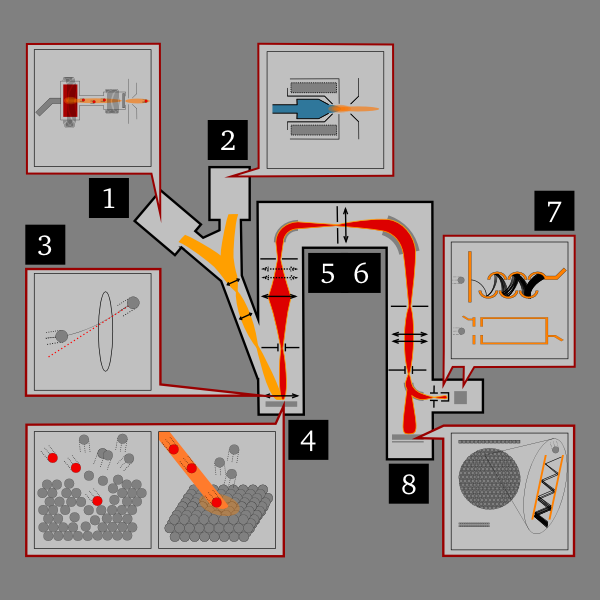

Dynamic SIMS

- Dynamic Secondary Ion Mass Spectrometry instruments capable of parts-per-billion sensitivity for depth profiling analysis.

- Has high mass resolution capability, and often used for P doped samples in SI wafers (MR > 4000).

- Depth profiling can be optimized for low energy ultra-shallow implants or for several micron deep layers

Specifications

- Dual source (O & Cs)

- Sensitivity: ppm-ppb

- Depth resolution < 1nm

- Detect all elements with isotope information

- Sputter energy: O 2+: 1-10kv, Cs+: 1-15kv

- Best mass resolution > 25400

Applications

- Depth profiling

- Thin film composition: Ntrided gate oxide and SiGe

- Contamination analysis and control in oxide/active/well

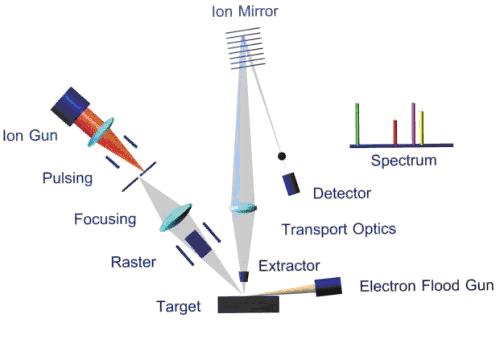

TOF SIMS

- Time-of-flight Secondary Ion Mass Spectrometry is a versatile instrument capable of parts-per-million sensitivity or better with parallel detection for nearly all elements and molecules up to several thousand atomic mass units.

- Mass resolved imaging provides mapping with lateral resolution better than 150nm.

- Surface analysis sensitivity is comparable to TXRF, though it also provides lower mass range sensitivity and targeting of smaller areas.

- Depth profiling with sputter ion guns can be optimized for low energy ultra-shallow implants or for several micron deep layers.

Specifications

- Mass range: 0-10,000 amu

- High mass resolution: M/ΔM over 10000

- Sensitivity: ppm-ppb

- Detected element: H – U (Isotope)

- Depth resolution: <1 nm

- Lateral resolution: 0.1-1 µm

- Sputter gun: O2+: 0.25-2kv, Cs+: 0.25-2kv

- Analysis gun: Bi+, 25kv

Applications

- Surface analysis of organic and inorganic materials

- Elemental and molecular information about surface, thin layer, interfaces of material and surface contamination

- Positive & negative ion mass spectra and 2-D ion mass spectral image information

- 3-D ion image analysis

- Depth profile analysis

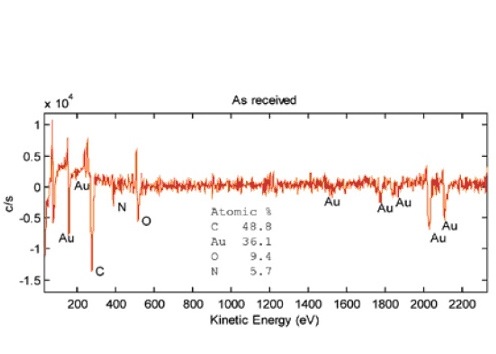

XPS (X-ray Photoelectron Spectroscopy)

- X-ray Photoelectron Spectroscopy is qualitative surface analysis technique that can characterize the surface chemistry of materials (chemical state and concentration).

