Process heating accounts for nearly half of the total energy used in industries, but it’s often inefficient. About 20-50% of this energy is lost as waste heat. This not only wastes fuel but also leads to higher costs and increased carbon emissions.

To address this issue, a startup named Efenco provides a plasma-enhancing technology that can be integrated into existing combustion systems. Their technology reportedly boosts energy conversion efficiency by at least 18%, reducing fuel consumption and CO2 emissions without requiring major modifications or external power sources.

To better understand Efenco’s plasma generation technology, we spoke to Kristjan Tiik, CEO. This article contains notable highlights from our conversation.

This interview is part of our exclusive Scouted By GreyB series. Here, we speak with the founders of innovative startups to understand how their solutions address critical industry challenges and help ensure compliance with industry and government regulations. (Know more about startups scouted by GreyB!)

“We found a way to create plasma using waste heat from combustion, which opens up entirely new applications previously unavailable.”

– Kristjan Tiik

Kristjan Tiik is the CEO and Co-founder of Efenco, a deep-tech company focused on innovative energy solutions. He has over 25 years of experience in innovation and business management. Before founding Efenco, Kristjan played key roles in transforming businesses like AS Piletilevi, a leading online ticketing platform in the Baltics, and advised over 200 startups at Enterprise Estonia. At Efenco, Kristjan leads the development of groundbreaking technologies, such as HERC (High Energy Ray Ceramic), which enhances combustion efficiency and reduces greenhouse gas emissions.

How Efenco Uses Waste Heat to Enhance Industrial Heating Systems

Efenco is a deep-tech startup working to enhance energy efficiency in industrial heating systems. Their core innovation lies in utilizing plasma to improve combustion processes. By integrating existing boilers with their unique tiles, Efenco helps industries reduce fuel consumption and lower CO2 emissions. Their system operates without requiring any external power source or substantial modifications to existing infrastructure, making it a game-changer for industrial heating applications.

Could you elaborate on the specific functions of Efenco’s technology and how it operates?

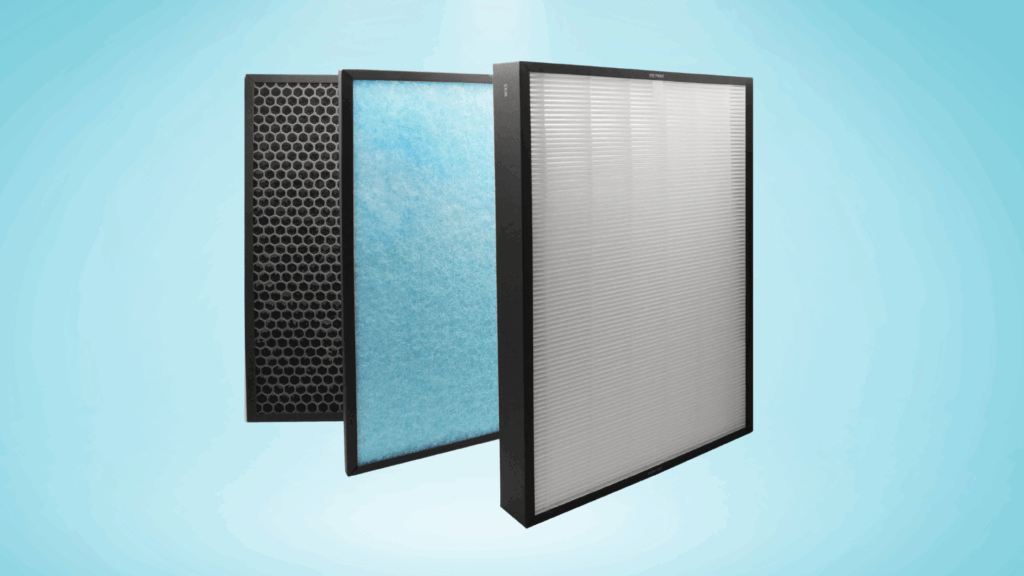

Kristjan: Efenco’s technology focuses on enhancing the combustion process by using plasma. In most industrial boilers, combustion is the primary method of generating heat; however, it is often an inefficient process. We have developed tiles that can be easily integrated into existing systems. These tiles utilize the heat from combustion to generate photons, which in turn initiate plasma reactions that enhance the efficiency of the combustion process. This means you can reduce fuel consumption and lower CO2 emissions without making significant changes to your current setup.

