 108% jump in EV sales compared to 2020. And Chinese saw a massive 155% jump in EV sales, with 3.3 million vehicle sales.

Tesla is still the top EV company with 13.84% of total EV sales in 2021, Volkswagen with 11.28%, and BYD with 8.84% following the lead. The 4th place goes to GM with 7.64%, and Stellantis with 5.74% share has 5th place. (Source)

The article will discuss the leading electric vehicle companies, their new inventions, and focus on tech areas.

Further, we also have a detailed EV Research Trends and Analysis Report that you can get by filling out the form below:

Here are the top 10 EV companies:

1. Tesla

Founded in 2003, it is an electric vehicle and clean energy company. Tesla aims to accelerate the world’s transition to sustainable energy by making electric vehicles more accessible to everyone. Over 275,000 Model S, Model X, and Model 3 cars are now on the road globally. Tesla also produced endlessly scalable energy solutions to ensure a sustainable energy future: Powerwall, Powerpack, and SolarRoof.

Tesla is a large electric-vehicle producer in the United States, but rivals are beginning to steal into its market share as demand for electric vehicles grows. The company’s market share of all-electric vehicles is predicted to fall to 56% by 2021. According to projections, Tesla’s market share of all-electric vehicles in the United States will reach 20% by 2025.

Which New Technologies is Tesla Working on?

Lithium-Iron-Phosphate (LFP) Battery – In 2021, Tesla announced that it will switch the battery chemistry used in all of its standard-range electric vehicles to one with a lithium-iron-phosphate (LFP) cathode. The move is likely a way for the company to increase profit margins on its fully-electric vehicles without raising vehicle prices. There are both good and negative trade-offs with LFP. It is far less expensive and does not require any nickel or cobalt. It’s also more stable, making it safer. One significant disadvantage is that the cells are less energy-dense, providing less range for the same weight as conventional cells. Cold weather also has a greater impact on them. (Source)

Supercharger – In 2021, the EV giant announced a trial program for non-Tesla electric vehicles to access its supercharger network. With ten Supercharger stations, it began a non-Tesla Supercharger trial in the Netherlands in November 2021. Tesla has been committed to rapid network growth since the first superchargers were installed in 2012. It now has over 25,000 superchargers in operation throughout the world. The company uses the CCS standard in Europe, therefore, any EV with a CCS connector may use the stations without needing an adaptor, which will be necessary when Tesla launches the Supercharger network in North America. (Source)

J1772 Gen 2 Wall Connector – In 2021, the company unveiled a new home charger with a J1772 plug that will operate with all-electric vehicles in North America, not only Tesla. The J1772 Gen 2 Wall Connector offers up to 9.6 kW (40 amp) power output for a single vehicle, as well as a 24-foot (7.3 meters) cable length, several power settings, and a flexible indoor/outdoor design. (Source)

4680 Battery – In 2020, the EV manufacturer revealed the 4680 battery as part of their Battery Day celebrations. The 4680 battery is a cylindrical battery with a diameter of 46mm and a height of 80mm. Tesla anticipates that the 4680 battery will have a capacity five times that of the 2170 battery, a range increase of 16%, and a cost savings of 14%. Domestic automobile manufacturers primarily utilize prismatic batteries at the moment. With the rate at which the 2170 battery is replacing the 18650 battery, and assuming the 2170 battery remains the dominant battery in 2022, it will be gradually replaced by the 4680 battery by 2023 and fully replaced by 2024. (Source)

Tesla 14-50 Wall Connector – In 2019, the company unveiled a new Wall Connector with a NEMA14-50 plug, making it its first non-hardwired Wall Connector for a home charging option. For those who already have a NEMA 14-50 outlet near their parking place or who do not want to go through the hassle of establishing a hardwired charging station, Tesla recommends using the mobile connector on a NEMA 14-50 outlet. It claims that most of its vehicles can be charged at up to 40 amps (9.6kW). It supplies 40 amps (9.6kW) of electricity to all Model S, Model X, and Model 3 Long Range automobiles. When utilizing the 14-50 Wall Connector, Model 3 Mid and Standard Range cars will charge at 32 amps. (Source)

Which Technology Area is Tesla Focusing on?

The EV giant has always prioritized innovation. Tesla Motors’ first product is the Tesla Roadster, a high-performance electric sports automobile. However, the company aims to produce various vehicles, including reasonably priced family automobiles. This is due to their broader goal of accelerating the transition from a mine-and-burn hydrocarbon economy to a solar electric economy, which is the primary, but not sole, sustainable option.

The company’s approach is to join the market at the top end, where buyers are willing to pay a premium, and then push down the market as quickly as possible to larger unit numbers and cheaper pricing with each consecutive model.

As part of the lead-up to the company’s first-ever Battery Day for investors, the company has been touting new battery technology breakthroughs. Vehicles powered by lithium-ion batteries, which are also used in cell phones, are projected to make way for vehicles and trucks powered by lithium-iron-phosphate and other chemistries in the coming years. This reduces expenses, allows vehicles to go 400 miles or more between charges, and allows batteries to last up to a million miles. Tesla’s expenses are still being reduced, and the broad adoption of EVs is still a top priority for the company.

As Tesla develops next-generation electric vehicle batteries, the emphasis is shifting to lithium iron rather than lithium-ion, which has been the core chemical engineering science powering EVs to date. One of the most important goals is eliminating the rare, costly, and contentious metal cobalt from batteries. (Source)(Source)

Tesla Patent Insights

The company is well-known as a plug-in and battery electric passenger vehicle manufacturer. Aside from electric vehicles and batteries, Tesla produces and installs solar systems in the United States through its subsidiary SolarCity. The following are some of Tesla’s patent portfolio’s significant highlights:

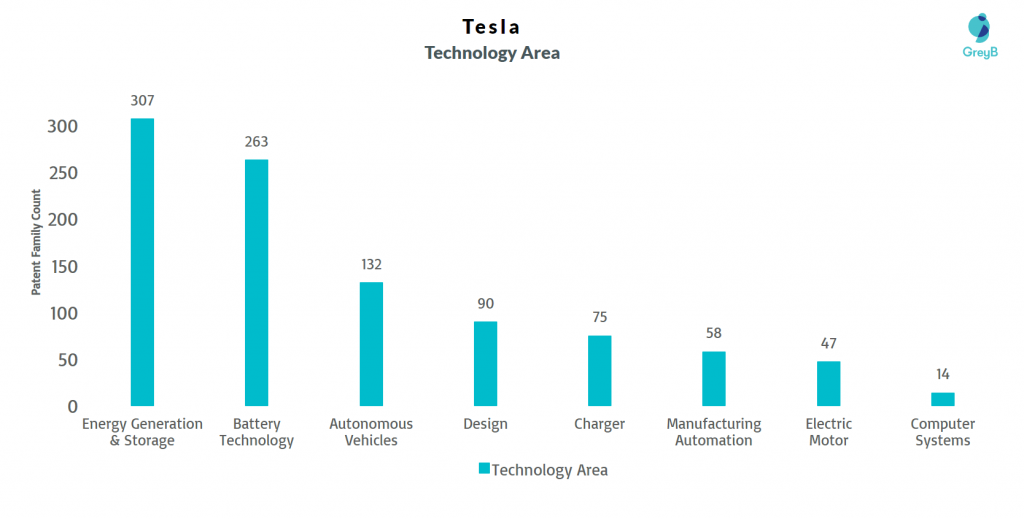

Technology Area Protected by Tesla Patents

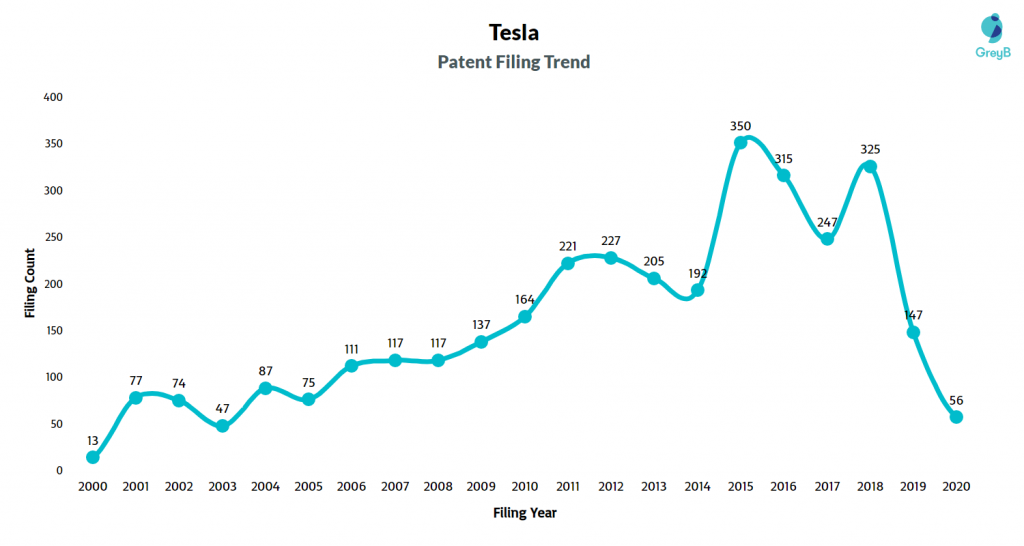

Patent Filing Trend

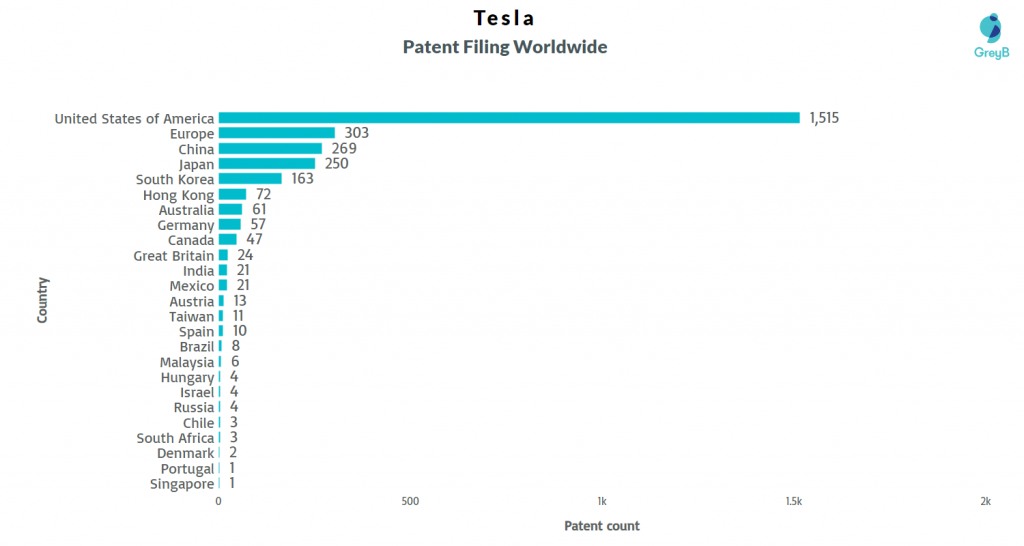

Countries in which Tesla Filed its Patents

2. Volkswagen

Volkswagen, a German automaker, has a research and development center, parts and vehicle processing, parts distribution centers, sales, marketing, and service offices, financial service centers, and a state-of-the-art manufacturing facility in Chattanooga, Tennessee, among its operations in the United States.

In 2017, Volkswagen stated its intentions to focus heavily on electric cars, with a target of launching at least 30 EV models by 2025 and having EVs account for 20% to 25% of their entire annual sales volume (2-3 million). By 2030, the company hoped to have electric versions of all of its vehicle models, at a cost of €20 billion, plus €50 billion for battery purchases. In 2020, Volkswagen stated that it will invest $86 billion in electric and self-driving automobiles over the next five years. (Source)(Source)

New Inventions and Technologies

Unified Battery Cells – Volkswagen aims to begin rolling out a new unified prismatic cell design for its batteries in 2023. The new design will be used across the automaker’s brands. By 2030, Volkswagen hopes to have this unified cell architecture powering up to 80% of its electric vehicles. The objective is to get the cost of battery manufacturing below $100 per kWh, which most experts believe will bring EVs closer to the pricing of gasoline-powered vehicles. Volkswagen intends to further reduce costs through more efficient manufacturing and a comprehensive recycling procedure. The manufacturer intends to eventually lower battery prices by up to 50% in the entry-level category and up to 30% in the volume segment. (Source)

Volkswagen Naturstrom Connect – Volkswagen Naturstrom Connect is a smart home electricity tariff designed specifically for Volkswagen electric and plug-in hybrid vehicle drivers. Volkswagen designed the Naturstrom Connect tariff by directly linking the energy tariff with electric car charging, which is managed via the Naturstrom Connect app.

The client permits dynamic response of their electric vehicle charging to the grid’s carbon intensity in return for one reward point for each qualified smart charge exceeding 7kWh. Each time the user earns 10 points, they will receive a €5 ($6) bill credit, which will be applied to their annual power payment. The user may save up to €100 ($114) per year and can track their energy consumption, carbon reduction, and energy cost savings over time. The Volkswagen Naturstrom Connect app will be seamlessly integrated with Volkswagen cars via the owner’s Volkswagen ID, offering a smooth login and linked mobility experience. (Source)(Source)

“As the supplier of Volkswagen Naturstrom®, we are opening up an entirely new business area for the Group. In the new world of mobility, the topics of energy and the automobile will become increasingly closely linked – we intend to grasp this opportunity.” – Karsten Miede, Project Manager for Volkswagen Naturstrom® and Head of E-Mobility Services with VW Kraftwerk GmbH. (Source)

Volkswagen’s Charging Ecosystem

Modular Electric Drive Matrix (MEB) – The future I.D. family vehicles are being developed based on the new Modular electric drive matrix (MEB). These are Volkswagens in various classes that have been developed as fully electric cars with ranges of up to 500 km or more. The MEB design will fundamentally transform electric vehicles and vehicles in general. The Modular Electric Toolkit eliminates all of the fossil-age baggage by being purpose-built for electric vehicles. This results in substantial modifications to electric Volkswagens’ body, interior, packaging, and engine characteristics. (Source)

ID.Charger – In 2020, Volkswagen debuted its ID home charging station and provided installation before the start of ID deliveries. It was designed with the ID.3 and ID. family in mind, but features a Type 2 connection, which is typical on European electric cars. All three ID.Charger variants come with a three-phase 11 kW power supply in Germany and other European markets. The ID.Charger produces up to 7.4 kW of charging power when connected in single-phase mode. The fixed charging wire is 4.5 meters long. Additionally, a 7.5-meter charging cable is offered as an option.

The ID.Charger is compatible with all-electric cars equipped with type-2 connectors. This applies to nearly all conventional electric vehicles sold in Europe, including the e-Golf and e-up!

The ID.Charger is available in three versions and starts at €399 ($450). (Source)(Source)

- ID.Charger – The basic level version, priced at €399, combines high-end performance with an affordable charging option. Simple operation, a permanently attached type 2 charging connection, and a charging capability of up to 11 kW all contribute to the convenience of charging at home. The modern design complements the new ID.3. Additionally, the Wallbox is small and robust, with built-in DC residual current protection for optimal safety.

- ID.Charger Connect – Charging becomes digital and intelligent with the clever ID.Charger Connect. The Wallbox may be linked through W-LAN or LAN to the home network and smartphone. Additionally, a cellular network (LTE) connection is possible. Customers can monitor consumption and charging status and take advantage of convenient features such as app management, remote maintenance, access control through credit cards, and automatic software upgrades. The ID.Charger Connect is priced starting at €599.

- ID.Charger Pro – The ID.Charger Pro is the top-of-the-line Wallbox model, with an integrated energy meter for kilowatt-hour invoicing in addition to the digital capabilities and standard LTE module. Thus, it increases openness regarding power use and facilitates easier invoicing between corporate car drivers and employers, for example. The ID.Charger Pro is priced starting at €849 upon launch. The cost of LTE data is already included for the duration of the box’s life. (Source)

“The ID. Charger doesn’t just look smart, it is smart, too. No other wallbox on the market offers so much high tech at such an attractive price.”

– Martin Roemheld, Head of Mobility Services at the Volkswagen brand.

“In the past, buying a wallbox was often a tiresome and long-winded exercise for customers. We want to change that and are offering a single-source solution for the ID. Charger – from purchase and installation through to commissioning.”

– Peter Diekmann, Key Account Manager at the Volkswagen subsidiary Elli who is responsible for the ID. Charger. (Source)

ID.Charger’s Type-2 Connector (Source)

ID.Charger

We Charge – Volkswagen launched its own charging service in 2020 to correspond with the ID. family’s market release. Customers will be able to charge their electric vehicles at over 150,000 public charging stations located around Europe through We Charge. The We Charge charge card enables them to quickly and easily access these charging stations. Customers can choose from three distinct rates that include benefits such as exclusive access to the IONITY high-power charging network. We Charge is available for booking and usage beginning in mid-August. Thus, Volkswagen completes its charging infrastructure, which aims to make charging electric vehicles as convenient as feasible. (Source)

Tariffs are adapted to certain user groups:

- We Charge Free – There is no monthly price associated with the We Charge Free basic rate. It simply allows charging access via a single charging card – and is best suited to drivers who infrequently charge their electric cars at public charging stations.

- We Charge Go – The We Charge Go charges less for each charging procedure, making it the ideal solution for frequent users of public charging stations.

- We Charge Plus – The We Charge Plus rate is reserved for frequent drivers. For instance, in Germany, they pay just €0.30 per kilowatt-hour for IONITY, allowing them to make use of the pan-European high-power charging network at a very affordable price.

“As e-mobility increasingly takes to the road, public charging is becoming ever more important. With We Charge, Volkswagen is offering customers the right solution for swift, hassle-free travel in Germany and Europe – electric, eco-friendly, and above all, convenient.” -Richard van Tatenhove, Head of Digital Charging Services at Volkswagen.

Mobile Charging Robot – In 2019, Volkswagen Group Components introduced a fresh and innovative charging idea – Mobile Charging Robot. The mobile robot drives itself to the car that requires charging and connects with it after being activated through an app or V2X communication. The whole charging procedure takes place without any human contact, from opening the charging socket flap to attaching the plug to disconnecting. The charging robot’s compact design makes it suitable for usage in limited parking places with no charging infrastructure, such as underground parking areas. (Source)

“The mobile charging robot will spark a revolution when it comes to charging in different parking facilities, such as multi-story car parks, parking spaces, and underground car parks because we bring the charging infrastructure to the car and not the other way around. With this, we are making almost every car park electric, without any complex individual infrastructural measures.”

–Mark Möller, Head of Development at Volkswagen Group Components.

Volkswagen’s Future Vision of a Holistic Charging System

Focus Tech Area

In 2021, Volkswagen Group announced a big push to reduce the cost of making batteries for its electric vehicles to hasten the transition away from gas-powered vehicles. The company claimed it will lower battery production costs by up to 50%, establish several battery plants across the world, extend its network of charging stations, and eventually migrate to solid-state technology, which would slash costs and enhance efficiency. The ultimate objective is to develop electric vehicles with longer ranges and faster charging times, which are two of the most significant hurdles to broad EV adoption.