- X-rays are focused onto material, and then measure the emitted electrons intensity and energy from the top 1-10nm of the surface.

- Quantified elemental depth profiling through layers can provide both layer and contamination intensities.

Specifications

- Beam size: 7.5-200 um

- Lateral resolution: 10 µm

- Depth resolution: 1.0 nm

- Energy resolution: 0.48 eV

- Detected element: Li – U

- Sensitivity: 0.1-1.0 at%

Applications

- Surface analysis of inorganic and organic materials, contamination, stains or residues

- Quantification of surface elemental composition

- Determination of chemical state/bonding information

- Depth profiling for thin film/material composition

- Film/material and oxide thickness measurement

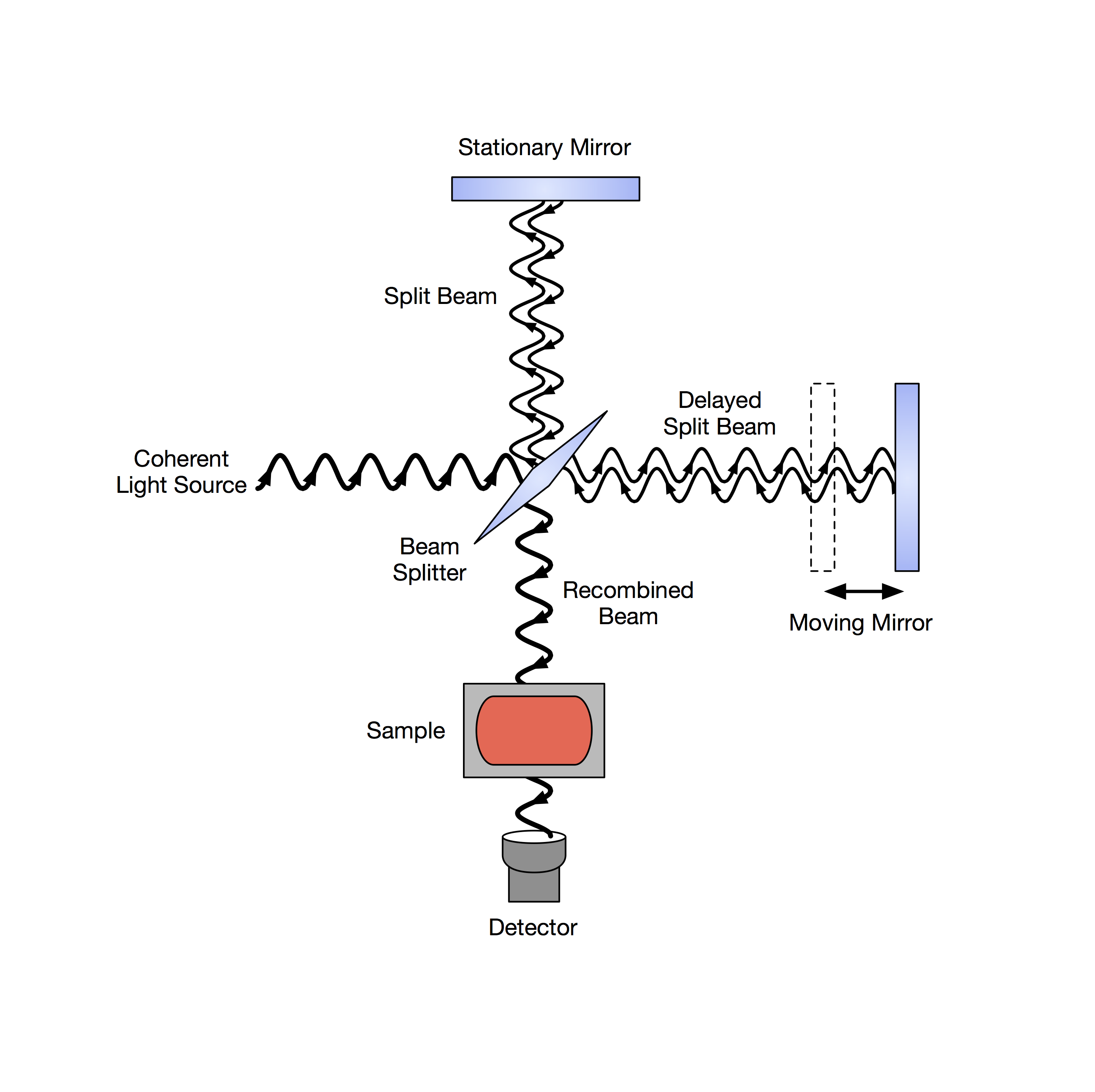

FTIR (Fourier Transform Infrared Spectroscopy)

