SWOT analysis of Polylactic acid [Includes Existing Solutions to drawbacks of PLA]

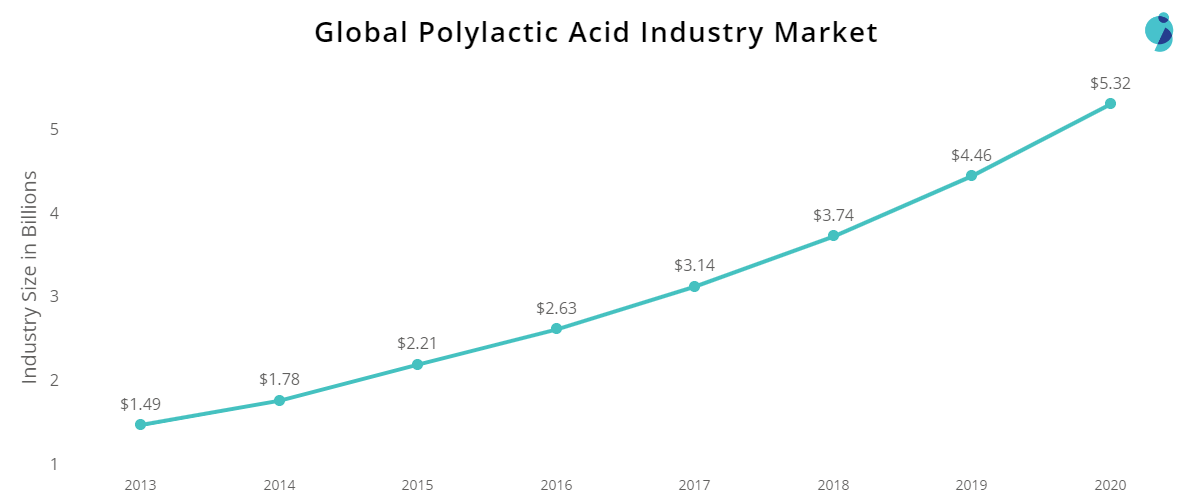

Polylactic acid (PLA) is a widely used material in packaging, especially food packaging. Derived from renewable sources like cornstarch, cassava roots, chips, starch, and sugarcane, this bioplastic is anticipated to be adopted as the primary biodegradable material used in packaging in the near future. For that very reason, the global market for PLA is expected to reach more than $5 billion by the end of 2020.

PLA is biodegradable under certain circumstances, as enzymes like Proteinase K, which can catalyze the hydrolytic degradation of PLA, are not available in the environment except on rare occasions. That is why there have been multiple research studies on various blends of PLA to improve its biodegradability. On the plus side, PLA commonly uses cornstarch as a raw material, which is available in abundance and biodegradable.

But is it the best material for your packaging?

Let’s conduct a SWOT analysis to find out.

