Samsung captured the spotlight by announcing its groundbreaking solid-state battery technology at the InterBattery conference held on November 5, 2023, in Seoul, South Korea. This next-generation battery is set to redefine the electric vehicle (EV) market, offering an unprecedented range of up to 965 kilometers on a single charge and the ability to recharge in just nine minutes.

These state-of-the-art solid-state batteries also have a life span of 20 years. Testing batches of these batteries have already been shipped to major automotive manufacturers.

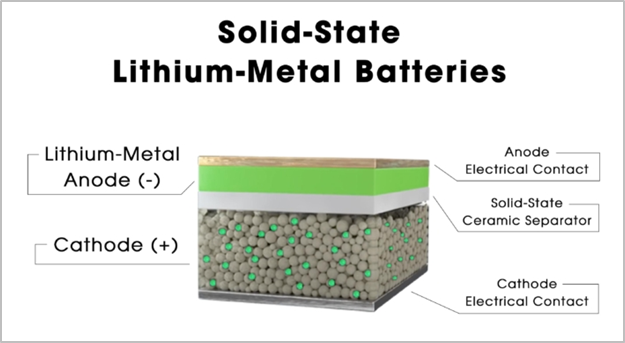

Solid-state batteries (SSBs) present a compelling alternative to traditional lithium-ion (Li-ion) batteries. SSBs offer advantages in terms of size, weight, safety, capacity, and recharging speed. Due to the absence of a liquid electrolyte, they can be smaller and lighter, making them ideal for applications including electric vehicles (EVs).

Additionally, SSBs boast faster charging times, with claims of reaching 80% charge in as little as 10-15 minutes, compared to Li-ion batteries, which can take longer. SSBs can also store energy density in each cell, typically between 300 Wh to 400 Wh, greater than traditional batteries. Moreover, SSBs offer greater energy density, enabling longer driving ranges on a single charge.

With their enhanced safety features, higher thermal stability, and potential for lower carbon footprints, SSBs represent a significant advancement in battery technology with the potential to revolutionize various industries. Properties like these attracted many EVs and energy storage systems (ESS) players to Solid State Batteries (SSB).

Despite all these advantages, SSBs still have some significant challenges to solve. For instance, the new Samsung batteries have high production costs and are expected to be available for high-end EVs for the initial phase.

We have discussed those challenges in detail later in this article. However, if companies (like yours) solve these issues, it would be a massive step for the EV and Energy Storage industries.

5 Trends are Impacting Energy Storage in 2025. Learn about them with our exclusive report:

Before we dive deep into the future of solid-state batteries, let’s talk about the advantages of SSB and the challenges companies need to overcome to unlock their full potential.

Advantages of Using Solid-State Battery

Greater safety

Solid-state batteries are much safer than Lithium-Ion batteries. This is because SSBs don’t have a liquid electrolyte, one of the most troublesome components in lithium-ion batteries, as it’s volatile and thus more combustible. Instead, SSBs are altered by a thicker separator layer of a material structurally more resistant to high temperatures. It improves the separation between the anode and cathode, preventing short circuits even on occasion of misuse or degradation, thus increasing the intrinsic safety of the cells.

Keeping track of energy density

Solid-state batteries possess an energy density of 2-2.5 times that of existing lithium-ion technology. This makes it a lighter and more compact battery. In addition, the increased inherent safety contributes to another significant improvement, i.e., using a pure metal anode promotes a substantial boost in energy density. The ions stay during the transfer in a solid-state battery, and a bulky, heavy chemical portion that does not actively help create energy is removed.

Ultra-fast charging times

Solid-state batteries can charge up to six times more quickly than existing technology on the market. Existing solid-state battery models charge very fast but at the expense of other critical performance parameters.

Challenges of Solid-State Battery

Presence of substitutes

Graphene batteries, fluoride batteries, sand batteries, ammonia-powered batteries, and lithium-sulfur batteries are replacements or substitutes for solid-state batteries. Fluoride batteries have the potential to run up to eight times longer than solid-state batteries. The new lithium-ion battery uses silicon instead of graphite to achieve three times the performance of the existing graphite Li-ion batteries. During the forecasted period, all of these batteries limit the expansion of the solid-state battery market.