- Fourier Transform Infrared Spectroscopy (FTIR) is commonly used to extract specific information about chemical bonding and molecular structures. It is particularly powerful tool for analyzing organic materials.

- An infrared spectrum represents a fingerprint of a sample with absorption peaks that correspond to the frequencies of vibrations between the bonds of the atoms making up the material. Because each different material is a unique combination of atoms, no two compound produce the exact same Infrared spectrum.

Specifications

- Mid- to Far-IR: 5000-80 cm-1

- Penetration depth: ~1-2 µm

- Sample size: >25 µm

- Full Commercial Spectra Library

Applications

- Identification of all types of organic compounds(solid and liquid) and organic functional groups (chemical bonds)

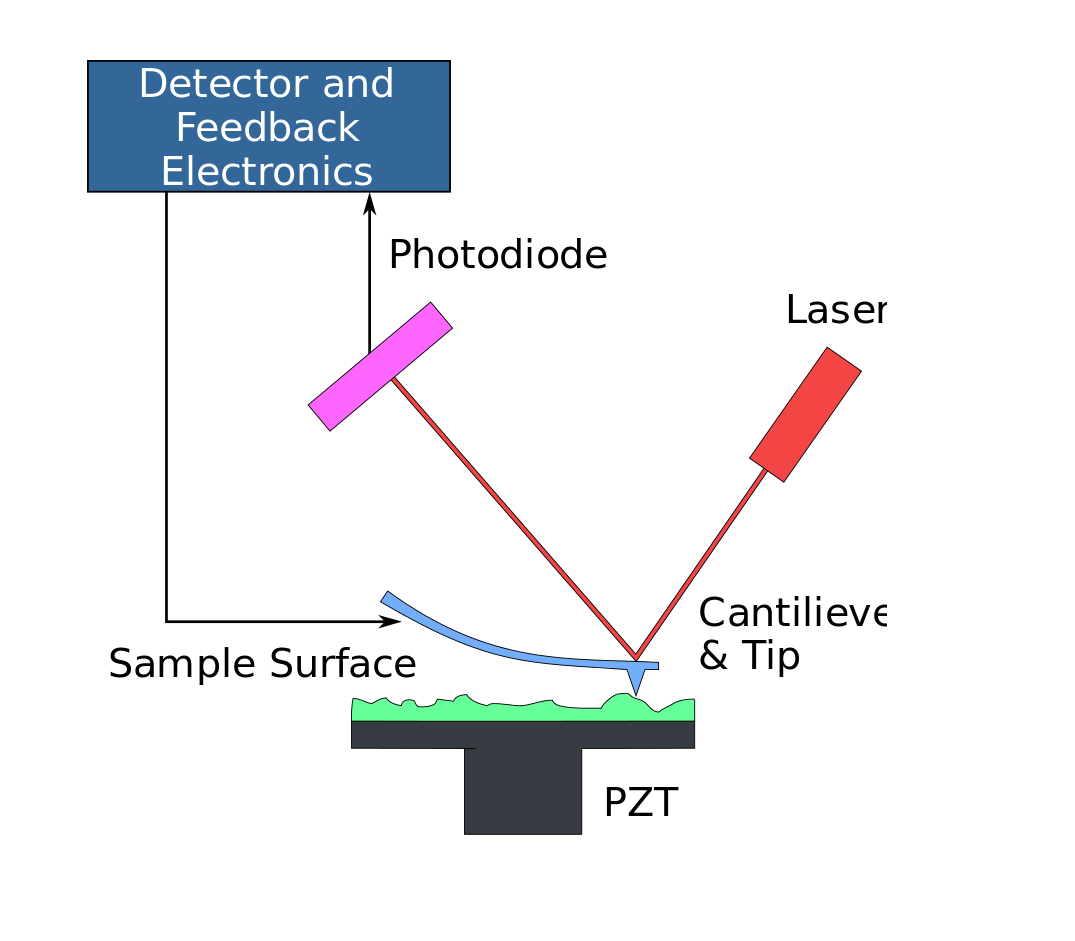

AFM (Atomic Force Microscope)

- Atomic Force Microscope (AFM) measures atomic surface topography, which is ideal for characterizing surface roughness at an angstrom scale.

