Cell and gene therapies have moved decisively beyond their early experimental phase. As of 2025, over 250 gene-editing clinical trials are actively enrolling patients worldwide, with more than 150 trials using CRISPR-based platforms alone.

The field’s maturation is visible in recent regulatory milestones.

Casgevy, the first CRISPR-based medicine, received FDA approval in late 2023 for the treatment of sickle cell disease and beta-thalassemia. By mid-2025, 50 active treatment sites across North America, Europe, and the Middle East were administering the therapy.

More remarkably, in 2025, physicians at Innovative Genomics Institute delivered the first personalized, on-demand in vivo CRISPR treatment to an infant with a rare genetic disease—accomplishing design, regulatory clearance, and administration in just six months.

This case established a critical precedent. The FDA agreed that once initial toxicology studies qualify a lipid nanoparticle delivery platform, subsequent therapies targeting different genetic variants would not require new animal studies. Instead, in vitro testing in engineered human cells suffices.

This regulatory flexibility dramatically reduces timelines and costs, making personalized gene therapies feasible for small patient populations.

Despite such tremendous progress, the cell-based therapy still faces several challenges, such as manufacturing, scalability, quality control, cell viability, etc.

This article discusses the technical challenges in cell-based therapies and how the industry is addressing them.

Major Challenges in Cell-Based Therapy and Their Solutions

1. Manufacturing Complexity and Scalability

CAR T-cell therapies face significant manufacturing hurdles that limit their widespread adoption. Since T cells are biologically complex living materials requiring precise culture conditions and expensive growth factors. As a result, they are difficult to manufacture at clinically relevant quantities, requiring sophisticated facilities to isolate, modify, expand, and process cells.

The current production processes are laborious, time-intensive, and expensive, with costs reaching prohibitive levels for many patients.

ImmunoACT has revolutionized CAR-T manufacturing economics through an innovative approach that dramatically reduces production costs. Their NexCAR19 therapy costs between $30,000-$40,000 per treatment, compared to the $370,000-$530,000 charged by Western competitors.

ImmunoACT achieved this breakthrough by manufacturing all components in-house, including the CAR vector, T cell growth media, and other critical reagents. They deliberately avoided expensive automated production machinery used by Western companies, instead optimizing a semi-automated process tailored for high-volume production.

Their manufacturing platform achieves a production cost of approximately $16,000 per patient when operating at 400 patients per year, demonstrating scalability suitable for low and middle-income countries. The company maintains a 100% manufacturing success rate while eliminating the need for ICU admissions for the management of cytokine release syndrome.

Cell Therapy Startups

2. Quality Control and Cell Viability

Assessing and optimizing cellular quality during automated cell engineering presents substantial challenges. Monitoring molecular characteristics across manufacturing is challenging, yet essential for maintaining therapeutic efficacy.

Cell viability, phenotype consistency, and functional properties must be carefully controlled, as variations can significantly impact treatment outcomes. The lack of standardized quality control across different manufacturing platforms leads to inconsistencies in final cell products.

Cellares addressed the downstream QC bottleneck by creating Cell Q, the world’s first automated quality-control workcell for cell therapy manufacturing. Launched in April 2024, Cell Q addresses the manual, labor-intensive, low-throughput nature of cell therapy quality control testing.

The system automates the vast majority of cell therapy QC assays for up to 6,000 batches per year, delivering substantial improvements in throughput, cost, and reproducibility compared to manual QC methods.

Cell Q includes a pre-qualified set of the most common assays to accelerate analytical method transfer and shorten time to clinical readout for new clients. The modular platform design allows expansion with new instruments, providing flexibility to meet varying client needs for both in-process and release testing.

By combining Cell Shuttles for upstream manufacturing with Cell Q for downstream QC, Cellares has created an end-to-end solution that addresses the entire manufacturing and testing workflow.

3. Toxicity Management

Cytokine release syndrome (CRS) and immune effector cell-associated neurotoxicity syndrome (ICANS) remain major safety concerns. These systemic inflammatory responses, triggered by cytokine release from engineered cells, can range from mild to life-threatening.

Research reveals that predicting which patients will experience severe toxicity remains challenging, with pre-treatment biomarkers like IL-15 and MCP-1 levels showing promise but requiring further validation. Managing on-target/off-tumor toxicity and prolonged cytopenias continues to complicate treatment protocols.

Nature Medicine researchers developed InflaMix, an innovative inflammatory biomarker signature that predicts CAR-T treatment response and toxicity risk before infusion. Using a cohort of 149 patients with non-Hodgkin lymphoma, the InflaMix model analyzes 14 laboratory features, including unconventional cytokines (IL-6, TNF, IL-10,) to identify patients at high risk of treatment failure.

The predictive model demonstrates a 9% improvement in area under the receiver operating characteristic curve (0.73 versus 0.64) compared to regularized models using all 14 laboratory features individually.

InflaMix-informed prediction of progression-free survival at 6 months significantly outperforms both CRP-based models and baseline clinical factors (AUROC: InflaMix 0.74, CRP 0.67, Base 0.68).

The biomarker signature provides better risk calibration and greater net benefit for clinical decision-making across all relevant threshold probabilities. This precision-medicine tool enables clinicians to stratify patients before CAR-T infusion, enabling preemptive management strategies for high-risk individuals.