Complicated manufacturing process

Solid-state battery production procedures and methods are complicated. During the creation of these batteries, suitable production tools are required for highly precise material deposition. Solid-state batteries are made by systematically arranging electrodes separated by solid electrolytes. These non-porous solid electrolytes must be able to prevent dendrite growth between electrodes. As a result, solid-state battery producers must constantly focus on research and development efforts linked to these batteries to analyze the difficulty of the production process of solid-state batteries.

Toyota's Research in Solid State Batteries

Solid-State Battery Companies

1. QuantumScape

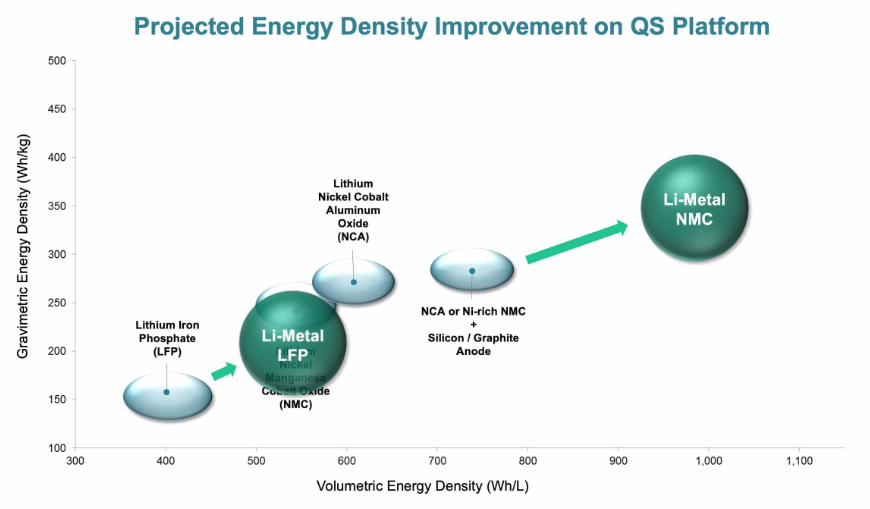

QuantumScape is working to commercialize solid-state batteries for use in electric vehicles. It aims to reduce manufacturing costs, making battery production more economical and accessible for widespread adoption. The company is also working on enhancing energy density through its solid-state lithium-metal battery technology.

Unlike traditional lithium-ion batteries, QuantumScape’s Solid-State Lithium-Metal Battery features an innovative anode-less design and a proprietary solid ceramic separator. The technology eliminates the need for graphite or silicon anode host material and replaces the organic separator with a solid ceramic one.

It is also developing a novel manufacturing process that will enable the mass production of these batteries at a lower cost than traditional lithium-ion batteries.

Volkswagen Group’s battery company PowerCo and QuantumScape have entered into a groundbreaking agreement to industrialize QuantumScape’s next-generation solid-state lithium-metal battery technology. This non-exclusive license allows PowerCo to produce up to 40 gigawatt-hours (GWh) annually using QuantumScape’s technology, with the option to expand to 80 GWh, potentially powering one million vehicles annually.

The partnership, which supersedes a previous joint venture, combines QuantumScape’s cutting-edge technology with PowerCo’s global industrialization expertise.

The company has also made agreements with two other major global automakers and is expanding its business to Asia-Pacific with an office in Kyoto, Japan. This new property will feature a state-of-the-art laboratory for battery research and development.