Volkswagen intends to increase the production of battery-powered vehicles by massively expanding its manufacturing area. By 2030, the company intends to have six battery cell production factories in Europe, which it would develop either alone or in collaboration with partners. In Salzgitter, Germany, Volkswagen Group Components established a new facility for cell research and development in 2021. As a result, the firm is growing its knowledge in battery technology and taking the next step toward creating and manufacturing its battery cells for electromobility. The Volkswagen unified cell is set to run off the Salzgitter assembly plant starting in 2025. In the future, approximately 250 specialists will perform research in the areas of cell growth, analytics, and testing in four facilities. Volkswagen is investing approx. €70 million in the facilities.

The second facility will be located in Skelleftea, Sweden; the third plant will be located in either Spain, Portugal, or France; and the fourth factory will be located in Eastern Europe. Schmall estimates that the facilities will have a capacity of 240 gigawatt-hours a year.

Volkswagen stated that it plans to have 18,000 public fast-charging outlets operational in Europe by 2025, a fivefold increase over the continent’s present status of EV charging. This will be done through a succession of smart alliances. Volkswagen announced a collaboration with oil giant BP and key European utilities Enel and Iberdrola to promote electric vehicle charging. The company also announced that it would have 17,000 public fast-charging stations in China and was on schedule to install 800 stations in the United States via its Electrify America subsidiary by 2021.

Volkswagen is relying largely on its Modular Electric Drive Matrix (MEB) architecture. This includes employing a chassis powered by batteries and electric motors that can be combined with a variety of vehicle and crossover bodywork to create a wide range of models. By 2028, 22 million vehicles will be on the road as part of the roll-out. MEB cars will be manufactured in eight locations: four in Germany, one in the Czech Republic, one in the United States, and one in China. There will be a strong emphasis on component sharing and cost reduction, including the utilization of all-steel platforms and reliable cost-effective raw materials for batteries. (Source)(Source)(Source)

“One of the most important future technologies for the Volkswagen Group is being driven forward here. Everything that is done at the Center of Excellence Battery Cell serves to provide customers of all Group brands with e-vehicles with the greatest possible range, charging performance, sustainability and safety.”

– Frank Blome, Head of the Battery Cell and Battery System Business Unit. (Source)

Volkswagen Patent Insights

Volkswagen’s technological power is highlighted by an ever-increasing percentage of patents for major cutting-edge areas. Driver assistance systems, automation, connectivity, as well as alternative driving systems, are elements of these disciplines. Volkswagen has filed 21,743 patents in the period 2009 to 2018. (Source)(Source)

3. BYD

Build Your Dreams (BYD) is the world’s leading provider of electric cars and batteries, as well as the leading provider of battery-electric buses, with over 35,000 buses in operation spanning 200 cities, 50 countries, and six continents.

The company is innovating zero-emission mobility and promoting environmental stewardship. BYD is a dominant player in electric vehicles, medium & heavy-duty trucks, forklifts, SkyRail (monorail), energy storage, and solar power production, in addition to zero-emission buses. (Source)

New Inventions/Technologies

Iron Phosphate Battery Solutions – BYD’s Iron Phosphate Battery Solutions are engineered to offer safe, steady, and dependable energy in most application areas. The Iron Phosphate chemical developed was initially intended for utility-scale energy systems with a service life of up to 30 years. The exceptionally steady and dependable battery chemistry can cycle thousands of times with no deterioration, making it perfect for operating battery-electric buses. (Source)

Blade Battery – the EV player has been working on the Blade Battery for several years and released it in 2020. The individual cells are stacked in an array before being put into a battery pack. The improved battery pack layout increases the battery space pack’s consumption by more than 50% when compared to other existing lithium iron phosphate block cells.

The Blade Battery generated zero smoke or flames after being penetrated during nail penetration tests, as well as its surface temperature approximately reached 30 to 60°C. A ternary lithium battery approached 500°C and aggressively burnt under the same circumstances, and although a standard lithium iron phosphate block battery did not overtly spew flames or smoke, its surface temperature reached hazardous levels of 200 to 400°C. The above means that EVs fitted with the Blade Battery are significantly less likely to burst into flames, even if they are badly damaged. Other rigorous test circumstances that the Blade Battery passed included being crushed, bent, heated in a furnace to 300°C, and overcharged by 260%. There was no fire or explosion as a consequence of any of them. (Source)

BYD e6 – The company’s 4.56m-long battery-electric crossover car e6 is the world’s most dependable electric vehicle. This car creates no emissions, is quiet and comfortable, easy to drive, and goes smoothly and powerfully thanks to BYD’s patented iron-phosphate battery. The BYD Iron Phosphate cell used in the BYD e6 and BYD ebus has survived several tests such as collision, spike, drop, scorching, short circuit, and so on. (Source)

Focus Tech Area

Lithium Iron Phosphate (LFP) battery – Since 2020, the non-cobalt trend in the power battery sector has increased, owing to attempts by the Chinese automaker. In May 2020, it released all-electric vehicles powered by lithium iron phosphate (LFP) batteries.

In October 2020, the company opened a manufacturing facility for their LFP blade battery in Ningxiang, Hunan Province, China. The battery has the potential to boost energy density by at least 30% while lowering raw material prices by 30%. (Source)

Blade Battery – The Chinese automaker plans to equip all future fully electric vehicles with its ‘Blade Battery’ by 2021. The Qin PLUS EV, Song PLUS EV, and 2021 versions of the Tang EV and e2 are the first new electric cars to have Blade batteries for the Chinese market. BYD’s innovative battery technology is standard on all four. It is expected to outperform all others in terms of durability and better safety. The BYD Han, as the first car, has already received the new battery technology since mid-2020. (Source)

Patent Insights

BYD Auto has 119 patents in its portfolio. It has been filing patents since 2008. The company has filed patents only in China. (Source)

4. General Motors

General Motors, an American multinational automotive manufacturing firm, has committed to producing 30 new worldwide electric vehicles by 2025, paving the road for an all-electric future. GM is well-positioned to design, engineer, and manufacture EVs in every style and price range. The company is fast establishing a competitive edge in batteries, software, vehicle integration, manufacturing, and customer experience.

GM’s comprehensive strategy focuses on charging capabilities at home and work, as well as improving public infrastructure, with the goal of providing customers with a seamless, easy, and cost-effective transition to electric mobility.

It also supports a grid powered by renewable energy sources, ensuring that the entire EV charging process is environment-friendly from the outset. Between 2020 and 2025, GM will invest $35 billion in EV and AV vehicle development, outpacing its investment in gas and diesel. (Source)

New Inventions/Technologies

Ultium Battery – GM’s newest battery, named Ultium, is said to be reaching a cost that is 90% cheaper, a threshold from where shifting away from internal-combustion engines can finally be economical. The manufacturer has vowed to launch 30 new EVs throughout the world by 2025. Heavy-duty trucks will be the only vehicles with tailpipes by 2035. The Ultium cell features a nickel-cobalt-manganese-aluminum combination and uses 70% less cobalt, which helps to reduce costs. A massive, pouch-type lithium-ion battery (about 23 by 4 by 0.4 inches) serves as the foundation for this layout. It weighs around three pounds. The 0.37-kilowatt-hour gross energy capacity of each cell is sufficient to move the first Ultium-powered vehicle, the massive 2022 GMC Hummer EV truck, a little over a half-mile. (Source)

62 kW, 255 kW, 180 kW Motors – In 2021, GM introduced its upcoming set of new electric motors which will power its future electric vehicles. The new electric motors include a 180 kW front-drive permanent magnet motor, a 255 kW rear- and front-drive permanent magnet motor, and a 62 kW all-wheel-drive assist induction motor. The new electric motors can be arranged in a variety of ways to meet a variety of power and torque requirements.GM claims that its new power electronics would have up to 50% less mass and space than those present in their existing EVs while providing up to 25% greater capabilities. (Source)

Ultium Drive – In 2020, General Motors launched its Ultium Drive electric powertrain systems, a new range of electric drive units that will power the vast majority of the automaker’s future EVs. Ultium Drive’s EV drive system portfolio includes five drive systems: assist all-wheel drive, front-wheel drive, rear-wheel drive, truck FWD/RWD, and truck dual motor. Depending on the application, these drive units, which include the motor(s), inverter, controller, and differential, will include one or more of three motors.

A primary front-wheel-drive motor, a primary rear-wheel-drive motor, and an all-wheel-drive assist motor will comprise the three Ultium Drive motor configurations. The new GMC Hummer EV truck and Cadillac Lyriq crossover are among the first items that feature Ultium motors and batteries. (Source)

“As with other propulsion systems that are complex, capital intensive, and contain a great deal of intellectual property, we’re always better off making them ourselves. GM’s full lineup of EVs should benefit from the simultaneous engineering of Ultium Drive. Our commitment to increased vertical integration is expected to bring additional cost efficiency to the performance equation.”

– Adam Kwiatkowski, GM Executive Chief Engineer, Global Electrical Propulsion. (Source)

Ultium Drive – Five Drive Units

Ultium Drive – Electric Motors

Ultium EV Chargers – In 2021, GM introduced the Ultium-Branded EV Chargers and Community Charging Program. The company plans to collaborate with its dealers to install more community charging stations and with CTEK to build new level 2 chargers. GM will offer up to 40,000 level 2 chargers (240V AC chargers) for installation in the United States and Canada as part of the community charging initiative.