- Besides surface roughness, AFM can provide quantitative measurements of grain size, step height by 3D surface topographic imaging, and capacitance, phase, magnetic field by pitch imaging.

Specifications

- Vertical resolution ~0.1nm

- Best lateral resolution ~7nm

- Maximum scan area 80um x 80 um

- Current range in C-AFM 10pA – 10uA

- Force range in Nanoindentation 1-100uN

Applications

- Surface topology mapping

- Surface roughness measurement

- Electrical current mapping by Conductive Module

- Hardness and Modulus by Nanoindentation Module

EBSD

- Electron backscatter diffraction (EBSD) is a microstructural-crystallographic characterisation technique to study any crystalline or polycrystalline material. The technique involves understanding the structure, crystal orientation and phase of materials in the Scanning Electron Microscope (SEM).

Specifications

- Attached to Helios 600i

- Lateral resolution ~80nm

- Angle resolution ~0.3°

Applications

- Preferred orientation

- Special grain boundary (twin boundary, large angle and small angle boundaries)

- Grain size distribution

AES (Auger Electron Spectroscopy)

- Auger Electron Spectroscopy is a near surface (<5nm) instrument capable of quantifying many elements from a fraction of 1 atomic percent up to 100 percent. It also has better lateral resolution (<10nm) than TOF SIMS, and better surface sensitivity than EDX.

- Elemental Auger mapping is very flexible, and it excels in identifying the composition of small defects and residues.

- Quantified depth profiling through layers can provide both layer composition and interfacial contamination levels.

Specifications

- FEG tip (3-25kV), small sample stage

- CMA detector (all elements except H & He)

- Detection limit: 0.1 to 1.0 atomic %

- SEM: 7nm@20kV; SAM: 10nm@20kV

Applications

- Small size defects down to 20-30nm

- Depth profiling to characterize the contamination

- Element mapping of nano defects

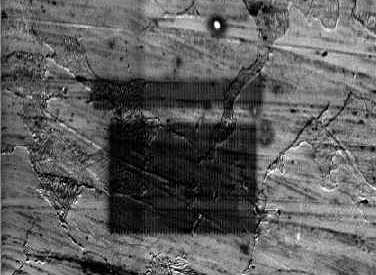

Dual Beam FIB (Focused Ion Beam)

- Focused Ion Beam (FIB) is a versatile analysis technique that can be used to expose hidden defects in a variety of substrates.

- A common application is to prepare samples for TEM analysis using the lift-out technique.

- Another application of FIB is in circuit editing. Electrical connections can be cut and re-routed within the FIB system.

Specifications

- Ga liguid metal ion source, Ga LMIS

- Resolution 5nm at 30kV

- Accelerating voltage 0.5 – 30kV

- Beam current 1.5 pA – 20 nA

- EDX system Oxford Instruments

- EBSD system Oxford Instruments

Applications

- Electro and Ion Beam Imaging

- Micro and Nano Patterning

- Site Specific Cross-sectioning

- Site Specific Deposition

- IC Circuit Editing

- 3D Progressive Milling

- 3D L-Shape Milling

- TEM Sample Preparation

Ion Beam Milling

Specifications

- Argon Ion Beam: 100eV to 6.0 keV

- Cut Width: 0.5 – 5 mm

- Sample Size: 10 X 10 X 4 mm3

- Minimum Sample Temperature: -150°C

Applications

- Large Area Milling & Observation

- Preparation for SEM/EBSD/CAFM

- Delamination and porous cross section

- Delayer

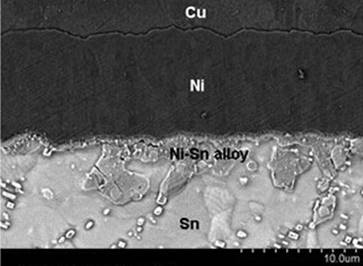

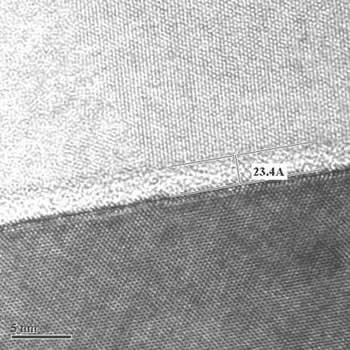

TEM (Transmission Electron Microscope)

- Transmission Electron Microscope (TEM) is a high resolution analysis technique that allows one to see detail on an atomic scale.