2. Cymbet Corporation

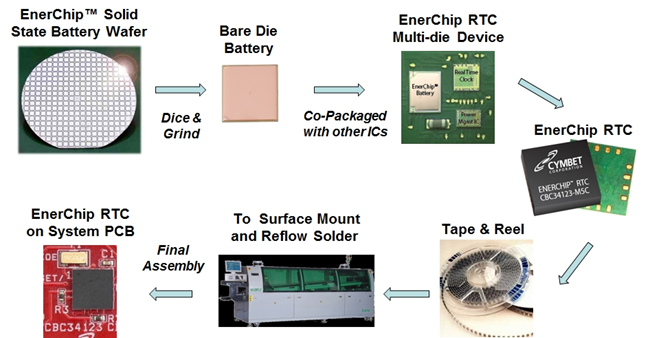

Cymbet Corporation, headquartered in the United States, is a leader in solid-state energy storage solutions for microelectronic systems. The company is the first to commercialize eco-friendly, biocompatible rechargeable solid-state batteries. This gives electronic system designers additional embedded power capabilities. In addition, the EnerChip batteries from the company enable new ideas in energy storage applications for ICs and unique solutions for medical, sensor, RFID, industrial control, communications, and portable electronic devices.

Their solid-state batteries, EnerChipTM, are made using semiconductor fabrication technologies to provide a rechargeable energy storage device that does not include any liquids, gels, or hazardous chemicals. The EnerChipTM devices can also be packed as a regular semiconductor component and co-packaged with other integrated circuits.

Cymbet has a diverse patent portfolio covers patentable aspects of materials, design, production, and applications.

In 2020, Axzon and Cymbet Corporation announced a collaboration to develop the world’s lowest power Internet of Things (IoT) sensor tag at a price point that enables constant monitoring and information logging of critical environmental factors during the logistics chain of perishable goods.

This groundbreaking sensing system includes Axzon’s Xerxes-II semi-passive data logger sensor IC for monitoring and recording temperature, pH, moisture, strain, and other environmental factors with Cymbet’s EnerChip solid-state micro-battery.

3. Prieto Battery

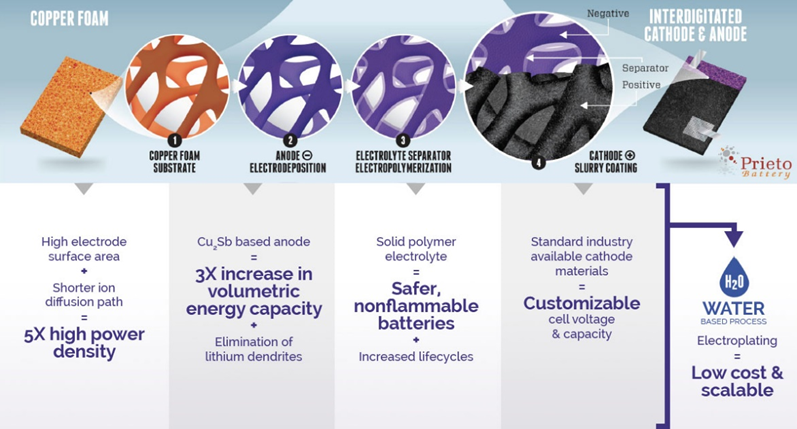

Based in the United States, Prieto Battery aims to develop a safe solid-state battery that has more energy and faster charging, is longer lasting, cheaper, and can be utilized in various applications and devices.

The 3D Full Cell from Prieto is a single device that combines ultracapacitor power and Li-ion energy storage. The device can decouple energy and power density and tailor it to each application, which is unachievable with a 2D structure.

Prieto intends to offer its 3D anode as a standalone product, a drop-in substitute for traditional anodes such as graphite. In the fall of 2019, these cells passed third-party safety testing and are an ideal solution for enabling Li-ion battery chemistry in medical devices where safety is critical.

Hercules Electric Vehicles and Prieto Battery, Inc. announced in 2020 that they had signed a Letter of Intent to form a strategic partnership to develop and commercialize Prieto’s 3D Lithium-ion solid-state batteries for use in Hercules electric pickups, SUVs, and other upcoming vehicles commencing in 2025.