Gene-Based Therapy Startups for Neurological Disorders

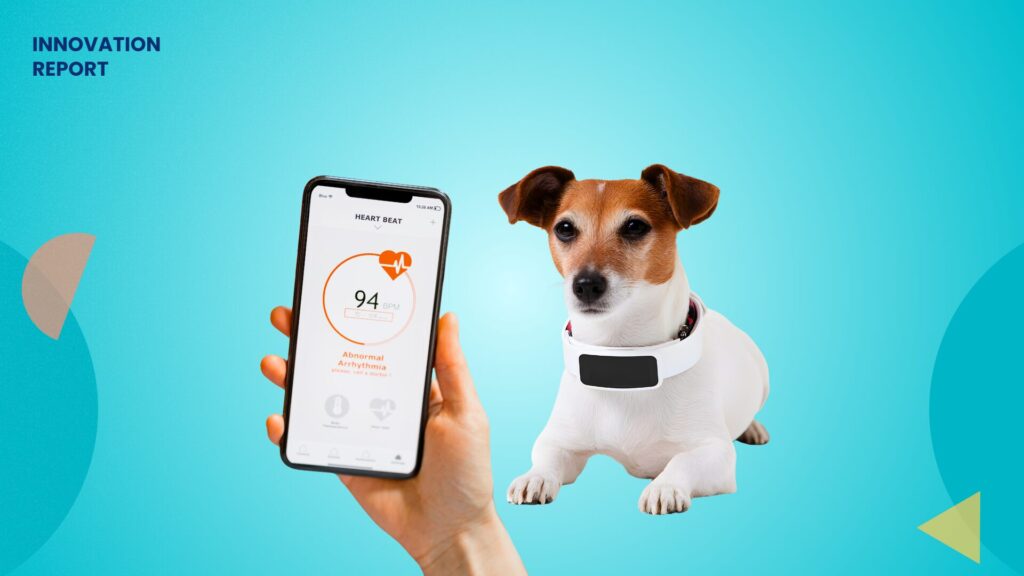

4. Patient Variability and Response Prediction

Individual patient characteristics significantly influence therapy outcomes. However, predicting responses is still tricky. Tumor burden, blood analytes, and disease-specific factors create substantial variability in treatment efficacy.

A key hurdle is predicting which patients will respond to cell therapy and which are likely to experience harmful side effects. The heterogeneity in patient immune status, prior treatments, and disease progression complicates the adoption of standardized treatment approaches.

Atara wants to fix this by custom-making the therapy from each patient’s own cells. Their approach is an “off-the-shelf” version built from healthy donor cells, so it’s ready when needed and more consistent.

The lead program, ATA3219, uses donor T cells that are already trained against the common EBV virus and then upgraded with a CD19-targeting CAR; it’s a modern “second-gen” design with a 1XX co-stimulatory switch to help the cells activate reliably without burning out.

Its EBV T-cell platform provides several crucial advantages. Cells are derived from donors with healthy immune function, allowing rapid delivery from inventory without patient-specific manufacturing delays.

The clonally expanded EBV T cells inherently possess lower potential for alloreactivity, addressing the key safety concern of allogeneic therapies causing graft-versus-host disease.

The 1XX signaling domain optimizes T-cell expansion and mitigates exhaustion, while the memory phenotype enhances long-term persistence. Atara has invested $55 million in a 90,000-square-foot CAR-T manufacturing facility in Thousand Oaks, California, designed specifically for large-scale allogeneic production.

Their preclinical studies demonstrate that EBV.CD19.CAR T cells effectively eliminate in vitro alloreactivity and significantly inhibit tumor growth in aggressive lymphoma mouse models after a single injection. Atara is currently investigating ATA3219 for CD19+ relapsed or refractory B-cell malignancies and B-cell mediated autoimmune diseases, including systemic lupus erythematosus with kidney involvement.

5. Technical and Logistical Barriers

The ex vivo engineering process involves multiple complex steps requiring specialized facilities and expertise. Achieving adequate cell expansion while maintaining desired phenotypes presents technical difficulties.

Coordinating manufacturing timelines with patient treatment schedules creates logistical challenges, particularly when initial cell expansions fail quality criteria and require rescheduling. The need for patient-specific autologous therapies further complicates large-scale production and distribution.

Thermo Fisher’s development of 24-hour autologous CAR-T manufacturing processes makes point-of-care production feasible by dramatically compressing timelines. The advanced, automated, closed, lentivirus-based method requires fewer manual touchpoints, improving process consistency across decentralized sites.

Automated cell therapy platforms provide manufacturers and providers more agility, enabling them to quickly restart production if initial batches fail quality criteria, limiting negative impacts on end-to-end lead time and patient experience.

The integration of instruments with digital automation and increased operational modularity facilitates the standardization required for successful decentralized manufacturing networks.

Conclusion

Cell-based therapy is shifting from custom research projects to standardized, scalable production systems.

Success now depends on three things: speed, cost control, and safety—all driven by choosing the right partners, technology platforms, and data strategies.

Leading companies aren’t chasing single breakthroughs anymore.

Instead, they’re building integrated systems that include modular manufacturing setups, real-time quality control, strong supplier networks, and robust data infrastructure.

These systems help them get therapies into clinical trials faster while reducing the risks associated with scaling up production.

If you’re facing challenges like cost of goods, choosing between point-of-care and centralized manufacturing, using biomarkers for safety monitoring, or selecting the right partners, there’s a way to cut through the noise.

Mapping out your options, evaluating the trade-offs, and identifying relevant vendors and technologies that fit your needs can clarify the path forward.

Share a brief overview of your specific challenge with us, and we’ll show you the right path to success.

How Can We Help You?

We support industry-leading R&D and Innovation professionals through complex problems. Describe your challenge, and let us bring clarity and expertise.