The company will collaborate with its dealers and other local stakeholders to discover acceptable locations for the chargers to be installed. These will be universal chargers that can be used by any electric vehicle driver, independent of the manufacturer. Two 11.5-kW units and one 19.2-kW unit will be available. All are WiFi and Bluetooth enabled for simple management, including load balancing and over-the-air upgrades. The higher-priced 11.5-kW and the 19.2-kW units also contain customizable touchscreens and cameras. (Source)

Ultium Standard Wall Mounted Charger

Focus Tech Area

In 2021, General Motors CEO Mary Barra declared that the business would stop producing gas-powered vehicles and transition to all-electric vehicles by 2035. GM established the Automotive Manufacturing Electrical College (AMEC) to retrain professionals to work on EVs. The purpose is to teach existing and future staff to work on changing electrical systems in GM cars in the future.

GM is speeding up plans to develop two additional battery cell manufacturing factories in the United States by the middle of the decade to complement the Ultium Cells LLC operations now under construction in Tennessee and Ohio. More information regarding these new U.S. factories, including their locations, will be released.

General Motors announced a cooperative development partnership with lithium metal battery developer SolidEnergy Systems for the next-generation Ultium battery chemistry, in 2021. The lithium metal battery with a shielded anode from GM will be affordable, high-performing, and energy-dense. GM is collaborating with various creative firms and making investments that will help the company to expand swiftly in order to speed Li-Metal battery commercialization.

Years ago, GM Ventures made an early investment in SES, a pioneer in Li-Metal technology research, development, and production, as well as AI-powered battery management software to maximize performance and safety. The 2015 investment marked the beginning of a strong collaboration between SES and General Motors’ research and development arm.

General Motors announced the Wallace Battery Cell Innovation Center in 2021, a brand-new facility that would dramatically increase the company’s battery technology activities and hasten the development and commercialization of longer-range, more economical electric car batteries. The Wallace Center will be located on the property of GM’s Global Technical Center in Warren, Michigan.

Building on nearly a decade of advanced battery development at GM Research and Development, the facility will play a crucial role in supporting GM’s vision of an all-electric future and paving the way for the broad adoption of EVs. GM will also use the facility to incorporate the work of GM-affiliated battery inventors, assisting the firm in meeting its stated objective of at least 60% reduced battery prices with the next generation of Ultium. The Wallace Center is presently under development and will be finished by mid-2022.

GM announced in 2021 that it will deploy up to 40,000 electric-vehicle charging stations in the United States and Canada as part of a $750 million commitment to expand its position in the fast-developing market. The business stated that it will extend home, workplace, and public charging infrastructure using its Ultium Charge 360 ecosystem, with an emphasis on deploying them in rural and urban regions with limited access to boost EV adoption. (Source)(Source)(Source)(Source)(Source)(Source)(Source)

“We are moving quickly to bring new EVs to market that customers will love. We know how important the charging ecosystem is for drivers, one that includes access to convenient and reliable public fast charging. Our relationship with EVgo will bolster the public fast-charging network available to EV customers ahead of increased market demand and reinforce our commitment to an all-electric, zero-emissions future.”

– Mary Barra, GM Chairman, and CEO. (Source)

Patent Insights

According to corporate records, GM’s patent history demonstrates an emphasis on advancements in battery technology, packaging, and processing, with some of them targeted to help enhance the battery’s energy and extend vehicle range between charges. (Source)

“Patents are an indicator of the potential for the GM enterprise to innovate. Thriving companies have a track record of creating and commercializing innovation, and we are striving every day to discover technological breakthroughs that create tangible benefits for our customers around the globe.”

– Jon Lauckner, GM Chief Technology Officer, Vice President of Global R&D, and President of GM Ventures. (Source)

Patent Trends

5. Stellantis

A global automotive manufacturing business founded in 2021 by a 50-50 cross-border merger of Fiat Chrysler Automobiles and PSA Group. Stellantis provides a wide range of passenger automobiles, including luxury, premium, and mainstream models. As well as pickup trucks, SUVs, and light commercial vehicles, and specialized mobility, finance, and parts and service brands. It intends to have 39 electric car variants on the market by the end of 2021. (Source)(Source)

New Inventions/Technologies

Cobalt-Free Lithium-Ion Battery – The company authorities announced the development of two new lithium-ion battery chemistries, one of which would be free of the expensive cobalt. Battery packs will be able to store energy ranging from 37 to more than 200 kilowatt-hours. The STLA Small architecture has a range of up to 300 miles while the STLA Large and STLA Frame platforms have a range of up to 500 miles per charge. Charging times are predicted to be reduced to as low as 10 minutes for an additional 200 miles of range. (Source)

Solid-State Batteries – Stellantis and Factorial Energy signed a cooperative development agreement in 2021 to enhance Factorial’s high-voltage traction solid-state battery technology. Stellantis will also make a strategic investment as part of the arrangement. The company revealed its goal of introducing the first competitive solid-state battery technology by 2026 during its EV Day program in July 2021. (Source)

“Our investment in Factorial and other highly recognized battery partners boosts the speed and agility needed to provide cutting-edge technology for our electric vehicle portfolio. Initiatives like these will yield a faster time to market and more cost-effective transition to solid-state technology.”

– Carlos Tavares, Stellantis CEO.

Focus Tech Area

In 2021, Stellantis proposed a complete electrification plan that focuses on delivering innovative, class-leading automobiles for the company’s famous brands while employing in-house knowledge, partnerships, and joint ventures to offer sophisticated technology at accessible pricing.

The company will provide a comprehensive suite of solutions for private, commercial, and fleet clients to ease the ownership process. Efforts will include delivering day-to-day smart charging offers utilizing green energy sources, using existing partnerships to extend charging possibilities, and speeding smart grid use.

To begin, the company wants to deploy four battery-electric platforms across its brands, with ranges ranging from 300 to 500 miles on a full charge, as well as a family of three electric motor modules. Stellantis’ four new electrified platforms are planned to support the manufacturing of 2 million automobiles per year. It plans to invest more than €30 billion in electrifying its vehicle range between now and 2025.

Stellantis also intends to have uniform battery packs across all brands, as well as a quick charging capability of 20 miles per minute. Its electrification strategy spans the full value chain. The firm’s EV battery sourcing approach is to acquire over 130-gigawatt hours (GWh) of power by 2025 and over 260 GWh by 2030. It also intends to build five Giga factories in North America and Europe. The Giga factories will meet the demands for EV batteries and components, which will be supplemented by further supply contracts and partnerships to accommodate overall demand.

The company has signed memorandums of understanding (MOUs) with two lithium geothermal brine process partner organizations in North America and Europe to ensure a sustainable supply of lithium, which has been identified as the most critical battery raw material in terms of availability, as well as the ability to implement lithium into the supply chain once available.

Stellantis’ technological experience and production synergies will bring down battery prices in addition to sourcing techniques. The firm seeks to optimize the entire value of the battery life cycle through repair, remanufacturing, second-life usage, and recycling, as well as to assure a sustainable system that prioritizes customer requirements and environmental considerations.

The company has EVs on the way, but specifications and timings for their arrival remain unclear, with the majority expected to arrive in the middle of the decade. (Source)(Source)(Source)

Patent Insights

Stellantis has filed several patents in diverse fields, including new mobility solutions such as full electric, hybridization, and hydrogen, as well as digital, communication, and innovative applications (shared vehicles, services).

Furthermore, the company has filed patents for Car-to-X infotainment connectivity/applications, remote diagnosis, on-board software updates, human-machine interfaces, improved E-call features, and digital cockpit.

As the company is a 50-50 cross-border merger of Fiat Chrysler Automobiles (FCA) and PSA Group, therefore, the patents of FCA can be applied to Stellantis. (Source)

6. Hyundai-Kia

A South Korean multinational automobile manufacturer located in Seoul. In 1988, the business began developing flexible-fuel vehicles (FFVs). Hyundai produced its first fully electric vehicle, the Sonata Electric Vehicle, in 1991. In 2008, it began mass-producing hybrid electric automobiles.

New Inventions/ Technologies

Electric-Global Modular Platform – Hyundai Motor Group launched its new Electric-Global Modular Platform (E-GMP), a specialized battery electric vehicle (BEV) platform, in December 2020. The E-GMP would support a variety of dedicated new BEVs beginning in 2021, including Hyundai Motor Company’s IONIQ 5; Kia Motors Corporation’s first dedicated BEV, which would be introduced in 2021; and a number of additional vehicles. E-GMP, which has been designed particularly for BEVs, offers many benefits over the Group’s previous platforms, which have all been designed primarily to accept internal combustion engines. Better development flexibility, greater driving performance, increased driving range, reinforced safety measures, and additional interior room for people and baggage are among the benefits. (Source)

Next-Generation Solid-State Battery – Hyundai Motor and Kia has collaborated with the US business Factorial Energy to develop solid-state battery technology in November 2021. Factorial Energy has developed ‘FEST’ technology, a solid-state battery technology that may enhance driving distance by 20-50% while also boosting the safety of electric vehicles when compared to conventional lithium-ion batteries. Hyundai Motor and Kia intend to create interconnected techniques that span not just solid-state battery cells, modules, and systems, but also mass manufacturing and installation procedures. (Source)(Source)

Focus Tech Area

Hyundai and LG Energy Solution Ltd. commenced construction of an electric vehicle (EV) battery cell factory in Indonesia in September 2021 to achieve worldwide leadership in the battery electric vehicle (BEV) industry. The factory is projected to generate 10-GWh of NCMA lithium-ion battery cells every year, which is enough to power more than 150,000 BEVs.

Furthermore, the plant will be prepared to boost its manufacturing capacity to 30 GWh in order to satisfy the growing demand for future BEVs. Furthermore, the plant will be prepared to boost its manufacturing capacity to 30 GWh in order to satisfy the growing demand for future BEVs. (Source)

Further, Underwriters Laboratories and Hyundai announced a memorandum of agreement in 2021 to assist advance the safe implementation and usage of used battery energy storage systems (SLBESS).