Sodium-ion Batteries for Storage

4. BrightVolt

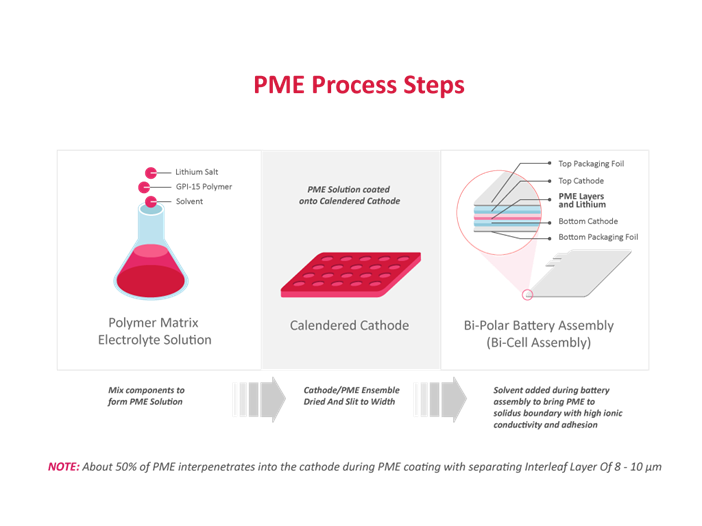

BrightVolt, based in the United States, is a leader in developing solid-state thin and flexible lithium polymer batteries. The company has sold approximately 15 million primary/non-rechargeable solid-state batteries globally. In addition, BrightVolt is currently working on a ground-breaking new “platform” solid-state polymer electrolyte for application in Secondary/Rechargeable Lithium-Ion batteries used in Consumer Electronics and e-mobility applications.

The company’s patented Polymer Matrix Electrolyte (PME®) technology enables batteries with 25% more energy density than existing Lithium-ion batteries while also making them cleaner, safer, and more ecologically friendly, all at a lower overall cost of manufacture.

5. Sakuu

Sakuu, headquartered in the US, innovates large-scale, environmentally friendly battery technology and manufacturing. Proprietary solid-state electrolyte and porous anode technology provide superior energy densities for maximum range and faster charge times.

Cypress™ Cell Technology of the company revolutionizes battery manufacturing by delivering high-energy-density batteries with exceptional safety features. It has energy densities ranging from 750 Wh/l to over 900 Wh/l, supporting 3C continuous discharge and peaks up to 10C.

These cells/batteries can achieve over 700 cycles with a 100% depth of discharge to an 80% state of health, proving its reliability and longevity. Cypress™ Cell is UN38.3 compliant, ensuring safety. The comprehensive manufacturing licensing package speeds up time to market and supports business growth.

The company rapidly prints these solid-state batteries from the transformational KavianTM platform in agile gigafactory settings. This enables mass-scale, cost-effective, and sustainable production to fulfill global cell demand.

Swift PrintTM solid-state batteries from the company provide best-in-class performance and safety in a recyclable and customizable package.

Sakuu’s 0.80% weekly growth rate confirms Cypress™ as a scalable solution. The Cypress™ Cell Technology package includes innovative features like Kavian™ printing, dry processes, mass volume, customization, and cost reduction, making it even more attractive to manufacturers.

The company has established a memorandum of understanding (MOU) with Japan’s NGK Spark Plugs in 2022. The MOU would allow NGK to co-develop and supply ceramic materials for Sakuu’s solid-state battery production, ranging from current battery material requirements at Sakuu’s California pilot line facility through at-scale commercialization for its AM solid-state battery line.