- Samples are generally prepared until they are thin enough for electrons to penetrate through it to the detector.

- Coupled with EDX or EELS, quantitative information can be obtained.

- Another application of TEM is to make metrology measurements of crystalline, amorphous, layers, etc.

Specifications

Electron source

- Flexible high tension (20, 40, 80, 120, 160, 200 kV and values in between)

- Schottky field emitter with high maximum beam current (> 100 nA)

- High probe current (0.5 nA or more in 1 nm probe)

Imaging

- TEM point resolution (0.24nm)

- Information limit (0.14nm)

- TEM magnification range 25X-1030kx

- Maximum diffraction angle STEM HAADF resolution (0.19nm)

- STEM magnification range Maximum tilt angle with double-tilt holder + 40°

- EDS solid angle 0.13 srad

- Sample size 10um*4um*100nm(thickness)

Applications

- TEM Imaging and Measurement

- HRTEM Imaging

- EDS Elemental Mapping

- Diffraction analysis and Phase Reconstruction

- Planar View (PV) + Cross Section (XS) TEM

- One Stop Solution

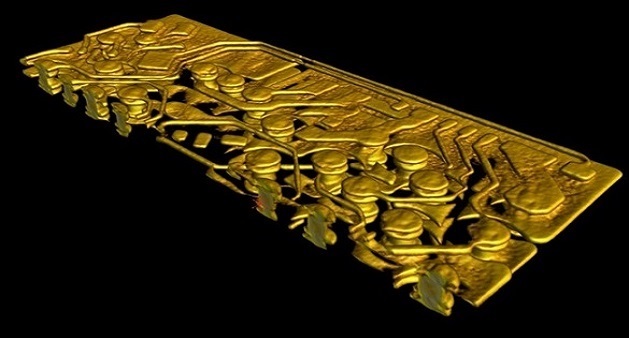

2D/3D X-ray (Industrial CT)

Specifications

- 0.5um recognition resolution

- High power penetration

Applications

- Non-destructive analysis through package

- Wire Bonding integrity

- Die attach delamination

C-SAM

Curve Trace

Specifications

- Reflection and Through scan mode

- 230MHz high frequency transducer

Applications

- Non-destructive analysis through package

- Package delamination

- Stack die delamination

Specifications

- 1pA to 100mA range

- 100uV to 100V range

Applications

- Electrical failure validation

- I-V, C-V

Micro Probing

Deprocessing

Specifications

- 5um prober

- Integrate with test board

Applications

- Electrical failure validation

- Circuit Edit

Specifications

- RIE delayer

- Mechanical delayer

- Chemical delayer

Applications

- Remove Passivation/Metal/Oxide

- Metal short/open

- TEM sample preparation

Chemical Etch

EMMI

Specifications

- Acid etch

- Bas etch

- Solvent

Applications

- Junction stain

- Si dislocation defect

- Epi contamination

Specifications

- InGaAs detector

- Lens 0.8x, 2.5x, 5x, 20x, 50x, 100x

- 12” wafer probe station

- Probe card integration

Applications

- ESD damage localization

- p-n junction leakage

- MOSFET short

- Latch-up localization

- Pressure resistance defect

- Wafer backside analysis

OBIRCH

Thermal

Specifications

- Dual laser 1300nm and 1064nm

- Lens 2.5x, 5x, 20x, 50x, 100x

- 12” wafer probe station

- Digital Lock In function

- Probe card integration

Applications

- Metal open short localization

- ESD damage localization

- p-n junction damage

- Latch-up localization

- Pressure resistance defect

- Wafer backside analysis

Specifications

- InSb detector

- Lens 0.8x, 4x, 8x, 15x

- 12” wafer probe station

- Probe card integration

Applications

- Replacing Liquid Crystal

- Special grain boundary (twin boundary, large

- angle and small angle boundaries)

- Grain size distribution