The two said that they would work together on SLBESS activities such as safety testing and assessment, a product demonstration project in North America, and evaluation process development. They said that they want to exploit their global reach to increase SLBESS market acceptance.

Second-life batteries are frequently electric car batteries that no longer match the criteria of automotive usage but are still useful as grid-connected energy warehouse systems. (Source)

Patent Insights

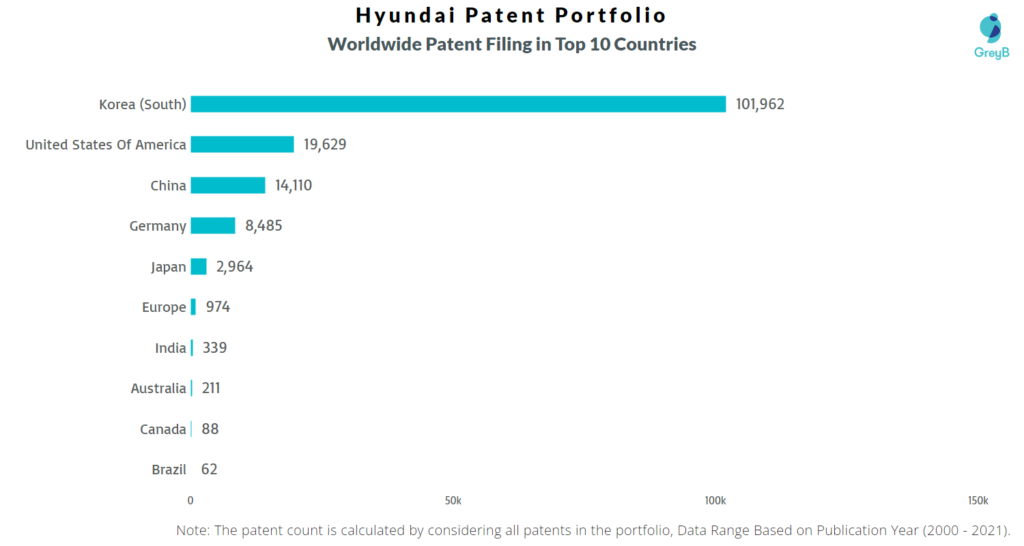

Hyundai has around 149,551 patents, 81,002 of which have been granted. Hyundai submitted the most patents in South Korea, followed by the United States and China. South Korea appears to be the primary concentrated R&D hub, as well as Hyundai’s founding nation. (Source)

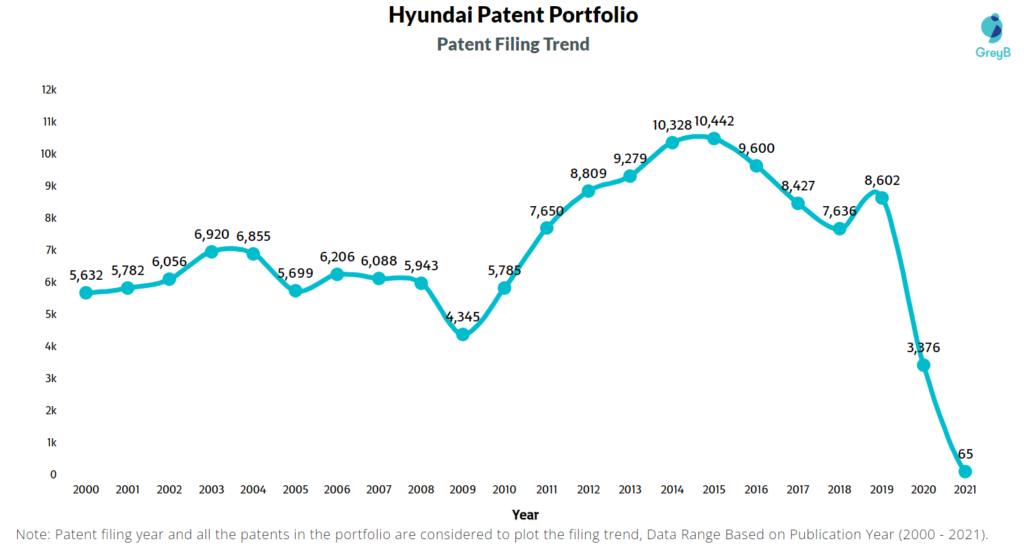

Patent Filing Trend

Top Countries in which Hyundai Filed Patents

7. BMW

The BMW Group, via its four brands BMW, MINI, Rolls-Royce, and BMW Motorrad, is a premium producer of automobiles and motorcycles, as well as a premium provider of financial and mobility services. The BMW Group’s manufacturing network consists of 31 production and assembly plants in 15 countries, and the firm has a global sales network in over 140 countries. The first hybrid BMW was the BMW ActiveHybrid 7, which debuted in 2010, and the BMW i3, which debuted in 2013, was the company’s first mass-production electric vehicle.

New Inventions/ Technologies

Hydrogen Fuel Cell Technology – The BMW Group has been working on a hydrogen fuel cell-powered vehicle, the BMW i-Hydrogen NEXT. There is a significant difference between hydrogen fuel cell cars and other electric cars: hydrogen automobiles generate their own power. As a result, unlike entirely electric or plug-in hybrid vehicles, the car is not powered by a built-in battery which can be charged by an additional power supply.

In fuel cell design, hydrogen interacts with oxygen in the fuel cell through a procedure termed reverse electrolysis. The hydrogen is supplied through one or more tanks integrated within the FCEV, while the oxygen is supplied by the surrounding air. The sole byproducts of this process are electrical energy, heat, and water, which are expelled as water vapor via the exhaust.

Therefore, hydrogen-powered automobiles have zero emissions in their immediate area; we’ll discuss more on that in a moment. The energy produced by a hydrogen engine’s fuel cell may be used in one of two ways: to run the FCEV directly or to recharge a battery. Since it is continually recharged by the fuel cell, this battery, known as a Peak Power Battery, is substantially smaller and hence lighter than the battery of a completely electric vehicle. (Source)

“In Germany, the European Union and other major regions of the world, lawmakers have recognized the significance of green hydrogen for the energy system of the future. We greatly welcome these various initiatives! For use on roads, the most important aspect is to expand fueling station infrastructure early on in a way that meets the needs of both utility and passenger vehicles. Depending on how conditions develop, hydrogen fuel cell technology can become another pillar in the BMW Group’s drivetrain portfolio. Since 2013 we have been cooperating successfully with Toyota in this field and will present the second generation of our hydrogen fuel cell drivetrain in a small series of the BMW i Hydrogen NEXT based on the BMW X5.” (Source)

– Oliver Zipse, Chairman of the Board of Management of BMW AG

eDrive Technology – The innovative BMW eDrive technology, which is present in all BMW i-models and plug-in hybrids, is made up of an electric engine, an elevated lithium-ion battery, and an advanced power management technology. The electric motor allows for zero-emission mobility. Automobiles can go long distances without consuming any gasoline. For example, the X5 xDrive40e can go up to 30 kilometers using no petrol. All eDrive cars use a high-performance lithium-ion battery to carry the energy and a built-in cooling mechanism to maintain the unit at the right temperature. This contributes to increased productivity and serviceability. Intelligent energy management is required to ensure that everything runs smoothly. (Source)

Focus Tech Area

eDrive Zones – The BMW eDrive Zones digital service is currently standard on a variety of BMW Group plug-in hybrid cars. BMW eDrive Zones initiate an automated switch for complete electric operation as soon as the vehicle enters a defined region, such as a low-emission zone. The BMW eDrive Zones service uses GPS-based geo-fencing technology. The transition to entirely electric driving is automatic. When the service is enabled, the Control Display visually highlights each accessible eDrive Zone on the navigation map. (Source)

BMW Group is the first automobile manufacturer to employ GPS geofencing technology in London and Birmingham. The eDrive Zones service, which covers the same geographic region as the TFL Congestion Charge/ULEZ zone in London, employs geofencing technology through GPS inside the vehicle’s navigation system. The service in Birmingham would cover the city’s proposed Clean Air Zone, which is set to go into effect in 2021. (Source)