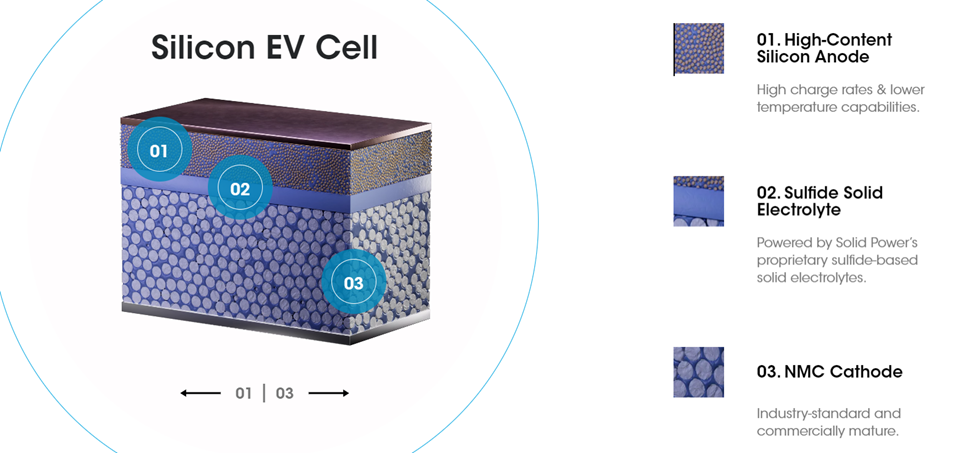

6. Solid Power

Based in the United States, Solid Power develops all-solid-state rechargeable batteries for electric vehicles and portable-bile power industries. Solid Power replaces a standard lithium-ion battery’s flammable liquid electrolyte with a proprietary sulfide solid electrolyte. As an outcome, Solid Power’s all-solid-state cells are safer and much more stable across a wide temperature range. They can provide a 50-75% increase in energy density over the best available rechargeable batteries.

The company’s technology offers higher energy capacity, enhanced safety, and cost advantages. It has achieved up to 500 Wh/kg in full-scale cell capacities of up to 100 Ah and a volumetric energy density of 930 Wh/l.

Under a memorandum of understanding (“MoU”) and joint development agreement (“JDA”) signed in 2021, Solid Power, Inc. entered into a partnership with SK Innovation Co to manufacture automotive-scale all-solid-state batteries. The collaboration is intended to enable the validation of Solid Power’s all-solid-state cell research and production procedures as part of the industry-standard automotive qualifying process.

According to Doug Campbell, CEO and Co-Founder of Solid Power, “The partnership with SK Innovation is designed to validate that Solid Power’s all-solid-state production processes are scalable and compatible with existing lithium-ion production technology. The ability to collaborate with a global leader in lithium-ion cell production is key to our go-to-market strategy and meet anticipated demand.”

Innovative Solid State Battery Startups

7. Enovix

Lithium-ion batteries face safety challenges against thermal runaway caused by internal shorts. Traditional batteries are prone to dangerous chain reactions that compromise safety when severely damaged.

Enovix’s BrakeFlow™ Technology mitigates these risks by enhancing tolerance against thermal runaway. Integrated into its 3D cell architecture, BrakeFlow™ minimizes potential internal short circuits, providing an additional layer of protection to reduce the likelihood of thermal runaway events. It improves battery safety by preventing overheating and hazardous chain reactions, ensuring safer operation, and reducing risks associated with lithium-ion batteries.

With a 100% active silicon battery design, Enovix achieves up to a 50% increase in capacity compared to other devices. This indicates positive market expectations and potential growth for Enovix. It demonstrates the market’s confidence in Enovix’s technology and its potential to address safety concerns while offering substantial performance improvements.

Additionally, Enovix’s technology provides better Lithium Plating Protection over graphite anode cells, resulting in a 140mV higher lithiation potential. It enables hotspot reduction and heat dissipation due to excellent thermal conductivity, nearly 5X cell thermal conductivity compared to similar pouch cells.

Investors like Eclipse Ventures, T. J. Rodgers, York Capital Management, Cypress Semiconductor, Intel Capital, Qualcomm Ventures, Sofinnova Investments, DCM Ventures, and Trinity Ventures support this solid battery company.