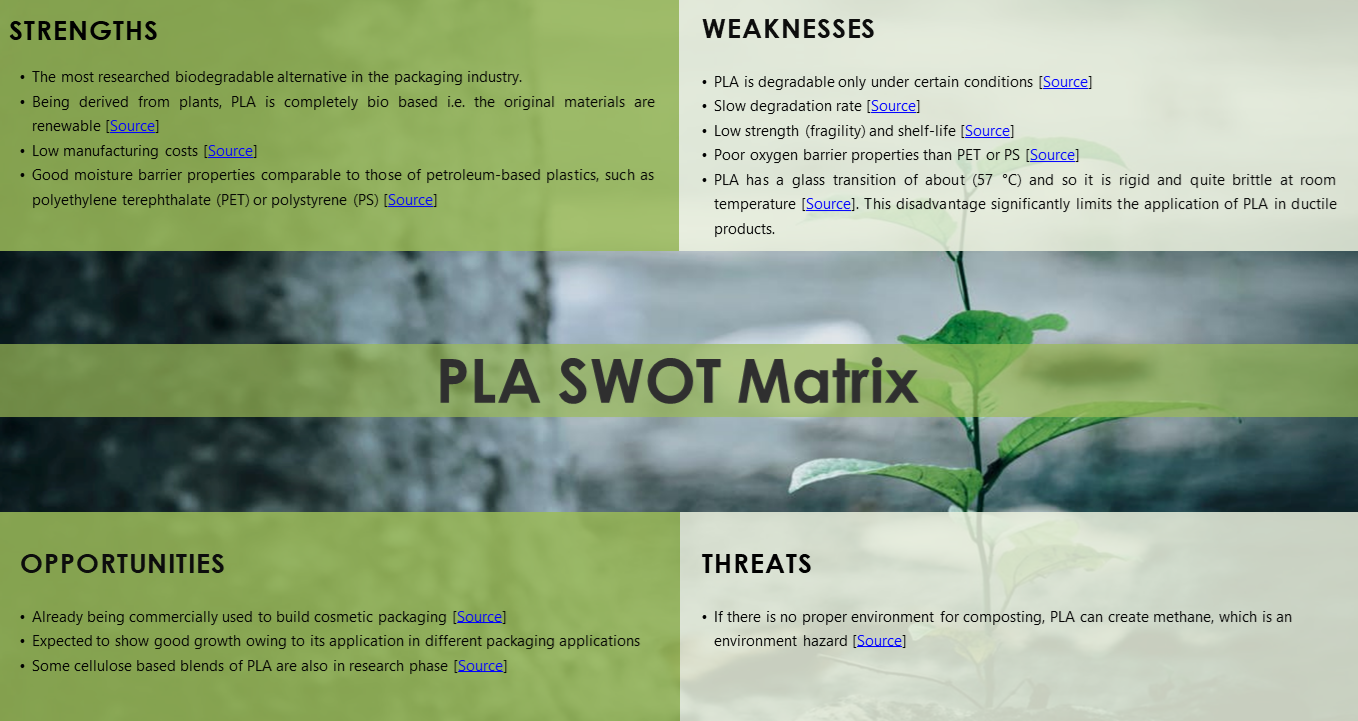

SWOT Analysis of PLA

Strengths

Being one of the most commonly used materials for packaging, research has seen a surge in improving the material. Not just companies but universities across the world are researching Polylactic acid to make sustainability a reality.

Below are some of the strengths of PLA:

- The most researched biodegradable alternative in the packaging industry [Source].

- Being derived from plants, PLA is completely bio-based, i.e., the original materials are renewable. [Source]

- Low manufacturing costs [Source]

- Good moisture barrier properties comparable to those of petroleum-based plastics, such as polyethylene terephthalate (PET) or polystyrene (PS) [Source]

Weaknesses

The main weaknesses of PLA are recycling, composting, and usage.

As PLA materials need to be composted rather than recycled, like paper and cardboard, companies need to separate the PLA materials and the regular recyclable materials. Currently, there are only just over a hundred composting facilities in the US.

Although PLA materials can be composted, the correct conditions must exist. If the material is deposited in a landfill without the proper oxygen and light, the PLA material may not decompose for decades.

PLA materials can be used for many applications, but this does not compare to the uses of the more common plastic – polyethylene terephthalate (PET), which is used to make bottles consumers use every day.

Below are some of the weak points of PLA:

- PLA is degradable only under certain conditions [Source] and has a slow degradation rate [Source]

- Low strength (fragility) and shelf-life [Source]

- Poor oxygen barrier properties than PET or PS [Source]

- PLA has a glass transition of about 57 °C, so it is rigid and quite brittle at room temperature [Source].

Opportunities

As companies are trying to adopt a green solution for the sake of sustainability, there are still opportunities for businesses to seize that lies in PLA. Also, due to their different properties and ongoing research, companies can use the material for applications other than packaging.