Patent Insights

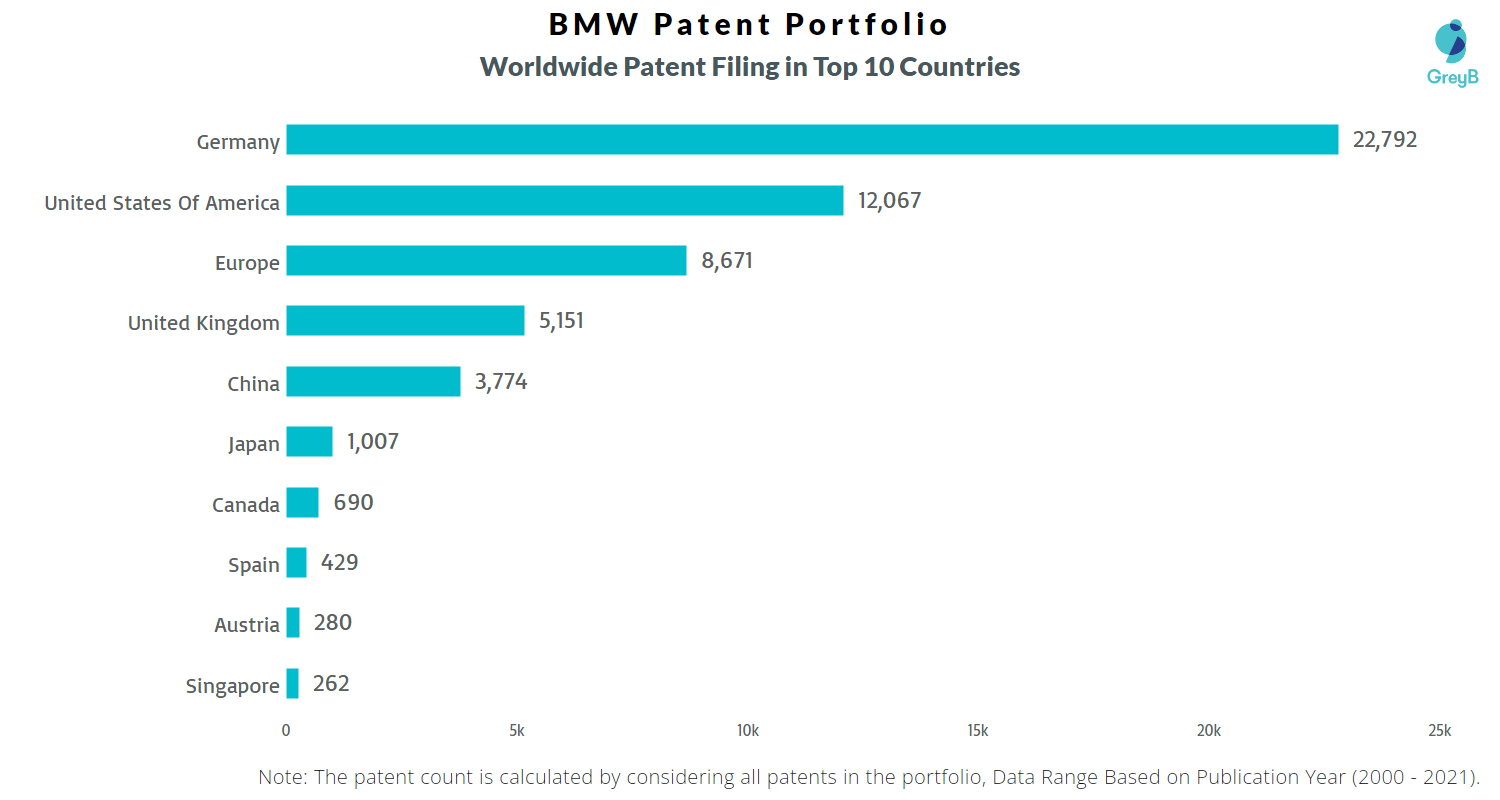

Since its founding, the BMW Group has depended on innovation as one of its key success factors. BMW holds a total of 61,964 patents worldwide, 23,165 of which have been awarded. BMW has filed the most patents in Germany, followed by the United States and Europe. (Source)

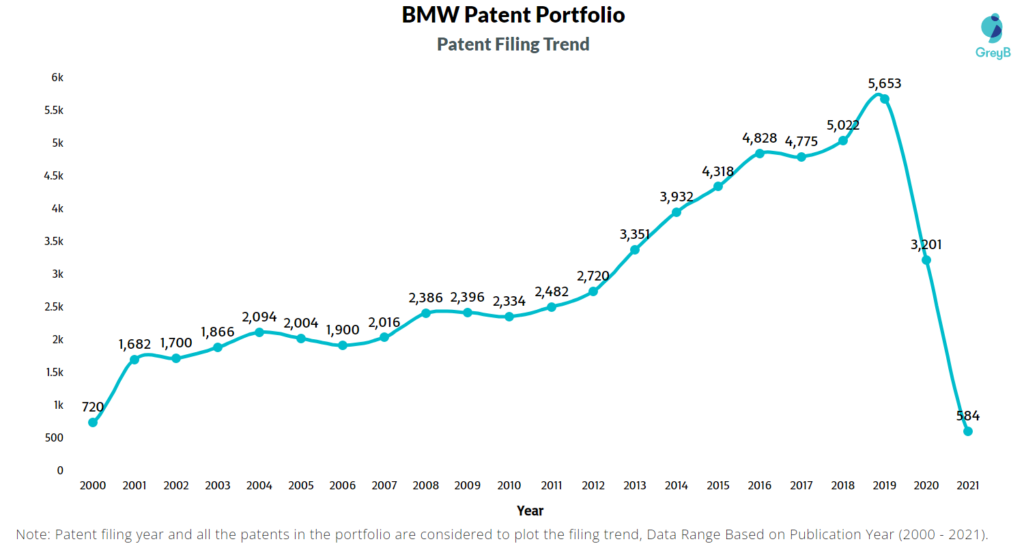

Patent Filing Trend

Top Countries in which BMW Filed Patents

8. Nissan

Founded in 1933, Nissan is a global automobile manufacturer that offers automobiles under the brands such as Nissan, INFINITI, and Datsun. The electric vehicle specialist has been one of the first automakers to enter the market with the Leaf hatchback in 2010.

The company proclaimed its ambition to provide affordable electric vehicles to the public throughout the world when it introduced the all-electric LEAF in 2010. Presently, Nissan North America, Inc. aims for over 40% of its U.S. automobile sales to be entirely electric by 2030.

The firm has promised a $17.6 billion (¥2 trillion) investment over five years to introduce 20 electric cars to guarantee it remains associated with EVs. To encourage this, the automaker revealed four reportedly electrified concept vehicles- an SUV, truck, convertible, and a compact crossover that may be the next-generation Nissan Leaf. The name of Nissan’s expedited electrification ambitions is Ambition 2030, and it will see the introduction of 23 new vehicles for the Nissan and Infiniti brands, 15 of which will be battery-electric versions. (Source)(Source)

New Inventions/Technologies

e-4ORCE AWD Technology – The company’s latest electric powertrain technology, e-4ORCE, has a balanced, consumer-focused approach that will transform the way the all-wheel drive is used. Nissan e-4ORCE has two electric motors that respond to driver input with perfect accuracy, processing at three times the speed of a blink of an eye. Instant torque is given to all four wheels for optimal control and a strong connection to the road.

Torque vectoring allows reacting to changing conditions by adjusting the torque transmitted to each wheel. Nissan e-4ORCE optimizes line tracing, chassis control, and steering accuracy. Every engine and wheel brake is continually adjusted for exceptional handling in all situations. As e-4ORCE controls the brakes on each wheel, regenerative braking allows the two engines to collaborate to minimize pitch and dive and provide a smoother, more level drive. Nissan’s e-4ORCE AWD technology has the potential to transform the future of AWD automobiles. (Source)

“This technology offers a new level of control. New for Nissan, new for EVs. e-4ORCE control technology is the combination of our know-how of all-wheel drive and chassis control technology and our EV development expertise. e-4ORCE is not a successor of one, but an evolution of many. e-4ORCE’s control technology stands out from other EV all-wheel systems available today. We performed extensive fine-tuning to deliver precise performance that supports the driver’s intentions for an enjoyable drive under a wide variety of conditions.”

– Ryozo Hiraku, Expert Leader of Nissan’s Powertrain and EV Engineering Division. (Source)

e-POWER System – In 2021, Nissan claimed a milestone in engine efficiency, achieving 50% thermal efficiency with its next-generation e-POWER system, which is currently in development. The e-POWER system makes use of an onboard gasoline engine to power the e-battery powertrain’s pack. The e-POWER system’s e-powertrain is powered by an onboard engine that acts as a specialized electricity generator. The engine is restricted to its most efficient range of operation by properly controlling the engine’s electrical generation and the battery’s charge. Nissan’s design and development of an engine especially for e-POWER maintain this path of efficiency in the next generation e-POWER system. (Source)

“In pursuit of carbon neutrality across our product lifecycle by 2050, Nissan aims to electrify all new models launched in major markets by the early 2030s. Nissan’s electrification strategy promotes the development of e-powertrains and high-performance batteries for EVs, with e-POWER representing another important strategic pillar.”

– Toshihiro Hirai, Senior Vice President of The Powertrain and EV Engineering Division, Nissan

The Technology of e-POWER

e-Pedal – When the second-generation LEAF was introduced in 2018, it continued to revolutionize driving with a new technology dubbed e-Pedal, which enables the driver to manage the vehicle’s acceleration and deceleration with a single pedal. The all-new Nissan Qashqai e-POWER (scheduled to be on sale in 2022) will also feature the innovative e-Pedal technology.

The e-Pedal enables the driver to accelerate, decelerate, and stop the vehicle with a single pedal, therefore increasing the vehicle’s economy by eliminating reliance on the conventional braking system. Contrary to its name, the e-Pedal is not a separate pedal; rather, it is a system that converts the accelerator with the flip of a switch on the center console. Once enabled, the driver can speed the car normally by pressing the accelerator pedal, but when the driver releases the accelerator, the automobile will decelerate until the driver comes to a complete stop. (Source)

Working of an e-Pedal

ProPILOT 2.0 – The most recent version, ProPILOT2.0, employs cutting-edge technology to assist drivers in navigating through traffic with ease. It debuted in Japan on all hybrid variants of the thirteenth generation Skyline and also appeared on the 2021 Nissan Ariya.

The improved system, which was designed especially for ramp-to-ramp highway use, employs the vehicle’s navigation and a complex set of cameras, radars, and sensors to provide Level 3 autonomous driving while traveling in a single lane, among other capabilities.

ProPILOT2.0 operates while approaching a highway and following the navigation system’s programmed path. The driver is notified of the system’s availability by audio cues and visual indicators. Once activated through the specific button on the steering wheel, it will utilize the 360-degree sensor system to assist the driver in navigating the vehicle along a predetermined path on specified highways.

The 360-degree sensing system detects lane markings, signs, and approaching vehicles using seven cameras, five radars, and twelve sonar sensors. It’s a step toward the eventual goal of completely driverless vehicles, and it allows drivers to unwind on lengthy journeys, provided the route and weather conditions are ideal. (Source)

“The announcement for the Nissan Skyline is a system that can only be offered in Japan right now because of the availability of highly detailed 3D mapping that is required for its operation. Mapping is being carried out in other parts of the world to the same standard, and will take time for this to be achieved.”