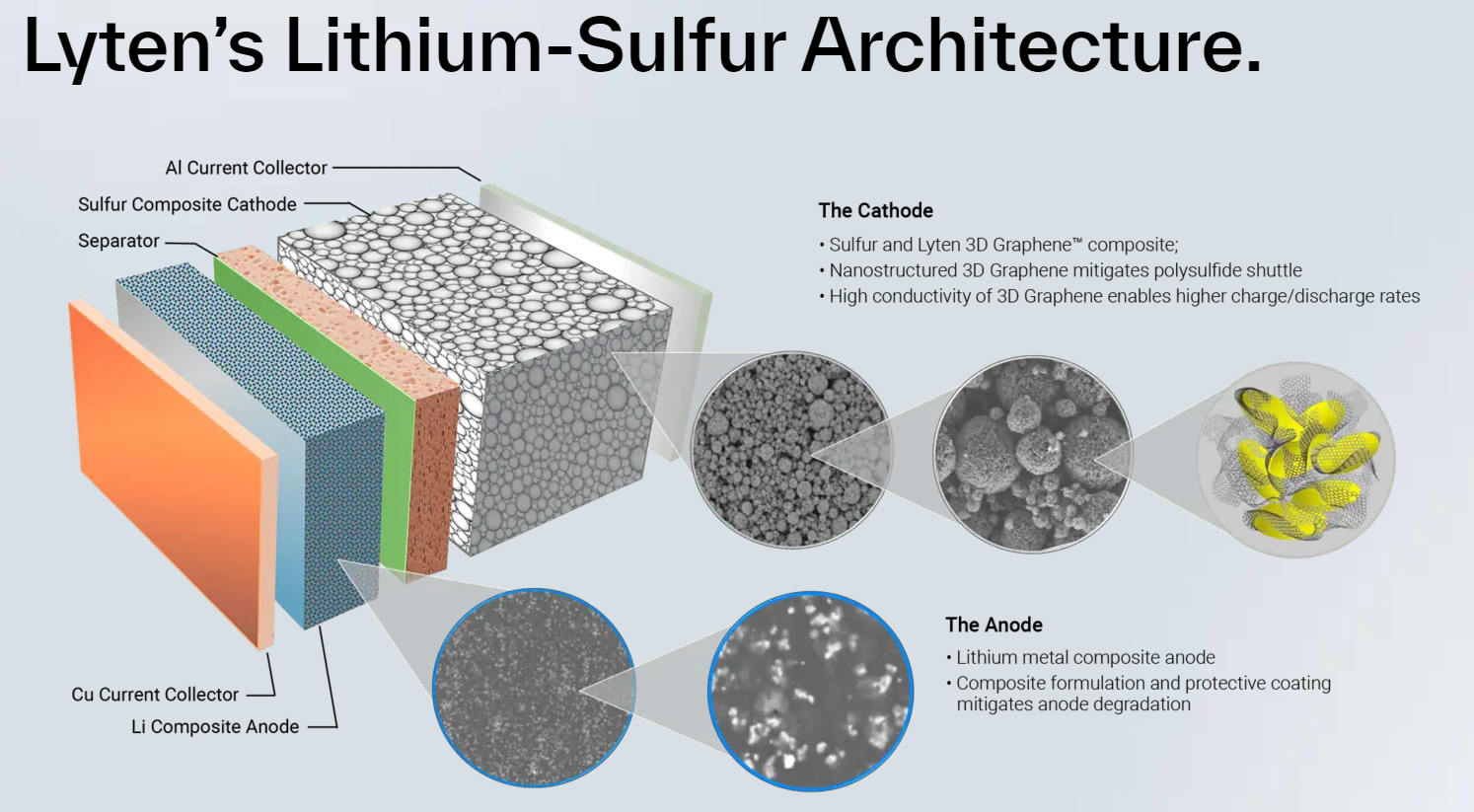

8. Lyten

Lyten is a cutting-edge materials science company based in San Jose, California, focused on transforming the battery industry with its innovative 3D Graphene technology.

The battery industry heavily depends on mined minerals for lithium-ion batteries, which complicates the supply chain and drives up costs. Traditional battery designs are prone to thermal runaway, posing serious safety risks. Additionally, composite materials’ excessive weight and plastic usage hinder efficiency and sustainability.

Lyten’s 3D Graphene technology addresses these critical issues, aiming to simplify the supply chain, reduce costs, mitigate safety risks, and decrease battery materials’ weight and plastic content. Its lithium-sulfur batteries powered by its 3D graphene technology offer higher energy density and safety. These batteries charge 80% in less than 20 minutes.

The company’s products leverage the unique properties of 3D Graphene to enhance performance and sustainability. Unlike conventional batteries that rely heavily on scarce and expensive mined minerals such as cobalt and nickel, Lyten’s lithium-sulfur batteries use abundant sulfur, making them more cost-effective and environmentally friendly. These batteries offer higher energy density, translating to longer-lasting power in a lighter package.