Below are some of the opportunities of PLA:

- Already being commercially used for packaging [Source]

- Expected to show good growth owing to its application in different packaging applications.

- Some cellulose-based blends of PLA are also in the research phase [Source]

Threats

Being a biodegradable material, there are some threats to using PLA, and it pertains to the environment.

That is, if there is no proper environment for composting, PLA can create methane, which is an environmental hazard [Source].

Also, substances that are toxic in nature, like plastic, if inhaled or absorbed in the skin or eyes in vapor or liquid form, could cause serious health issues (especially during the manufacturing process).

Solutions to Weaknesses of PLA

Due to its different properties, PLA also has different weaknesses. However, given its huge potential, companies are trying to devise solutions to overcome those limitations of PLA.

Below listed are a few of them.

Weakness

Low strength (fragility) and shelf-life [Source]

Solution

Total S.A., under the name of Fina Technology Inc., has filed a couple of patents that seem to counter this particular weakness of PLA. US10125249B2 and US9796842B2 – both these patents discuss a biodegradable polystyrene blend that is strong enough to be used in a wide variety of applications including cosmetics. There isn’t any explicit indication however that this blend is in commercial use.

CJ Cheil Jedang Corp, a South Korean food company, has a patent [US9328239B2] about a biodegradable blend of PLA containing polyhydroxyalkanoates, improving reproducible mechanical properties for the overall composition.

Weakness

PLA is degradable only under certain conditions [Source]

Solution

A Netherland-based sustainable packaging company called BioFutura has developed a proprietary crystalline PLA [CPLA] material that is a combination of PLA [70-80%] and chalk [20-30%] and other biodegradable additives. According to the EN-13432 composting standard, CPLA products are 100% biodegradable and compostable – i.e., in an industrial composting facility under optimum conditions (oxygen, moisture, and heat), the PLA will be fully composted in 8-12 weeks.

Weakness

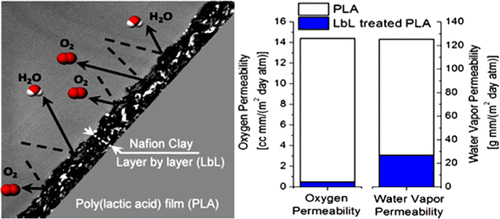

Poor oxygen barrier properties than petroleum-based plastics, such as polyethylene terephthalate (PET) or polystyrene (PS)

Solution

In a research paper, Federico Carosio et al. [Source] discussed a layer-by-layer deposition technique on commercially used PLA thin films (30 μm thick), which can increase their barrier properties to oxygen and water vapor.

Conclusion

We talked about the strengths and weaknesses of PLA, such as biodegradability, renewability, moisture barrier property, fragileness, poor oxygen barrier property, etc.

These properties, as you can see, are mostly related to the food and beverage industry.

But, there are other industries for which PLA could prove a better solution than the existing one.

For those industries, properties such as oil barrier, grease barrier, heat resistance, elasticity, and other mechanical properties matter more than what we have discussed.

This should lead to questions like:

- What does the SWOT Matrix of other properties of PLA look like?

- To what extent is it commercialized?

- Is there a way around already available to overcome its weakness?

- Who is holding IP on the material and commercializing it, and where?

Also, an important one:

- What are the other available alternatives to PLA and their SWOT Matrices?

which can be answered. If you are looking for answers to any of the questions above or something similar related to sustainable packaging and looking for a solution:

Authored by: Sukha Singh, Team Lead, Patent Landscape

![SWOT analysis of Polylactic acid [Includes Existing Solutions to drawbacks of PLA] SWOT analysis of Polylactic acid [Includes Existing Solutions to drawbacks of PLA]](https://www.greyb.com/wp-content/uploads/bfi_thumb/dummy-transparent-qbpqwpc6sq0zkr5vtunflogb7fb8t4o5mmoaha5u2g.png)