– Kyle Bazemore, Director Corporate Communications at INFINITI Motor Company (Division of Nissan). (Source)

ProPILOT 2.0 – Sensing Data in the System

ProPILOT 2.0 Vehicles – Onboard Cameras, Radars, Sonars, GPS, and High-Accuracy 3D Map Data

Focus Tech Area

Nissan has always prioritized the research and commercialization of breakthrough technology that rivals cannot match.

Recently, the company has been focusing on research and development that focuses on three main areas of technology. These are referred to as three pillars of technology, namely Electrification, Autonomous Drive, and Connected Car & Service. In addition, Nissan is also focussing on the unique value of starting from scratch.

To be carbon neutral across the lifecycle of a product by 2050, Nissan wants to make all of its new cars and trucks electric by the early 2030s. It was the first company to research and develop batteries and motors for electric cars. The automotive giant has also put a lot of different technologies on the market to make electric cars more safe and easy to use. These include things such as how electric cars are used and how they affect the environment. It has helped set the standards for charging facilities and their deployment. It has also offered the Vehicle-to-Home system and a battery reuse business through 4R Energy. For electrification to become more widespread, the company needs to deal with the challenge of new battery technologies and help its research and development.

Another part of the strategy for electrification is e-POWER. The system will make it even easier to cut down on the amount of CO2 that vehicles produce. Also, Nissan gives its customers safe and secure ways to get around by taking advantage of the power of the motor drive.

Connected technology that connects to cloud services or smartphones and provides a wide range of services for the vehicle’s occupants has been the subject of many technical transformations by Nissan for a long time now.

Nissan unveiled a green vehicle plan for China in 2021. The new car, X-Trail, is driven by a fuel-sipping three-cylinder, petrol-powered turbo engine. In addition, Nissan would focus on electric hybrids with fuel-efficient petrol engines and battery-electric cars in China.

It also plans to use funds from vehicles that have ProPilot today to build out the next generation of features for vehicles that have it tomorrow. (Source)(Source)(Source)

“Though the evolution of automotive technologies today is more competitive than ever, we have an innate sense that we need to persist. If we lose out in terms of technology, we’re going to lose out in terms of business. Even with limited resources, we’re going to continue putting a hammer to the rock.“

– Takao Asami, Nissan Senior Vice President.

Patent Insights

According to Compeete, Inc., Nissan’s patent filings include 2079 distinct subjects and applications. (Source)

Nissan Patent Trends

9. Daimler (Mercedes-Benz Group)

Daimler AG is a German automaker that designs, manufactures, and distributes vehicles, trucks, vans, and buses. Finance, leasing, fleet management, insurance, and mobility services are also available through the organization. Mercedes-Benz, smart, Freightliner, Western Star, FUSO, BharatBenz, Thomas Built Buses, and Setra are among the names under which Daimler offers its products.

Daimler is sticking to its three-lane drive system approach, which includes electric cars, hybrid models, and combustion engines, to achieve locally emission-free driving. Under the new EQ product and technology brand, the business is pursuing a comprehensive approach to electrification. Daimler intends to invest more than €40 billion ($47 billion) by 2030 to remain competitive in an all-electric vehicle market. (Source)(Source)(Source)

New Inventions/Technologies

Mercedes me Charge – In 2021, Mercedes-Benz introduced a new charging ecosystem named Mercedes me Charge. The new Mercedes me Charge function Plug & Charge makes charging the EQS at compatible public charging stations even easier: charging begins as soon as the charging cable is plugged in; no additional customer verification is necessary.

The charging wire connects the automobile to the charging station. The “Mercedes me” Charge platform also collaborates with the vehicle’s navigation system. Using this it can plan the quickest and most convenient route for drivers. Routes that include the charging stops. It also reacts dynamically in real-time to traffic jams, changes in driving style, and even how busy a specific charging station will be. Mercedes-Benz has a patented Green Charging technology. The patent guarantees an equivalent amount of renewable energy supplied into the grid for charging electric vehicles. (Source)(Source)

Wireless Charging of Hybrid and Electric Vehicles – In only a few years, Daimler will equip the next generation of Mercedes-Benz electric and hybrid vehicles with inductive charging technology. It has established an agreement on the development and deployment of standardized technologies in this area. Inductive charging of the battery makes electric vehicles and plug-in hybrids even more convenient to use. This significantly simplifies the battery charge.

The user no longer needs a charging cord between the vehicle and the wall socket to replenish the car’s energy storage unit. In the future, the vehicle will just drive over a flat station to begin non-contact charging — whether at home, work, or even on the road during a layover. The system is composed of two components: a secondary coil installed on the vehicle’s floor and a floor plate with an integrated main coil put beneath the vehicle – for example, on the garage floor. (Source)

Mercedes-Benz Wallbox Home – The Mercedes-Benz Wallbox Home is a charging station with a charging cable included and a charging capability of up to 22 kW. It enables charging several times quicker than a standard domestic power socket. The charging process is shown by a multi-colored LED indicator light on the wallbox. During the charging process, the charging wire is locked, making disconnection impossible. The limitation of access through a key switch also safeguards against unauthorized usage. (Source)

Charge&Pay for Mercedes-Benz App – The Charge&Pay for Mercedes-Benz app makes it simple to locate and use nearly all publicly accessible and internet-enabled charging stations – and it also provides a handy method of payment. One-time registration and a PayPal account are required. People may then use their smartphones to find charging stations, verify their availability, and control the charging process. It is quick and easy. The payment procedure is also handled directly and securely via the app. The software is free to download for iOS and Android smartphones. (Source)

Focus Tech Area

By 2025, the European Commission expects that electric vehicles in Europe will have a market value of €250billion. That is why Daimler is investing heavily – more than €1 billion – in expanding its worldwide manufacturing network. The network will eventually consist of nine battery plants located in seven sites throughout Europe, North America, and Asia.

Daimler’s well-defined development objective is to increase the energy density of future batteries to significantly increase their range. Additionally, it aims to drastically cut charging times, hasten the serial maturity of future battery technologies, and further minimize crucial material consumption. For example, the cobalt concentration of future generations of battery cells will already be less than 10%. The goal is to eliminate the need for elements such as cobalt entirely through the use of post-lithium-ion technologies and novel material compositions. Further optimizing and implementing recyclability is also a component of the company’s comprehensive battery strategy.

Mercedes-Benz is preparing to switch to all-electric vehicles by the end of the decade if market conditions permit. By transitioning from electric-first to electric-only mode, the corporation is expediting its transition to a zero-emission, software-driven future. Mercedes-Benz is actively involved in the research and development of innovative recycling methods for vehicle batteries, as well as their market introduction. The goal of these endeavors is to mine today’s batteries for tomorrow’s batteries.

Additionally, the company is considering and planning the development of a battery recycling facility in Kuppenheim, Germany, to establish and secure recycling capacity and knowledge. The company plans to begin operations in 2023, pending the conclusion of positive conversations with governmental authorities.

To make electrification more appealing to buyers in the premium market, ambitious targets have been set: the development target for the EQS luxury car, which will be supplied to consumers next year, is a long-distance range of more than 700 km (WLTP range) and a charging speed that is double that of current models. Mercedes-Benz EQS models will also include CATL cell modules.

Additionally, Mercedes-Benz and Shell are collaborating to extend the charging network. Customers will benefit from expanded access to Shell’s Recharge network, which will include over 30.000 charge stations in Europe, China, and North America by 2025 – including over 10.000 high-power chargers. Mercedes-Benz is also aiming to open numerous premium-charging locations around Europe, each of which will provide a customized charging experience with top-of-the-line amenities. (Source)(Source)(Source)(Source)

“We intend to lead in battery technologies, so we are now combining our own research and development expertise with bold partners. We will integrate cutting-edge battery systems to create luxury cars with outstanding range, charging speed, safety, and sustainability. Working with CATL will see us accelerate our transformation towards carbon neutrality. CATL will be a major supplier securing capacity for the next generations of our EQ products in the years to come.”

Markus Schäfer, Member of the Board of Management of Daimler AG and Mercedes-Benz AG

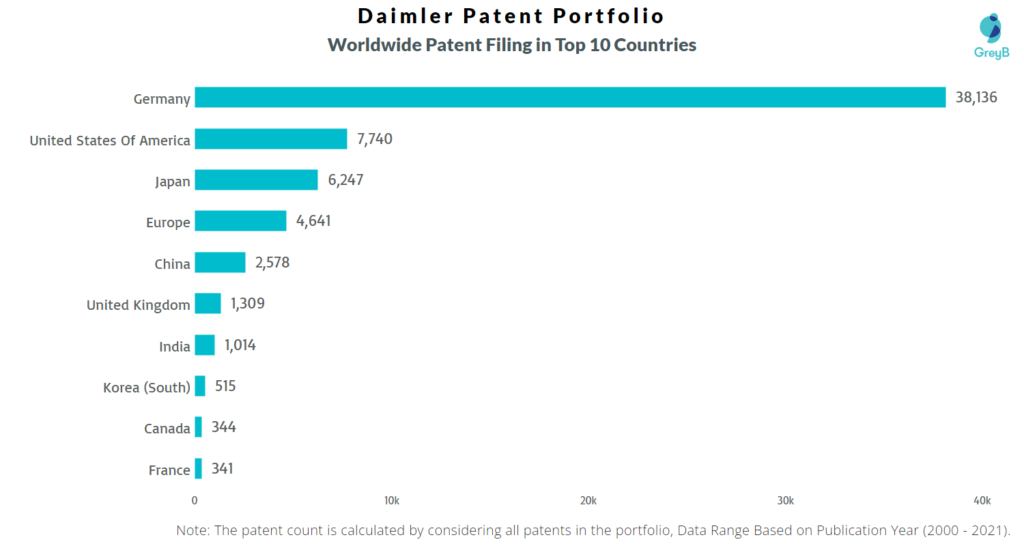

Patent Insights

Daimler has a total of 70121 patents globally. Germany is where Daimler has filed the maximum number of patents, followed by the United States Of America and Japan. The following are their primary technical interests: (Source)

Patent Filing Trend

Patent Filing in Different Countries

10. SAIC Motors

SAIC Motors, based in Shanghai, China, is a Chinese state-owned global automobile design and manufacturing corporation. In 2007, through its premium brand Roewe, the business debuted its first electric vehicle. (Source)

New Inventions/Technologies

Silicon-Doped Lithium Supplement Battery Cell Technology – SAIC Motor’s premium BEV brand, Zhiji Motor, stated in 2020 that it is collaborating with CATL. This collaboration aims the development of silicon-doped lithium supplement battery cell technology, which is intended to provide electric cars a range of up to 1,000 km (EVs). The year-to-be-launched batteries will have a 30% to 40% larger energy capacity than the current industry-leading level. (Source)

“Given the cost-related factor, the EV model with 1,000-km range is set to hit the market over the next five years.”