Lyten’s lithium-sulfur batteries are less prone to thermal runaway, a common safety concern in lithium-ion batteries, making them safer for a broader range of applications.

Its 3D Graphene is a supermaterial that converts greenhouse gases into solid carbon and hydrogen gas. The company also offers sensors and composite materials based on its 3D Graphene technology and material.

Lyten is backed by investors like US Department of Energy, Walbridge, Stellantis Ventures, Honeywell, Prime Movers Lab, FedEx, Triatomic Capital, and Amazon Web Services.

9. SES AI Corporation

SES AI is a pioneering battery technology company headquartered in Woburn, Massachusetts, specializing in developing next-generation Li-Metal batteries. SES AI is at the forefront of innovation, combining advanced materials and artificial intelligence to create higher energy density, faster charging times, and enhanced safety compared to traditional lithium-ion batteries.

SES AI’s Li-Metal batteries offer over 400 Wh/kg and 1,000 Wh/L capacity, providing an extended range for EVs and eVTOL aircraft. These batteries have ultra-thin Li-Metal anode that reduces battery weight, enhancing overall efficiency.

The company integrates advanced technologies, such as battery health monitoring algorithms that ensure the safety and longevity of the batteries. Additionally, their large-format Li-metal cell engineering supports scalability and performance in larger applications.

SES AI also implements Mine-to-Man artificial intelligence (AI) software, optimizing the entire battery value chain from resource extraction to recycling, enhancing efficiency and sustainability.

Honda Motor, SAIC Motor, SK, Hyundai Motor Company, Applied Materials, General Motors, Tianqi Lithium, Kia Motors, Temasek Holdings, and Fidelity Canada are among top investors in SES AI.