What differentiates your solution from others available in the market?

Kristjan: The key difference is that our system doesn’t require any external power or system modifications. Plasma technology has been around for some time. Still, the issue with traditional methods is that they need additional energy to generate plasma, which makes them less viable for large-scale industrial applications. Our system, however, creates plasma using the waste heat that is already being produced, thereby enhancing efficiency without requiring additional energy. It’s a straightforward solution that can be easily integrated into existing systems.

Can you share some of the biggest challenges you faced while developing this technology?

Kristjan: One of the biggest challenges was making sure our technology worked across the wide range of industrial systems out there. Boilers operate at different temperatures, sometimes reaching up to 1000 degrees Celsius, so we had to ensure our tiles could handle those extreme conditions. Additionally, we needed to strike a balance between performance and longevity, given that we are working with ceramic materials. However, through trial and error, we have developed a reliable system that performs effectively in real-world settings.

Does your technology work with all types of fuels, such as methane or biogas, or is it specifically designed for one type?

Kristjan: The great thing about our technology is that it’s designed to work with a variety of gases, including methane and hydrogen, which are commonly used in industrial applications. We’ve tested it with different fuels, and the plasma-enhanced combustion process works just as effectively across the board. That said, solid fuels may present some additional engineering challenges, but we plan to explore this further down the line. The core principle behind it remains the same: harnessing waste heat to increase combustion efficiency.

What are the future prospects for Efenco? How do you envision the company evolving over the next few years?

Kristjan: Over the next few years, we will focus on completing the final stages of product development and rolling out our technology in more industrial settings. We also plan to expand our team to tackle new challenges and explore even more applications for our technology. Our long-term goal is to transform the way industries utilize energy by offering a straightforward, scalable solution that enhances efficiency and minimizes environmental impact. We’re excited about the potential and confident that Efenco can make a meaningful difference in the clean energy space.

What are your thoughts on the long-term environmental impact of your technology?

Kristjan: The potential environmental impact is significant. By improving the efficiency of combustion processes, we’re helping industries use less fuel to generate the same amount of heat. This leads to a reduction in both fuel consumption and CO2 emissions. Given the energy-intensive nature of industrial processes, this can make a significant difference, not only for the companies using our technology but also for the environment as a whole. If we can scale this approach across various industries, we could significantly help reduce global carbon emissions.

What challenges do you anticipate as you work to expand this technology and introduce it to additional industries?

Kristjan: A significant part of scaling our technology is ensuring it meets all regulatory requirements and industry standards. While our system is based on fundamental physics, we will need to collaborate with regulators to ensure it is compliant with industry standards. We’re also focused on working with customers to make sure that the technology is adopted smoothly. As we grow, we anticipate encountering some hurdles, but we are confident that the benefits will help us overcome any challenges.

As we look ahead, how do you envision the development and expansion of Efenco, along with its technological advancements?

Kristjan: We’re aiming to expand the applications of our technology beyond just industrial heating. One area that excites us is scaling it for use in smaller applications, such as internal combustion engines. We’re even discussing with manufacturers in the aviation industry the potential application of our technology to jet engines. As we move forward, we are focused on expanding the technology’s reach and ensuring its accessibility to industries worldwide. We believe Efenco has the potential to be a key player in improving energy efficiency and reducing emissions on a global scale.

Meet our Interviewer – Shabaz Khan, Marketing Manager at GreyB

Shabaz Khan, Marketing Manager

Want to find other scalable startups innovating in industrial energy efficiency and carbon reduction technologies? Please fill out the form below to contact our experts.

Get in touch

Please share your query below