– Liu Tao, Deputy Head of Zhiji Auto’s Preparatory Team.

Mini Battery Swap Station – In 2021, SAIC, GM, and Liuzhou Wuling Motors to launch its smart compact battery swap station for new energy vehicles. The battery exchange station takes up the space required for two Baojun E200s to park. It can move around freely and does not require a vehicle to be parked properly; instead, it uses visual recognition and laser positioning technologies to detect it.

A single battery replacement takes about the same amount of time as filling up a gas tank, and the experience is identical to filling up a traditional automobile. It is one-third the cost of constructing a traditional battery switch station, and it can be enlarged like a building block. (Source)

Solid-State Lithium-Ion Battery – In 2021, SAIC said that it would release a solid-state lithium-ion battery with exceptional safety and energy density that will be commercially available by 2025. It’s unclear if SAIC will build its solid-state battery alone or in collaboration with a partner. (Source)

New-Generation Power Battery System – SAIC said in 2021 that their new-generation power battery system would be placed into volume production by the end of the year and that it would be used in the company’s newest premium vehicle, the R Auto. The all-new power battery system will handle solid-state battery technologies and lithium iron phosphate, ternary-lithium, high-nickel, and lithium-doped silicon batteries.

Its energy capacity can meet the power requirements of various models, from entry-level to large-scale luxury. Furthermore, the fresh power battery system is rated at 79% energy conversion with an energy density of 194Wh/kg. A 5-minute charge may give you a driving range of 135 km. (Source)

iSmart 2.0 Technology – The MG ZS EV has cutting-edge iSmart 2.0 technology. It integrates hardware, software, communication, services, and apps to make driving safer, smoother, and more intelligent. While charging the EV, the i-Smart EV 2.0 keeps the user informed on the charging current, voltage, and the remaining charging time.

It provides statistics on the amount of CO2 saved by driving the MG ZS EV and assists in determining the dynamic range 360 degrees from the present position depending on traffic and road conditions. On the included maps, users can now search for nearby charging stations and relevant information. Aside from the inbuilt SIM, the i-Smart EV 2.0 also offers the option of connecting the car to the internet through an external Wi-Fi network. (Source)

Focus Tech Area

SAIC Motor declared its aspirations to lead the industry in next-generation automobile battery systems, autonomous driving, and software technologies in 2021. Battery technology, autonomous driving, software technology, software-defined cars, and mechanism reform were among the aims it set for its enterprises.

MG Motors collaborated with Exicom Tele-Systems to make ZS EV batteries more reusable. Exicom, which uses SAP to store and manage data, uses the MG ZS EV batteries in a controlled process of evaluation, disassembly, and repackaging to create unique battery packs for non-automotive applications as part of the partnership.

SAIC Motor’s new energy vehicle development plan includes encouraging mass production of plug-in hybrid and electric vehicles and encouraging the creation of industrial applications and engineering testing on a larger scale.

SAIC Motor’s new energy vehicle development idea includes its plans to grow its research and development staff by using its core technologies and industrial production network. In core domains linked to new energy vehicles, the group will build more competitive R&D resources and a supply chain system and promote a service system that emphasizes ease of use, resource sharing, and green circulation. The company will soon be at the forefront of China’s new energy vehicle sector, developing technologically sophisticated cars and developing creative and comprehensive solutions for new energy vehicle customers.

SAIC Motor’s primary new energy vehicle efforts include a focus on industrial strategies and a commitment to the pure electric vehicle market, a focus on self-owned brands and plug-in hybrid electric vehicle adoption, and collaborating with joint ventures to speed up the market introduction of new energy vehicles. (Source)(Source)

Patent Insights

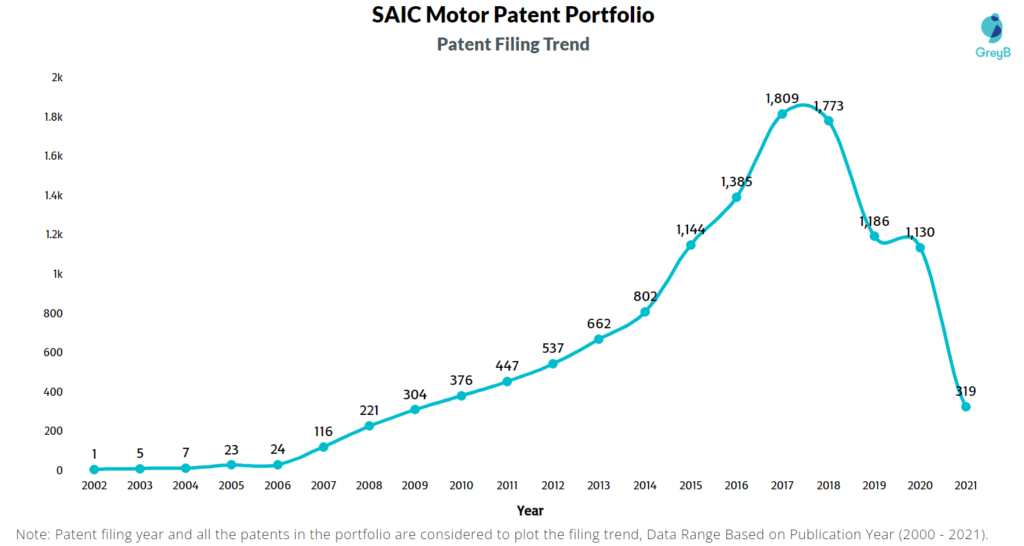

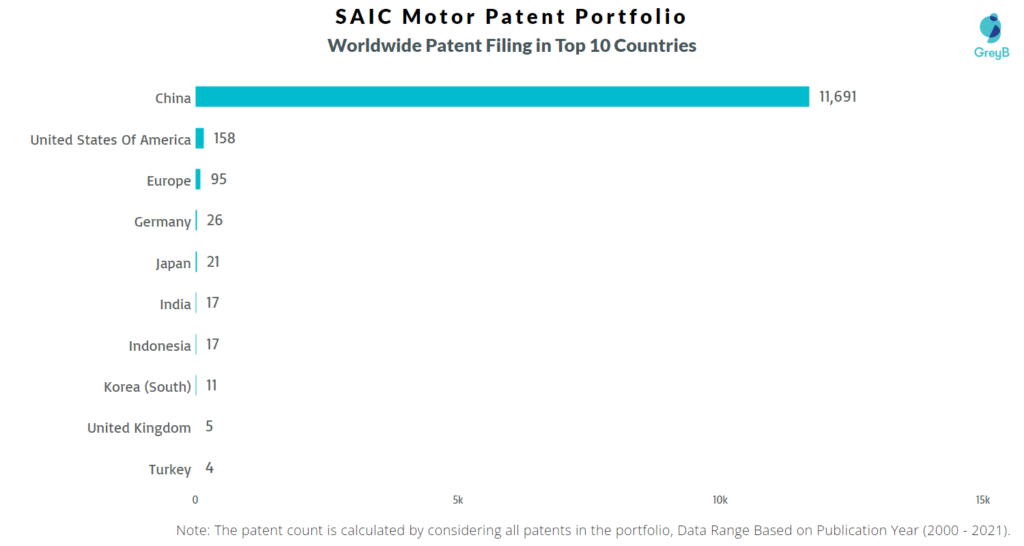

SAIC Motors holds a total of 12,271 patents worldwide. SAIC Motors has filed the most patents in China, followed by the United States and Europe, with China appearing to be SAIC’s primary R&D emphasis. (Source)

Patent Filing Trend

SAIC Patent Filings in Different Countries

Conclusion

For now, these top electric vehicle companies have been leading the global EV market with the most number of vehicle sales. The EV game has just started as EVs only have 5% of the market share compared to combustion engine vehicles. So, there is plenty of opportunity for prominent automotive companies like Ford, Volvo, Toyota, and Honda that haven’t got a place in the top 10 positions.

Moreover, EV is not just a battle between companies but the countries too. And like every trending technology, China is leading the EV market too. This might be a big concern for countries like the US, where EV sales are lower than China.

Not just the US, big market like India also understands the potential of EVs, and that’s why the Indian government, like the Chinese, are providing subsidy for buying new EVs. The local Indian player TATA Motors, the owner of Jaguar Land-Rover, is already working on EVs, and the prospect seems good for them.

Authored By: Vipin Singh, Market Research.

Next Read: Top 9 Electric Vehicle StartUps Innovating the Industry