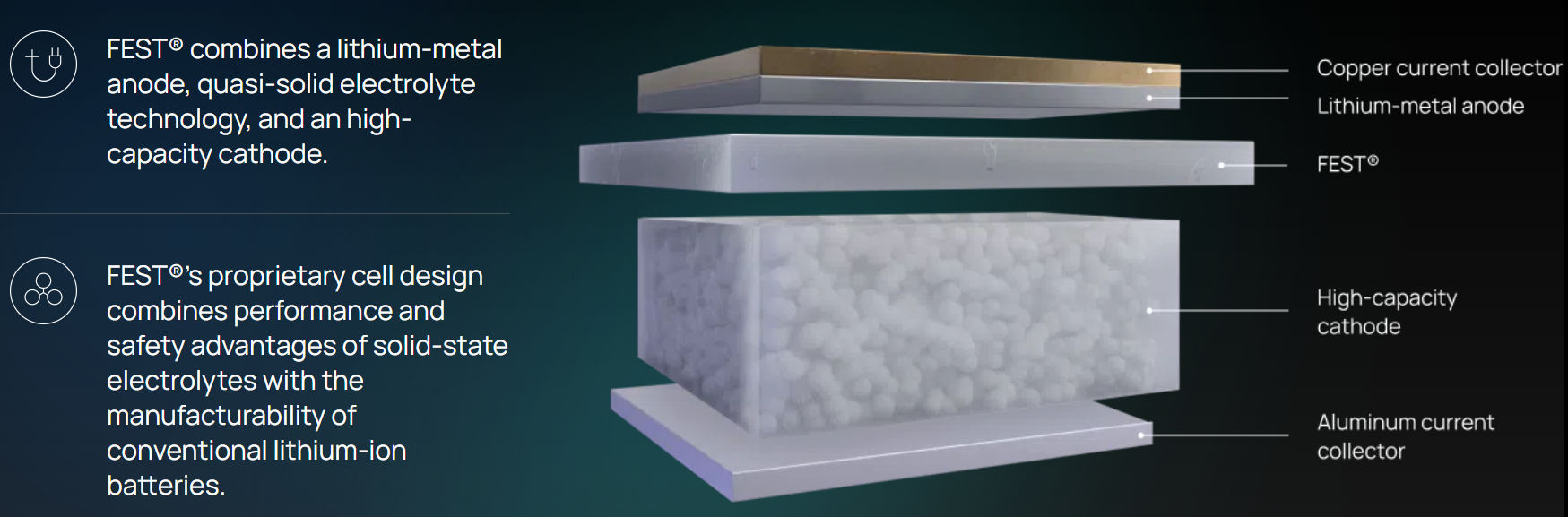

10. Factorial Energy

Factorial Energy is an innovative battery technology company based in Woburn, Massachusetts, dedicated to advancing solid-state battery technology. Specializing in developing high-performance FEST® batteries, Factorial Energy is addressing critical challenges in the energy storage industry, including enhancing energy density, improving safety, and reducing the weight of batteries.

Unlike traditional lithium-ion batteries, Factorial’s solid-state technology offers superior performance and safety by utilizing a solid electrolyte, eliminating the risks associated with flammable liquid electrolytes.

Factorial Electrolyte System Technology (FEST®) revolutionizes battery tech, especially solid-state batteries. With a target range of 600+ miles, it extends battery life significantly while reducing weight by 40% and size by 33%, saving space.

The company prioritizes safety, aiming for top ratings and surpassing current limitations to enhance performance, sustainability, and safety. It’s a clean energy solution for EVs, homes, and businesses, easing concerns about power depletion. FEST® excels in flexibility, compatibility, and application versatility with lithium-metal, specialized electrolytes, and cathodes.

Industry giants like Mercedes Benz, Stellantis, Kia Motors, Hyundai Motor Company, Gatemore Capital Management, Eden Rock Group, and WAVE Equity Partners back it.

Conclusion

Investments in Solid State Batteries are boosting. Battery makers and automotive companies like Toyota, Nio, BMW, and Volkswagen are investing in SSB technology. Moreover, Solid State Battery startups are also collecting funding to improve SSBs for different applications.

In the initial seven months of 2024, China’s production capacity for solid-state batteries soared past 142 gigawatt-hours, driven by an influx of investments exceeding 64.4 billion yuan (approximately $9 billion). The strategic moves of several key domestic battery manufacturers fuel this rapid expansion. Companies like CATL are significantly boosting their investments, with plans to commence small-scale production by 2027.

Meanwhile, Sunwoda, a pioneer in solid-state battery research since 2015, is advancing its development of high-energy batteries, aiming to deliver next-generation cells with energy densities of up to 500 watt-hours per kilogram. Additionally, Gotion High-Tech has unveiled a new solid-state battery with a cell energy density of 350Wh/kg, marking a 40% improvement over traditional lithium-ion batteries.

Looking ahead, the future of the solid-state battery industry is not just promising—it is poised for transformative growth. According to a report by Market Research Future, the global solid-state battery market is expected to grow at a CAGR of 28% from 2022 to 2030, reaching a market value of approximately $6 billion by the end of the decade. This growth is driven by the increasing demand for safer, more efficient energy storage solutions, particularly in the electric vehicle (EV) sector.

As these technologies scale, the solid-state battery industry is expected to play a pivotal role in global efforts to reduce carbon emissions and accelerate the adoption of electric vehicles and renewable energy solutions.

GreyB specializes in helping businesses navigate the complexities of innovation and intellectual property.

Partnering with a team like GreyB’s ensures you uncover growth opportunities, safeguard your IP, and stay ahead in today’s competitive landscape. Our deep expertise in technology scouting, competitive analysis, and market research empowers you to make informed decisions confidently.

We don’t just offer insights—we provide actionable strategies tailored to your unique needs, ensuring your innovation efforts are protected and strategically aligned with the future.

At GreyB, the complexities of staying ahead in today’s innovation landscape are well understood. We’re passionate about treating your challenges as our own, and our mission is to uncover the most valuable opportunities for your business. To see how we’ve helped other companies thrive, visit our case studies page or reach out to explore how we can collaborate on your next big move.

How Can We Help You?

We work with top R&D and IP teams to solve complex challenges. Let us know what you’re working on, and we’ll bring our expertise to the table.